Abs operation, Axle control, Dolly-axle control (select low) – Bendix Commercial Vehicle Systems MC-30 TRAILER ABS CONTROLLER User Manual

Page 7: Steer axle option (mod2 select low), Side control, Normal braking, Diagnostic led display of confi guration, Modulator chuff test at power-up

7

ABS OPERATION

The MC-30

™

controller uses wheel speed sensors, ABS

modulator-valves and an ECU to control trailer wheels by

axle or by side. By detecting excessive wheel slip during

braking and adjusting the pressure to each brake chamber,

the MC-30

™

controller is able to optimize slip between the

tire and the road surface. The EC-30T

™

controller controls

the ABS modulator-valves, similar to a driver pumping the

brakes. However, the MC-30

™

controller is able to pump the

brakes on the vehicle with greater speed and accuracy.

Axle Control

MC-30

™

controller axle control will utilize a single ABS

modulator-valve to control wheels from both sides of a

given axle or axles. In the case of an unbalanced braking

surface, axle control will control the high coeffi cient wheel

just under the lock limit. Temporary periods of wheel lock

are permitted on the low coeffi cient wheel. Axle control

should not be used on 5th wheel dollies or steerable axles.

When braking on even surfaces, an axle-control system

will perform similar to a side control, two modulator system.

Axle control is available in 2S/1M, 2S/2M and 4S/2M

installations.

Dolly-Axle Control (Select Low)

MC-30

™

controller dolly-axle control will utilize a single

ABS modulator-valve to control wheels from both sides of

a given axle or axles. In the case of an unbalanced braking

surface, dolly-axle control will control the low coeffi cient

wheel just under the lock limit. Optimal vehicle stability

is achieved by not allowing the high coeffi cient wheel to

sustain wheel lock. When braking on even surfaces, a dolly

axle control system will perform similar to side control or

axle control system. Dolly axle control is only available in

2S/1M installations.

Steer Axle Option (MOD2 Select Low)

This option causes MOD2 to be Dolly-Axle controlled and

is only active while confi gured for 4S/2M Axle control. This

confi guration option should be set when MOD2 is installed

on a forward or steer axle of a full trailer. Steer Axle option

can be set using a diagnostic tool or by purchasing an

MC-30

™

controller unit with this option pre-set.

Side Control

The MC-30

™

controller will utilize a single ABS modulator-

valve to control one or more wheels on a given vehicle side.

In the case of an unbalanced braking surface, MC-30

™

controller side control will individually control each side just

under the lock limit. Side control is available in 2S/2M and

4S/2M installations.

Normal Braking

During normal braking, the MC-30

™

controller functions as

a standard relay valve. As brakes are applied or released

by the driver, the control signal from the tractor foot valve

causes the M-30T

™

modulator-valve to apply proportional

pressure to the trailer brake chambers.

If a PLC tractor and PLC trailer are powered at the same

time, the MC-30

™

controller will also trigger a bulb check

on the tractor dash using PLC.

Diagnostic LED Display of Confi guration

At power-up, the diagnostic LEDs all illuminate, then display

the current confi guration for sensors, modulators and ABS

control. See chart 3. After displaying the confi guration,

only the green VLT LED will stay on. However, if a fault is

detected, the faulted component will be displayed by the

red diagnostic LEDs.

