Bryant 4-WAY MULTIPOISE FIXED-CAPACITY CONDENSING GAS FURNACE 345MAV User Manual

Page 5

1. Turn off gas and electrical supplies to furnace.

2. Remove main furnace door.

3. Disconnect wires or connectors to rollout switch, gas valve,

ignitor, and flame sensor.

CAUTION:

Label all wires prior to disconnection when

servicing controls. Wiring errors can cause improper and

dangerous operation.

4. Disconnect combustion-air intake pipe from intake housing.

5. Remove the pressure switch tube from intake housing.

6. Remove screws attaching intake housing to burner box, and

rotate intake housing away from burner box for removal.

7. Using backup wrench, disconnect gas supply pipe from gas

valve.

8. Disconnect pressure tubing from gas valve.

9. Remove 2 screws attaching top filler panel and rotate

upwards to gain access to screws attaching burner box to

cell panel.

10. Remove screws attaching burner box to cell panel. (See Fig.

5.)

NOTE:

Burner box cover, manifold, gas valve, and burner

assembly should be removed as 1 assembly.

11. Clean heat exchanger openings with a vacuum and a soft

brush. (See Fig. 6.)

NOTE:

After cleaning, inspect the heat exchangers to ensure they

are free of all foreign objects that may restrict flow of combustion

products.

12. Reverse items 4 through 10 for reassembly.

WARNING:

The ground wire from the gas valve MUST

be attached to the burner box attachment screw. Failure to

attach this ground wire to an adequate casing ground will

cause the furnace control to lock out.

NOTE:

Be sure burner box gasket is installed between burner box

and cell panel. If gasket is damaged, replace it.

NOTE:

Inspect combustion-air intake housing. If foamed gasket

was removed, check for any damage. If gasket is damaged in any

way, it must be repaired. To repair, remove damaged gasket

section, apply sealant releasing agent such as PAM cooking spray

or equivalent (must not contain corn or canola oil, aromatic or

halogenated hydrocarbons or inadequate seal may occur) to burner

box and apply a small bead of G.E. RTV 162, G.E. RTV 6702, or

Dow-Corning RTV 738 sealant to edge of combustion-air intake

housing. (See Fig. 7.)

13. Refer to furnace wiring diagram and connect wires to

rollout switch, gas valve, ignitor, and flame sensor.

14. Reconnect pressure switch tubes to gas valve and intake

housing. Refer to tube routing label on main furnace door

for proper tube location. Be sure tubes are not kinked. (See

Fig. 8.)

15. Turn on gas and electrical supplies to furnace.

16. Check furnace operation through 2 complete heat operating

cycles. Look through sight glass in burner enclosure to

check burners. Burner flames should be clear blue, almost

transparent. (See Fig. 9.)

17. Check for gas leaks.

WARNING:

Never use matches, candles, flame, or

other sources of ignition to check for gas leakage. Use a

soap-and-water solution. Failure to follow this warning

could result in a fire, personal injury, or death.

18. Replace main furnace door.

B.

Secondary Heat Exchangers

NOTE:

The condensing side (inside) of the secondary heat

exchangers CANNOT be serviced or inspected. A small number of

bottom outlet openings can be inspected by removing the inducer

assembly. See Flushing Collector Box and Drainage System

section for details on removing inducer assembly.

V.

FLUSHING COLLECTOR BOX AND DRAINAGE

SYSTEM

1. Turn off gas and electrical supplies to furnace.

2. Remove main furnace door.

3. Disconnect inducer motor and pressure switch wires or

connectors.

4. Disconnect pressure switch tubes.

5. Disconnect vent pipe from inducer housing outlet by

loosening coupling clamp on inducer outlet.

6. Disconnect drain tube from inducer housing. (See Fig. 8.)

7. Remove inducer housing assembly by removing 4 bolts

attaching assembly to cell panel.

