Figure 5 typical hanger & support spacing, Figure 6 end plate hanger/elbow installation – Schwank STSp-WP User Manual

Page 12

SP-MSWP-BX-09A

STSp-WP Manual

RD: MAY 2004

RL: 9

KH

Page 8

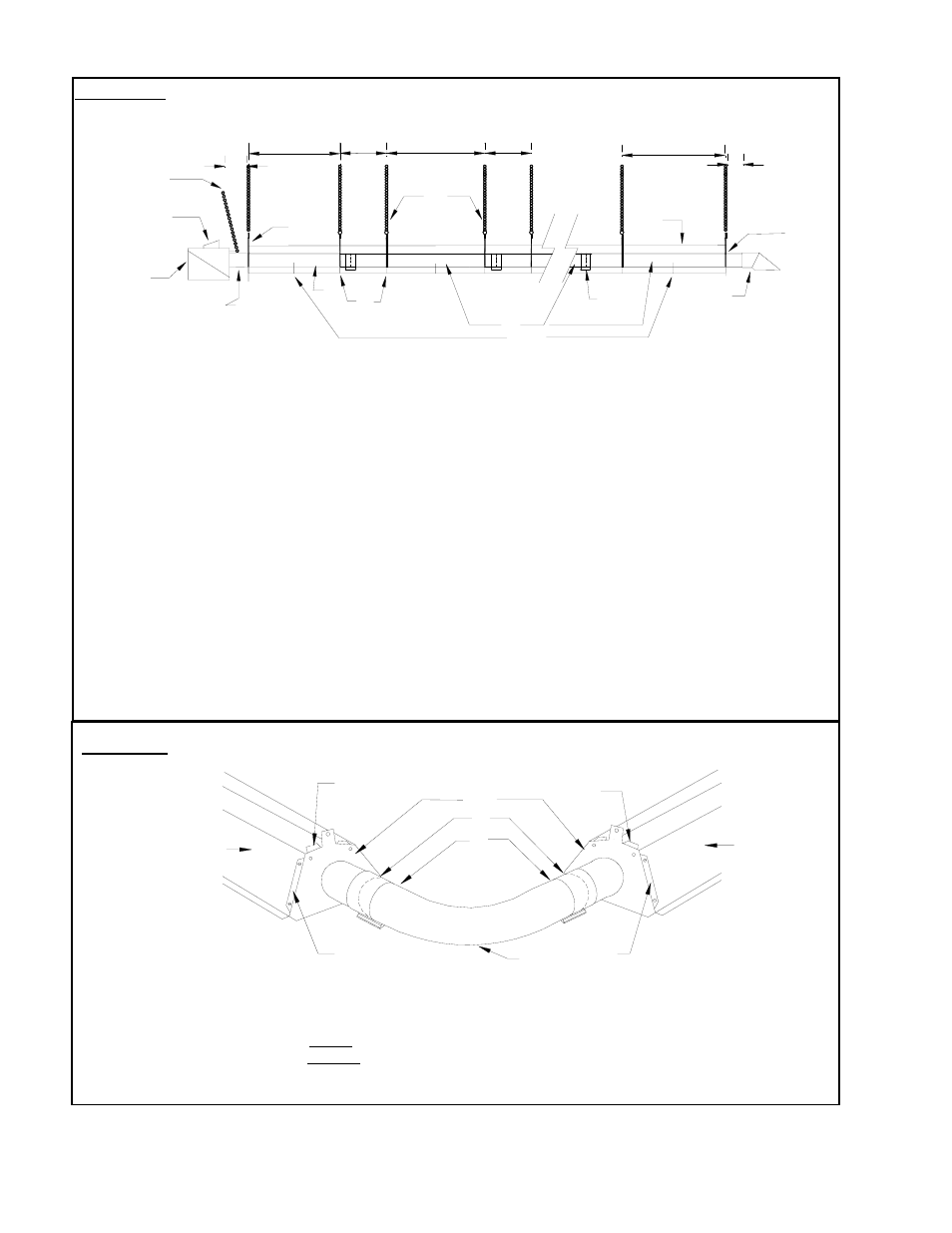

FIGURE 5 TYPICAL HANGER & SUPPORT SPACING

5. Sight Glass

6- Aluminized Tube with Flange

7– Tube Coupler

8- Painted Steel Tube(s)

1.End Plate Hangers

2- Wire Hangers

3- Burner Assembly

4- Combustion Air Intake

9– Focus shield Reflector ***

10- Flue Vent terminal

11- Burner Support Chain****

12- Hanger Support Chains

13- Reflector Stabilizer **

FIGURE 6

END PLATE HANGER/ELBOW INSTALLATION

1

. End-Plate-Hangers 5. 90

0

(shown) or 180

0

Elbow

2. Focus Shield Reflectors 6. Tube/Elbow Coupler

3. End-Plate-Hanger Flange OVER Reflector elbow 7. Point at which Swaged tube fits into elbow

4. End Plate Hanger Flange UNDER Reflector and Swaged end of elbow fits into tube.

1

2

2

3

3

4

4

5

6

7

10

13

2

11

4

3

5

6

8

7

9

1

1

12

3"

4"

"ALL TUBES MUST BE SUSPENDED BY TWO (2) HANGERS PER 10' LENGTH,

MOUNTED APPROXIMATELY 6" TO 12" IN FROM EACH TUBE END.

Note Exception: First and last hanger (end plate hangers) must be mounted 4” away from end of tube

* Distances shown are recommendations and may be varied to match field requirements.

** This should only be used if the reflector is mounted on an angle.

*** Refer to section 9: Focus Shield Reflector Installation (page 11).

**** The angle is very critical