Ao h m, Selection procedure – Thermal Transfer Systems AOVHM Series User Manual

Page 4

AO

H

M

www.thermaltransfer.com

262.554.8330

47

A

IR C

O

O

L

E

D

A

OHM

/A

OV

HM

Selection Procedure

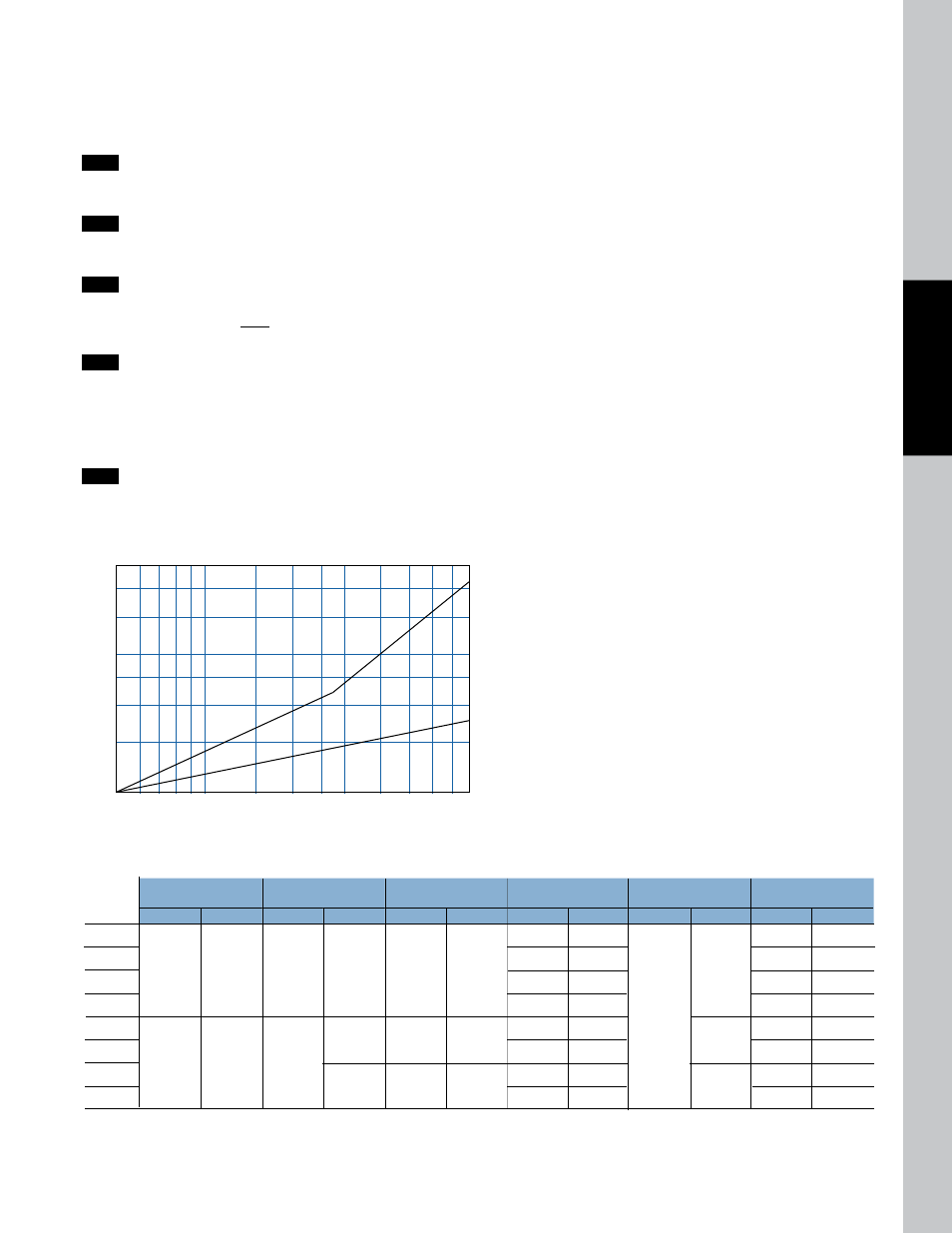

Performance Curves are based on 50 SSU oil entering the cooler 50°F higher

than the ambient air temperature used for cooling. This is referred to as a

50°F E.T.D.

