Baumfolder BAUM1620 Gapset Calibration User Manual

Page 12

12

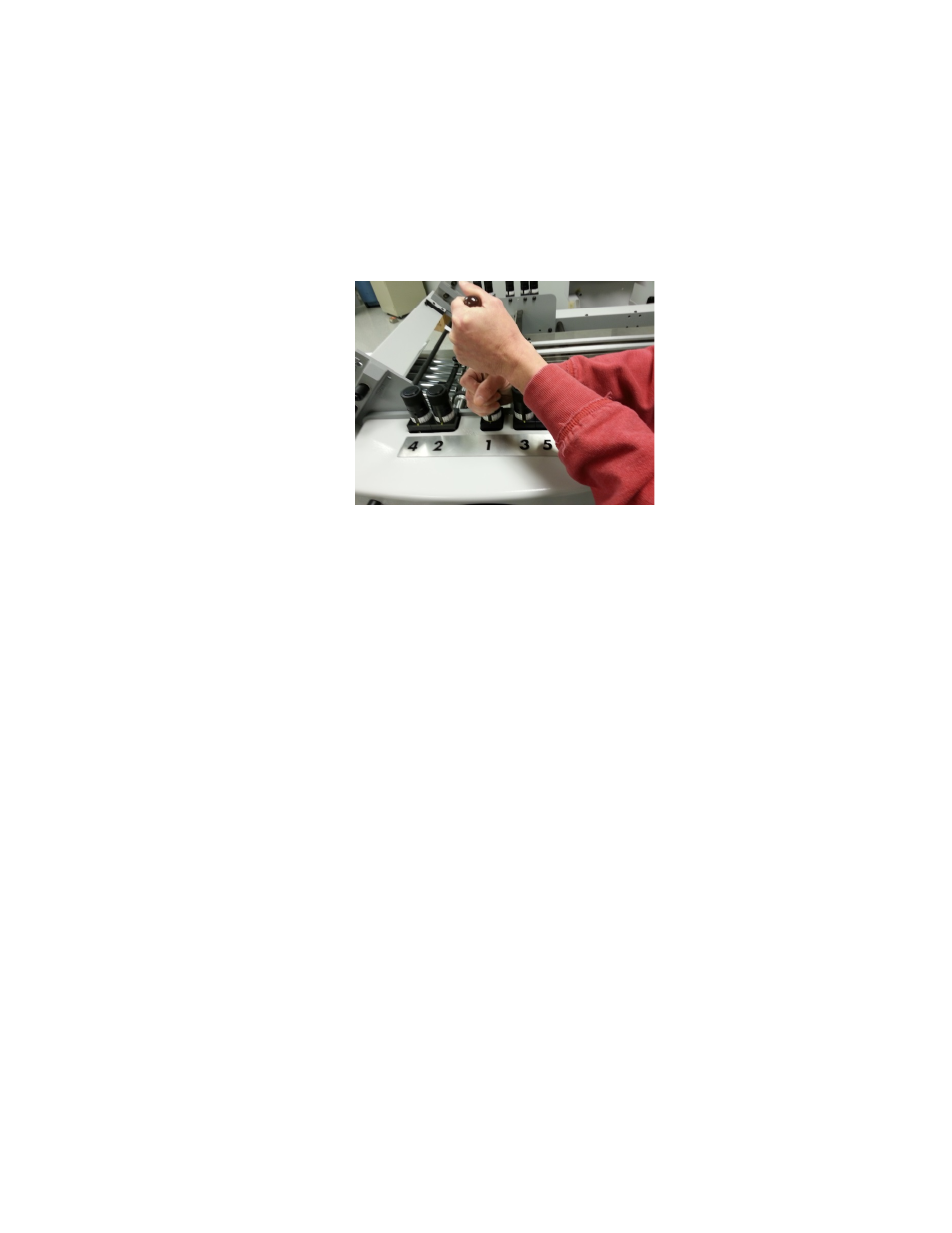

7. While holding the gapset knob so it does not turn, tighten the elastic stop nut located in the

cavity

of

the

gapset

knobs

slowly

to

ensure

that

it

just

contacts

the

gapset

knob.

This

is

done

using

a

1/2”

or

13mm

nut

driver.

Do

this

for

all

gapset

knobs.

Do

not

torque

this

nut

onto

the

gapset

knob,

only

tighten

this

nut

until

it

just

touches

the

gapset

knob!

These

nuts

on

top

of

the

gapset

knobs

serve

2

purposes:

a) With the nuts just tightened until they are just touching the gapset knobs while

the

gapset

is

set

in

between

1

&

15,

the

operator

can

now

adjust

the

fold

roll

pressures

for

running

a

thinner

stock

than

20#

bond

such

as

Bible

paper,

etc.

b) If the operator is able to set the gapsets to a gapset setting greater than 15, the

operator

can

just

turn

the

gapset

knob

counter-‐clockwise

until

it

contacts

this

nut.

The

operator

can

then

turn

the

knob

clockwise

until

a

gapset

setting

of

1.

The

fold

roll

pressure

for

this

roll

should

now

be

set

for

a

single

sheet

of

20#

bond

paper.

8. Turn all of the gapset knobs back to 1. It is recommended that you check the fold roll pressures

of

all

fold

rolls

by

using

1”

wide

strips

of

20#

bond

paper

ad

doing

the

pull

test.

IF

the

fold

roll

pressures

remained

the

same

with

all

gapset

knobs

set

at

1,

then

you

may

proceed

to

the

next

step.

If

the

fold

roll

pressures

do

not

feel

correct,

it

will

be

necessary

to

repeat

steps

4

-‐

6

to

properly

set

the

fold

roll

pressures.

9. The gapset knob caps can now be pressed into the top of the gapset knobs.

10. The gapset calibration is now complete.