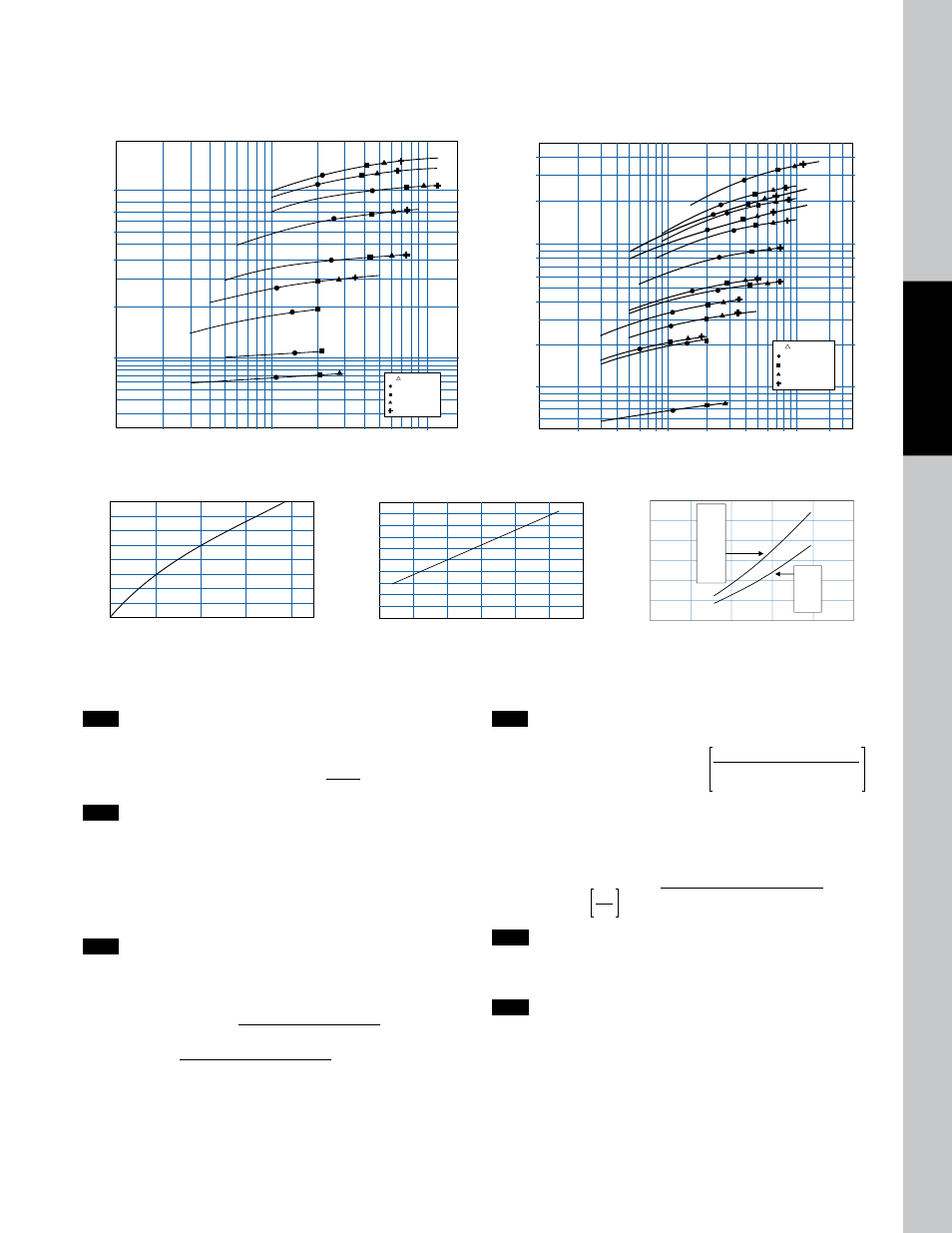

Performance curves selection procedure, Ma models with dc fan assemblies, Ma models – Thermal Transfer Systems MA Series User Manual

Page 4: No fan, core only), C e.t.d (°c) x correction factor

MA

www.thermaltransfer.com

262.554.8330

63

A

IR C

O

O

L

E

D

MA

Performance Curves

Selection Procedure

step 1

determine Heat load. Typical Rule of Thumb, - size cooler for

1/3 of the input horsepower. Heat load may be expressed as either

Horsepower or BTU/HR or KW/°C.

HP = BTU/HR ÷ 2545

BTU/HR = HP x 2545

step 2

determine entering temperature difference. (Actual E.T.D.)

(E.T.D.= Entering oil temperature – Entering Ambient air temperature)

The entering oil temperature is generally the maximum desired system

oil temperature.

Entering air temperature is the highest Ambient Air temperature the

application will see, plus – add any pre-heating of the air prior to its

entering the cooler. Pay special attention if air is drawn from the

engine compartment for cooling.

step 3

Find air Velocity Correction Factor

(Skip to Step 4 if using our DC Fan Assembly)

Calculate actual SFPM Air Velocity or SCFM (Standard Cubit Feet per

Minute) for selection using the Face Area from the table.