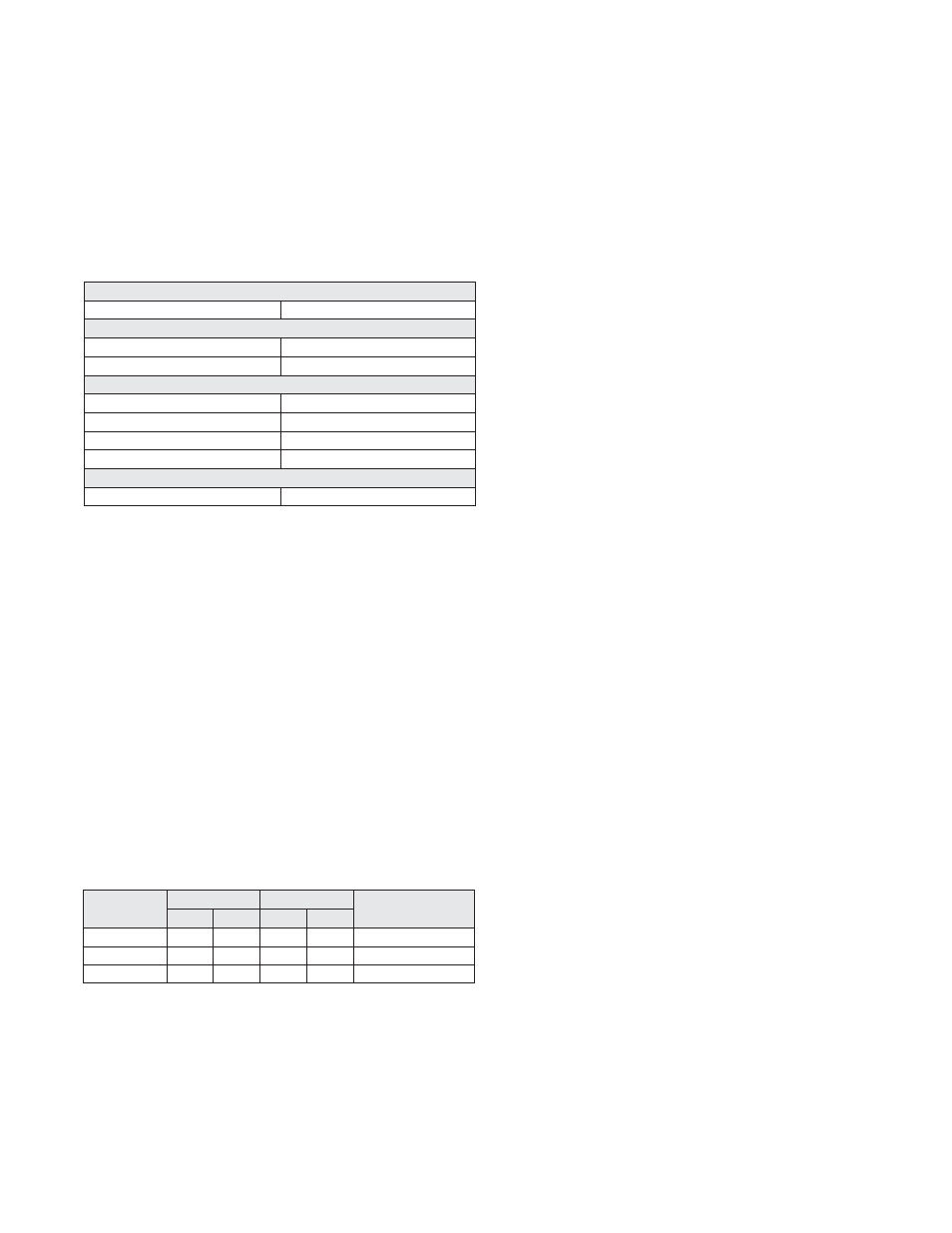

CHART 4 - MC-30

™

CONTROLLER ABS CONFIGURATIONS

System

Sensors Modulators Available

Confi

guration

2 4 1 2

ABS

Control

Settings

2S/1M

X X Axle

or

Dolly-Axle

2S/2M X X Axle

or

Side

4S/2M X X Axle

or

Side

CHART 3 - LED POWER-UP SEQUENCE

MC-30

™

Controller – LED Power-Up Sequence

At

power-up All

LEDs

1st blink displays number of wheel speed sensors

2

Sensors

SEN-FRT

4

Sensors

SEN-RER-FRT

2nd blink displays modulator confi guration

1 Modulator (Dolly-Axle control)

MOD

1 Modulator (Axle control)

MOD-FRT

2 Modulators (Axle control)

MOD-RER-FRT

2 Modulators (Side control)

MOD-LFT-RHT

Normal Operation

No Faults

VLT (green) LED illuminated only

Modulator Chuff Test at Power-Up

At power-up, the MC-30

™

controller activates a modulator

chuff test. This electrical and pneumatic ABS modulator

test can assist the technician in verifying that the modulator

wiring and installation are correct. With brake pressure

applied, a properly installed modulator will cause fi ve

rapid audible chuffs of air pressure. If two modulators

are installed, the MC-30

™

controller activates 5 chuffs at

Modulator 1 (MOD 1) then Modulator 2 (MOD2). The chuff

sequence is then repeated.

If the modulator is wired incorrectly, the modulator will only

produce one chuff, or no chuff at all. If an issue is detected

during the modulator chuff test, compare the modulator

wiring and plumbing to the MC-30

™

controller’s electrical

system schematic and make repairs. See Figures 16 and

17.