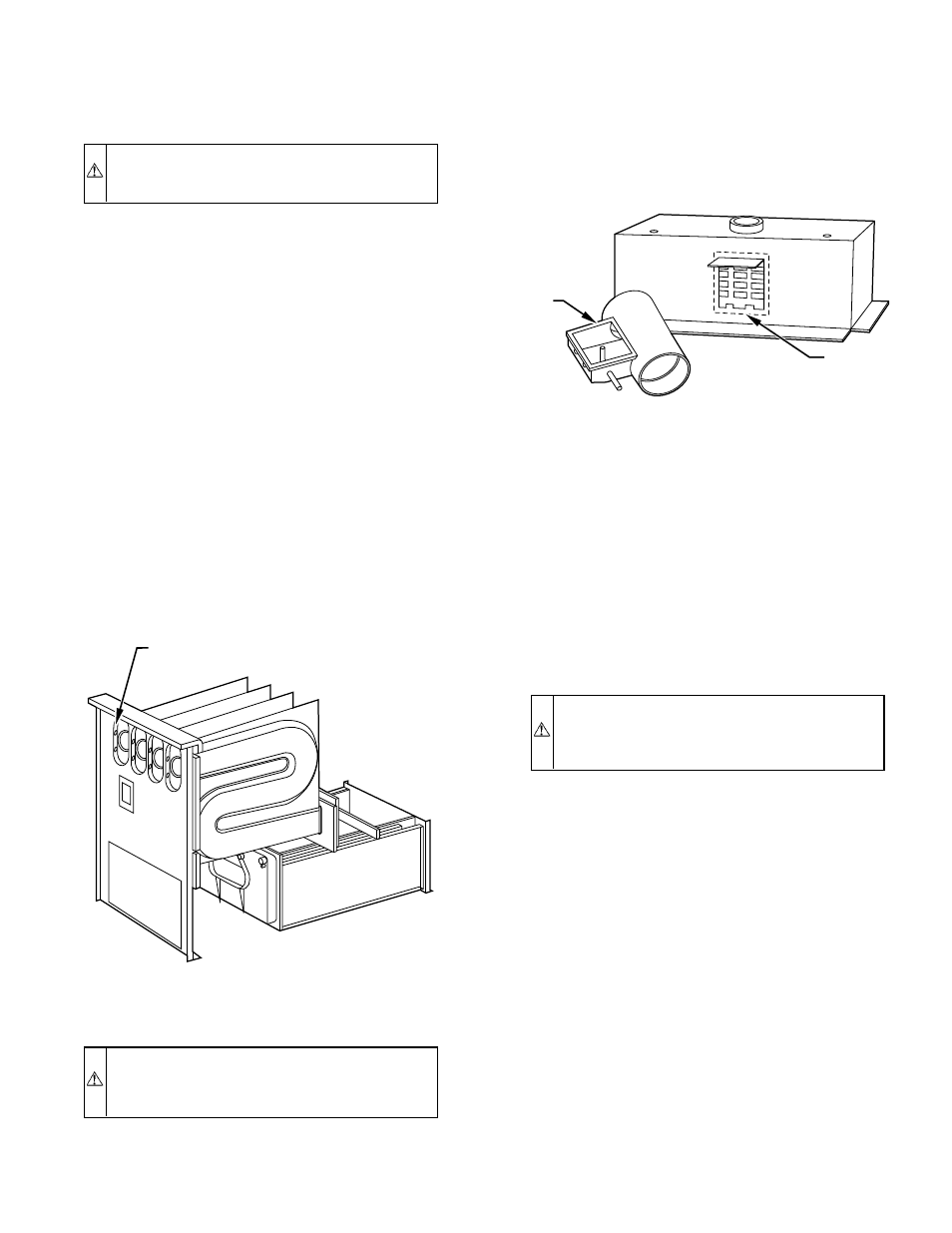

Fig. 6—Cleaning Inlet Openings of Primary Heat

Exchangers

A93080

PRIMARY HX

INLET OPENINGS

Fig. 7—Combustion-Air Intake Housing Gasket

Repair

A93087

PAM

RTV

—5—

→