SFPM Air Velocity* = SCFM Air Flow

Square Feet Cooler Face Area

SMPM = SCMM

Square Meter Cooler Face Area

(SCFM Air Flow= SFPM Air Velocity x Square Feet Cooler

Face Area)

*If the Air Velocity calculated is different than the value in Step 4,

then recheck Corrected oil Pressure drop.

step 4

determine the Corrected Heat dissipation to use the Curves

englisH Version

Corrected (BTU/Hr) 100°F

Heat Rejection

=

Heat Load x Desired Air Velocity

†

E.T.D

x

Correction Factor

(BTU/HR) to use with selection chart

(Air Factor value not needed if using provided DC Fan assembly;

Omit in formula)

metriC Version

Corrected Heat

Heatload (kw)

Rejection KW =

Desired Air Velocity

°C

E.T.D (°C) x Correction Factor

step 5

select model From Curves Enter the Performance Curves at the

bottom with the GPM oil flow and proceed upward to the adjusted

Heat Rejection from Step 4. Any Model or Curve on or above this point

will meet these conditions.

step 6

Calculate oil pressure drop Find the oil pressure drop

correction factor and multiply it by the Oil Pressure Drop found

on performance curve.

Listed Performance Curves are based on:

• 50 SSU (11 cSt) oil

• 1000 Standard Feet per Minute (SPFM) (304.8 MPM) Air Velocity

• 100° F (55.56° C) Entering Temperature Difference (E.T.D.)

If your application conditions are different, then continue with the

selection procedure.

BTU/HR = KW x 1895 x E.T.D.(°F)

°C

1

(3.79)

Heat Rejection BTU/HR @ 100F ETD

Oil Flow GPM (LPM)

MA-12-4A/B

MA-4-4A/B

MA-3-4A/B

MA-18-4A/B

MA-32-4A/B

100,000

200,000

10,000

1,000

20,000

40,000

60,000

80,000

Heat Rejection KW/C

0.5

1.1

0.05

0.005

0.1

0.2

0.3

0.4

2

(7.57)

20

(75.71)

40

(151.42)

60

(227.12)

80

(302.83)

100

(378.54)

4

(15.14)

6

(22.71)

8

(30.28)

10

(37.85)

MA-232-4A/B

MA-48-4A/B

MA-248-4A/B

= 5 PSI

= 10 PSI

= 15 PSI

= 20 PSI

(0.34 BAR)

(0.69 BAR)

(1.03 BAR)

(1.38 BAR)

Oil P

MA-3.5-4A/B

MA Models with DC Fan Assemblies

50 150 250 350

450

5.0

4.5

4.0

3.5

3.0

2.5

2.0

1.5

1.0

Viscosity (SSU)

Co

rr

ec

tio

n

Fa

ct

or

Pressure Drop

oil pressure drop Correction

0

500

1000

1500

2000

2500

3000

(152.4)

(304.8)

(457.2)

(609.6)

(762.0)

(914.4)

2.0

1.8

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0.0

Face Velocity SFPM (smpm)

Co

rr

ec

tio

n

Fa

ct

or

Air Static

air static Correction

MA-4

MA-12

MA-18

MA-32

MA-48

MA-66

MA-82

MA-120

MA-232

MA-248

MA-3

MA-3.5

MA-8

MA-14

MA-20

0

500

1000

1500

2000

2500

(152.4)

(304.8)

(457.2)

(609.6)

(762.0)

3.00

2.50

2.00

1.50

1.00

0.50

0.00

Face Velocity FPM (mpm)

Air Static inH2O

76.2

63.5

50.8

38.1

25.4

12.7

0.00

Air Static mmH20

Air Static Pressure Drop

air static pressure drop

performance data Curve

10,000

5,000

20,000

40,000

60,000

80,000

100,000

200,000

300,000

400,000

500,000

0.05

0.03

0.1

0.2

0.3

0.4

0.5

1.1

1.6

2.1

2.6

MA-120

MA-82

MA-66

MA-48

MA-32

MA-20

MA-18

MA-14

MA-12

MA-8

MA-4

MA-232

MA-248

MA-3

= 5 PSI

= 10 PSI

= 15 PSI

= 20 PSI

(0.34 BAR)

(0.69 BAR)

(1.03 BAR)

(1.38 BAR)

Oil P

Heat Rejection BTU/HR @ 100F ETD

Heat Rejection KW/C

Oil Flow GPM (LPM)

1

(3.79)

2

(7.57)

20

(75.71)

40

(151.42)

60

(227.12)

80

(302.83)

100

(378.54)

4

(15.14)

6

(22.71)

8

(30.28)

10

(37.85)

200

(757.08)

400

(1514.16)

MA Models

(No Fan, Core Only)

performance data Curve