Step 1

Determine the Heat Load. Heat load may be expressed as either

horsepower or BTU/Hr. To convert horsepower to BTU/Hr.:

BTU/HR = Horsepower x 2545

Step 2

Determine Entering Temperature Difference. The entering oil

temperature is generally the maximum desired oil temperature.

Entering oil temperature – Ambient air temperature = E.T.D.

Step 3

Determine the Corrected Heat Dissipation to use the curves.

Corrected Heat Dissipation =

BTU/HR heat load x 50°F

E.T.D.

x viscosity correction A.

Step 4

Enter curves at oil flow through cooler and curve heat dissipation.

Any curve above the intersecting point will work.

NOTE: Performance curves shown are for 1 and 2 pass

configuration.

EXAMPLE: 35 - 2 is AOHM or AOVHM - 35

Step 5

Determine Oil Pressure Drop from Curves:

l

= 5 PSI; n = 10 PSI; s = 20 PSI. Multiply pressure drop from

curve by correction factor B found in oil viscosity correction curve.

Desired Reservoir Temperature

Oil Temperature: Oil coolers can be selected using entering or leaving oil

temperatures.

Off-Line Recirculation Cooling Loop: Desired reservoir temperature is

the oil temperature entering the cooler.

Return Line Cooling: Desired reservoir temperature is the oil temperature

leaving the cooler. In this case, the oil temperature change must be

determined so that the actual oil entering temperature can be found.

Calculate the oil temperature change (oil

#

T) with this formula:

Oil

#

T = (BTU’s/Hr.) / (GPM Oil Flow x 210).

To calculate the oil entering temperature to the cooler, use this formula:

Oil Entering Temp. = Oil Leaving Temp + Oil

#

T.

Oil Pressure Drop: Most systems can tolerate a pressure drop through the

heat exchanger of 20 to 30 PSI. Excessive pressure drop should be avoided.

Care should be taken to limit pressure drop to 5 PSI or less for case drain

applications where high back pressure may damage the pump shaft seals.

Oil Temperature

Typical operating temperature ranges are:

Hydraulic Motor Oil

120°F - 180°F

Hydrostatic Drive Oil

160°F - 180°F

Engine Lube Oil

180°F - 200°F

Automatic Transmission Fluid

200°F - 300°F

Hydraulic Motor

MODEL

SIZE

MAXIMUM FAN SPEED

(RPM)

68

68

69

70

72

75

76

78

1725

5

10

15

20

25

30

35

40

AOHM

AOVHM

1140

3450

1725

AOHM

AOVHM

AOHM

AOVHM

1.6

1.1

3.3

3.4

5.2

300

400

900

300

500

1000

OIL FLOW REQUIRED

(GPM)

MIN. OPERATING

PRESSURE (PSI)

AOHM

AOVHM

SOUND dB(A)*

85

85

91

91

81

84

89

91

.22

MOTOR (in

3

/rev.)

DISPLACEMENT

AOHM

AOVHM

.22

.45

.70

AOHM

AOVHM

CFM

465

669

956

1460

2160

2990

4370

5450

780

1110

1590

2168

3000

4095

5921

9609

Notes: Maximum pressure is 2000 psi. Stated minimum operating pressure is at inlet port of motor. 1000 psi allowable back pressure.

*Catalog db(A) sound levels are at seven (7) feet. dB(A) sound levels increase by six (6) dB(A) for halving this distance and decrease by (6) dB(A) for doubling this distance.

OIL VISCOSITY CORRECTION MULTIPLIERS

A

B

VI

SC

OS

IT

Y

CO

RR

EC

TI

ON

OIL VISCOSITY SSU

6

5

4

3

2.5

2

1.5

1

50 60 65 70 75 80 90 100 200 300 400 500 600 700 800