Performance curves, Recirculation loop, 1 oil to water ratio – lowest water usage – Thermal Transfer Systems EK Series User Manual

Page 8

EK

www.thermaltransfer.com

262.554.8330

79

W

A

T

E

R C

O

O

L

E

D

EK

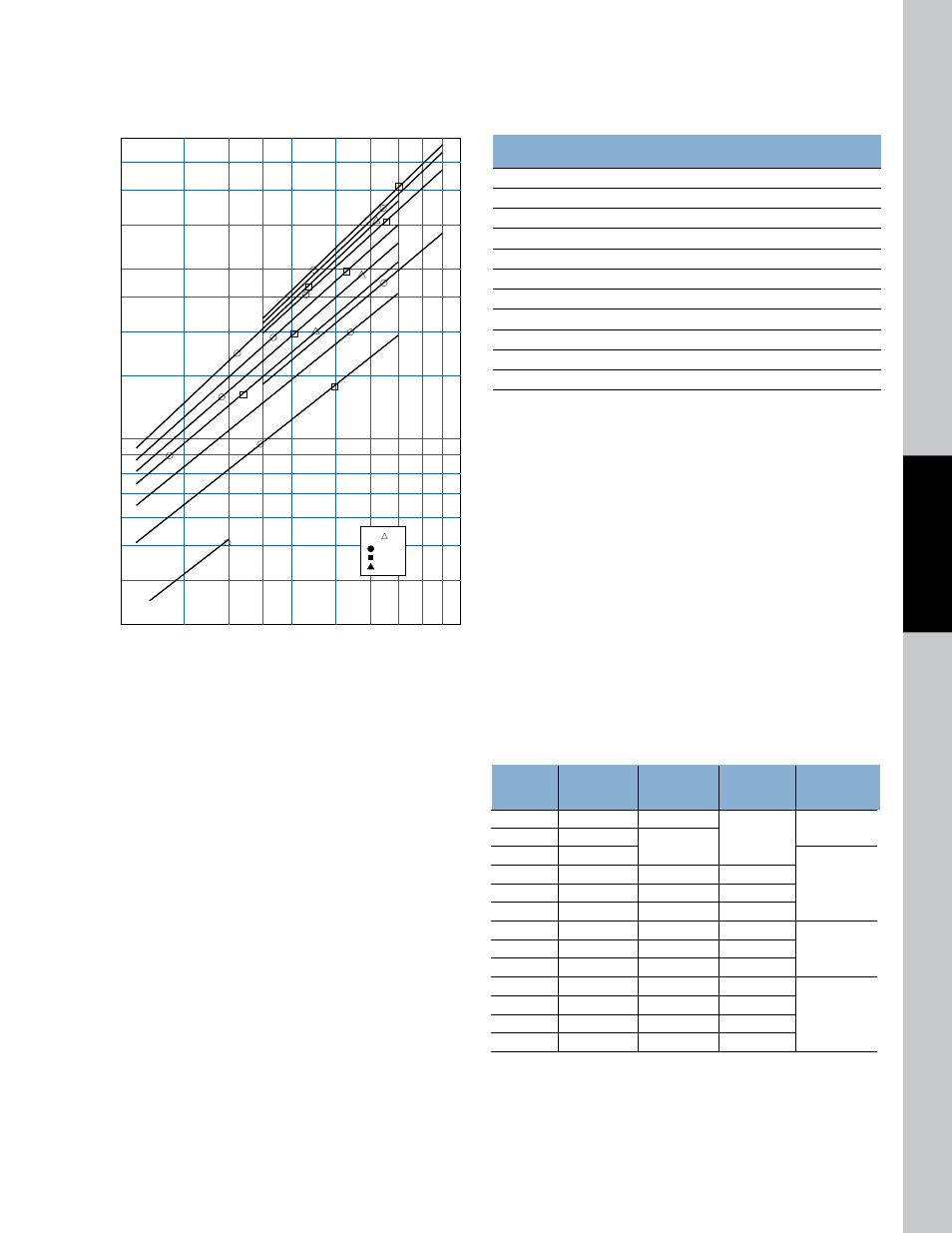

Performance Curves

10:1 Oil to Water Ratio – Lowest Water Usage

Weights (lbs)

Models

net

Approx. Shipping

1. EK-508-T

7

8

2. EK-708-F

15

16

3. EK-712-F

18

19

4. EK-714-F

19

20

5. EK-718-F

22

23

6. EK-724-F

26

28

7. EK-736-F

34

36

8. EK-1012-F

35

37

9. EK-1014-F

50

55

10. EK-1036-9-F

67

85

11. EK-1048-8-F

78

95

10

15

20

25

30

40

50

60

70

8

9

10

15

20

25

30

40

50

60

70

7

6

5

3

4

80

●

●

●

●

●

●

●

●

●

●

●

■

■ ▲

■

■

■

■

■

▲

▲

1

2

3

4

5

6

7

11

10

9

8

OIL FLOW (GPM)

HORSEPOWER REMOVED IN COOLER

OIL P

= 5 PSI

= 10 PSI

= 20 PSI

Recirculation Loop

Water Cooled Hydraulic Oil Coolers

BASiS:

n

40°F Entering temperature difference (Maintain reservoir 40°F

above the incoming water temperature)

n

Heat removal 30% of input horsepower

n

Hydraulic system flow (GPM) x 3 = Gallons; reservoir size

n

1 GPM cooler flow per HP heat to be removed

n

Turn-over reservoir 3-4 times per hour

n

Maximum flows

Minimum

Minimum

System

required GpM required GpM Heat exchanger

Horsepower

Hp Heat load

oil Flow

Water Flow

Model number

3

.9

1

EK-505-T

5

1.5

2

1

7.5

2.25

10

3

3

1.5

15

4.5

4.5

2

EK-512-T

20

6

6

3

25

7.5

7.5

4

30

9

9

4.5

EK-712-T

40

12

12

6

50

15

15

7.5

60

18

18

9

EK-1012-T

75

22.5

23

12

100

30

30

15