Ac o c /ac o c h, Selection procedure – Thermal Transfer Systems Air ACOC Series User Manual

Page 3

AC

O

C

/AC

O

C

H

262.554.8330

www.thermaltransfer.com

144

A

IR C

O

O

L

E

D

AC

O

C

(H

)

selection procedure

step 1

Determine the Air Compressor’s motor horsepower.

step 2

Enter the chart at the motor horsepower to select the

correct model.

step 3

Check the aftercooler sCFM. The SCFM of air discharged from

the air compressor must be equal to or less than the value in the

chart for the model selected. If it is not, choose a larger model.

If the SCFM is unknown, multiply the air compressor’s motor

horsepower by 4.5 to determine the SCFM capacity required.

Recommended Typical Installation

1. Support piping as needed. Flexible connectors must be properly installed

to validate warranty.

2. Coolers should not operate in ambient temperatures below 35°F (1°C).

Consult factory for recommendations.

3. The fan cannot be cycled.

4. AHP coolers operated outdoors must be protected from weather.

Consult factory for recommendations.

5. If ductwork or additional static resistance is added to the cooler airstream,

an auxiliary air mover may be required.

sizing

1. Oil flow is .45 GPM/HP.

2. Oil pressure drop - 15 psi or less

3. Oil heat transfer based on 100°F E.T.D.

(E.T.D. = Entering Temperature Difference)

(E.T.D. = Oil in Temperature - Ambient Air Temperature)

4. Air aftercooler pressure drop - 3 psi or less.

5. E.T.D. Temperature Correction Factor:

HPchart = HPcompressor x

100

Desired E.T.D.

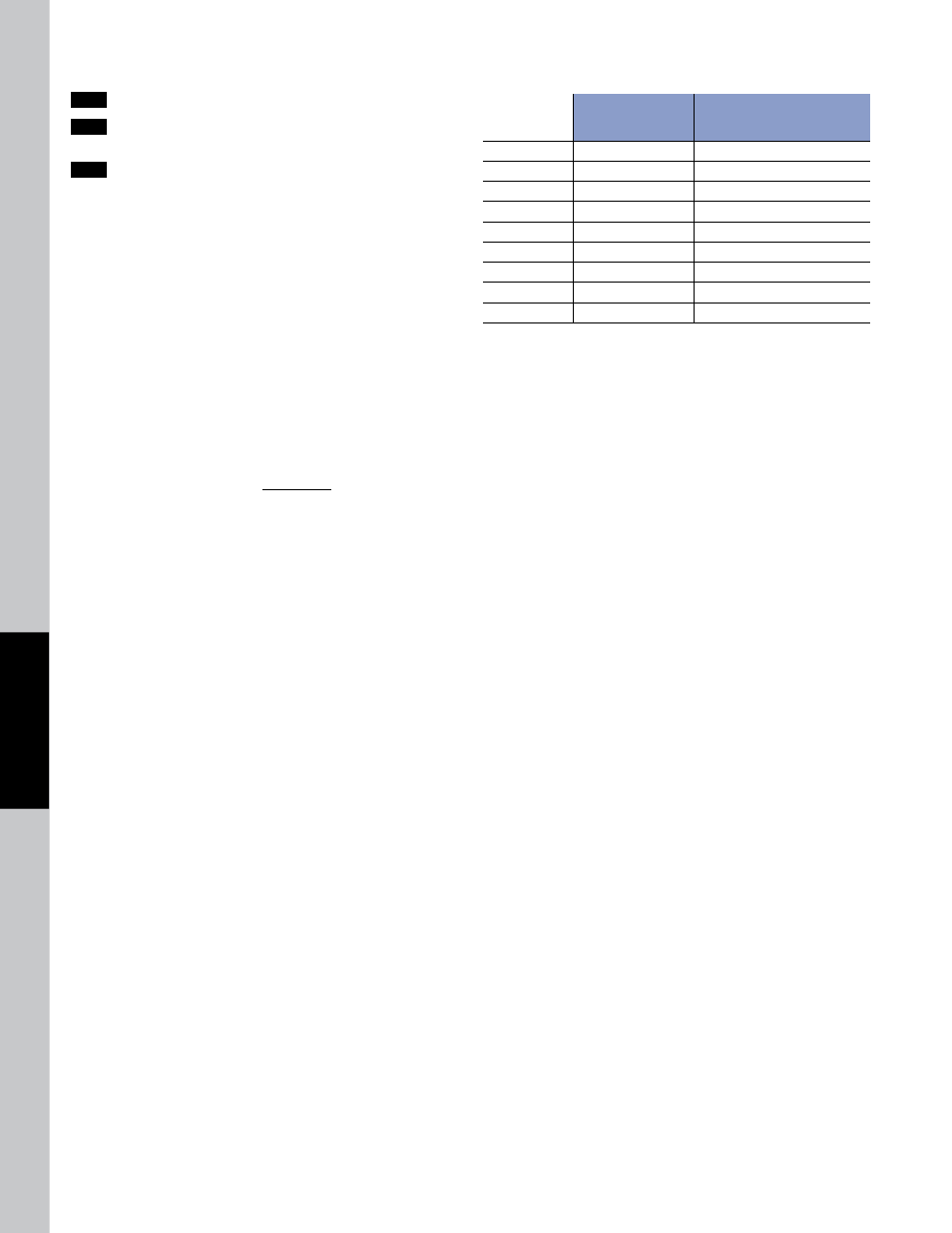

Aftercooler Maximum sCFM

with 100 Psi Air & A 15°F

Model

Compressor H.P.

Approach Temperature

ACOC(H)-400 15-35

175

ACOC (H)-725

40-55

275

ACOC (H)-950

60-85

425

ACOC (H)-1200

90-120

600

ACOC (H)-1600

125-155

775

ACOC (H)-2000

160-225

1125

ACOC-2500 230-275

1375

ACOC-3000 280-325

1625

ACOC-3500 330-360

1800

maintenance

Periodic cleaning of the fins with compressed air is needed to remove the

accumulation of dirt and dust. Check the automatic drain on the separator

(not included) periodically.

If the inside of the tubes need to be cleaned of oil and carbon, use a

chlorinated solvent. Do not use strong solvents. Do not use acids or

caustic cleaners.