Caution – Schwank SER(IR) User Manual

Page 16

GP-MSER-BX-11A

SER / IR Manual

RD: March 2006

RL: 11A

KH

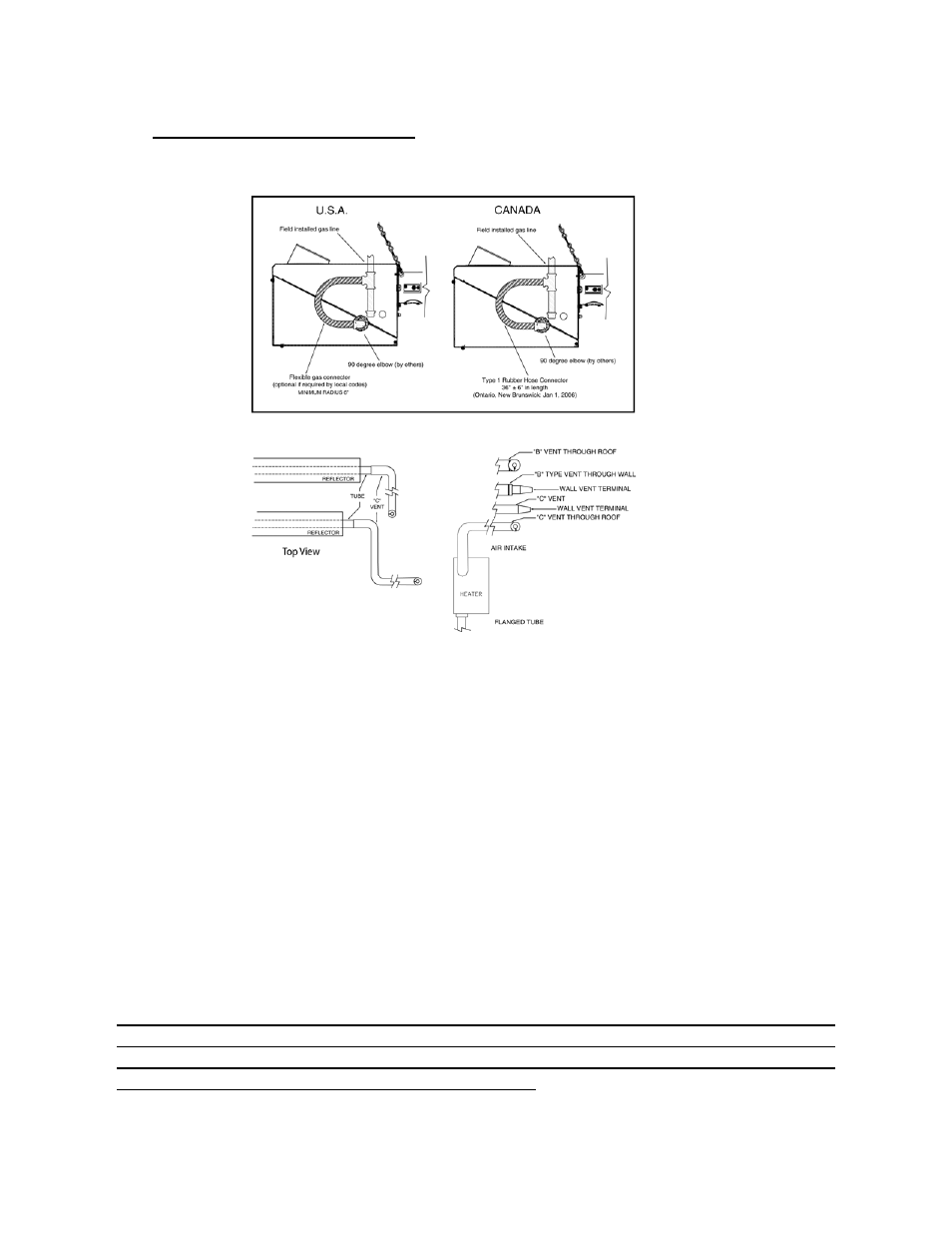

11. GAS SUPPLY INSTALLATION

It is recommended that the approved flexible connector be installed between the heater and gas

piping. CANADA : B-149.1-05 Section 7.22.3; U.S.A. as per local or national code.

If rigid connection is made, compensation for normal gas supply piping expansion and ra-

diant tube expansion must be provided. All piping must conform to local codes.

During any pressure testing of the gas- supply piping system. The heater must be isolated from

the gas-supply piping system by closing its individual manual shutoff valve, supplied by in-

staller.

DO NOT use pressures greater than 1/2 psig. to pressure-check the heater.

TEST FOR LEAKS: All gas piping and connections must be tested for leaks after the installa-

tion is completed, by applying soap suds solution to all connections and joints. If bubbles ap-

pear, leaks have been detected and must be fixed.

DO NOT USE A MATCH OR OPEN FLAME OF ANY KIND TO TEST FOR LEAKS.

NEVER OPERATE THE HEATER WITH ANY LEAKING CONNECTIONS.

The supply system should be checked first with heater turned "OFF" followed by another check

with heater turned "ON".

IMPORTANT:

The minimum supply-line pressure at the inlet to the heater regulator must not, in any in-

stance, be lower than 5.0 inches of water column pressure, for natural gas ,and 11.0 inches

of water column pressure for propane gas. The supply-line pressure must be checked with

all heaters and appliances operating in the building. A sealed regulator is supplied with

the heater to maintain the proper manifold pressure when the main burner is operating.

Page 12

CAUTION: