Yes no, Page 2, Page 35 right right right wrong wrong – Schroth Racing AutoControl User Manual

Page 4

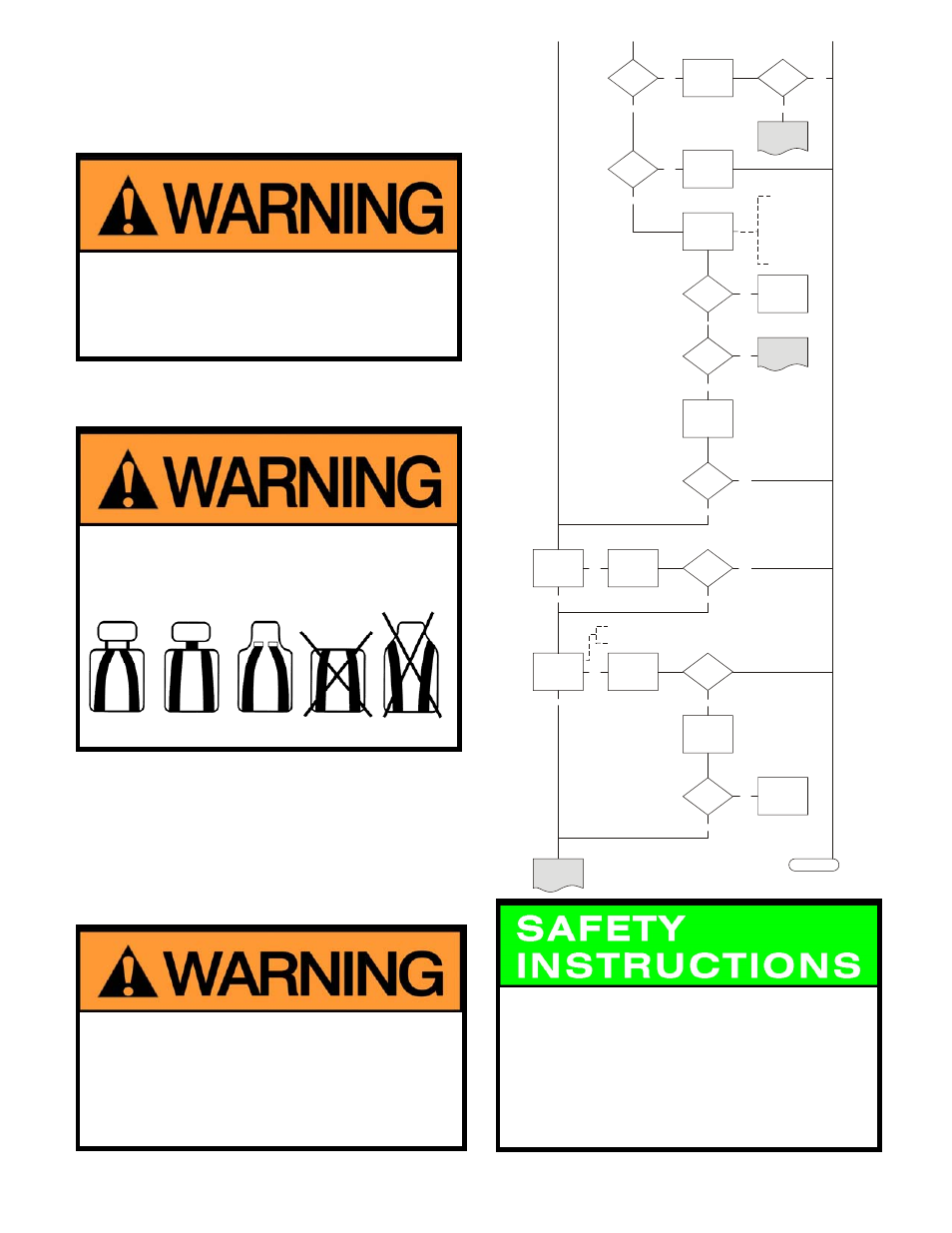

1. Is your vehicle listed in the Certified Vehicle List (Vehicle

Reference List)?

Compare your car’s specifications to the Make, Type No. and

Model Year of vehicle in the Certified Vehicle List (Vehicle

Reference List).

YES NO

Proper harness belt geometry requires that seat belt

anchor points be located within narrowly defined areas.

Therefore SCHROTH harnessbelts may only be installed

in SCHROTH approved vehicles for which proper

anchorage location and belt geometry has been

determined to exist.

2. Are there openings between the backrest and the headrest

of the seat? (See illustration below.)

YES NO

Harness belt system will not function properly and must

not be installed in vehicles equipped with seats having no

headrest or backrests with integrated headrest. (No

openings exist between the backrest and the headrest.)

Never create a new opening in the seats installed in your car.

3. If you intend to install the tail straps of the SCHROTH

harnessbelt system at the rear seat lap belt anchor point

a. have you made sure that the Certified Vehicle List

(Vehicle Reference List) allows or requires you to do so?

YES NO

b. is your vehicle equipped with a SCHROTH approved

seat? (see Certified Vehicle List (Vehicle Reference List)

and Legend on yellow pages)

YES NO

Installation to anchor points located lower than the front

seat backrest with an unapproved seat can result in

serious personal injury or death. Never install the

SCHROTH harnessbelt at these lower anchor points

unless this installation is allowed for your vehicle’s make,

model and model year and it is used with an approved

seat. [See Certified Vehicle List (Vehicle Reference List)

and heed all indexes.]

Page 2

Eye of ground

wire correctly

installed? See

pages 12 and

15.)

Ground

connection OK

between bolt

and chassis?

Replace defective

control wire

(red/black). Use

only SCHROTH

Spare Parts.

Replace defective

control wire

(red/black). Use

only SCHROTH

Spare Parts.

Replace defective

ground wire. Use

only SCHROTH

Spare Parts.

Check testing

points

and .

7

8

Eye properly

located?

Change position

of eye in the

assembly and

remove paint from

the thread.

Test again the

current between

testing point 6

and bolt head.

Ground

connection is

not OK. Please

go back to and

start again.

I

Function

O.K.?

Function

O.K.?

Function

O.K.?

Power at

testing point

?

5

Power at

testing point

?

7

Power at

testing point

?

8

yes

yes

yes

yes

yes

no

yes

yes

no

no

no

no

no

no

Test power between testing point and bolt head.

With a proper connection, the test lamp (voltmeter) will not show voltage.

6

1. Remove rubber

cover (see page 26).

2. Check the wire con-

nection and holder.

3. Power at testing

points and ?

(Positive and

negative terminals.)

7

8

Send retractor

to importer

for inspection.

Send retractor

to importer

for inspection.

no

no

yes

END

a) Make sure plugs

are well connec-

ted to the sensor.

b) Install the sensor

in a permanent

vertical position.

Power at

testing point

?

4

yes

no

Function

O.K.?

yes

no

Send retractor

to importer

for inspection.

Power

measureable?

• The recoil mechanism could remain permanently locked, if

the tail strap is disconnected from the separation buckle

while the ignition is off! The tail strap will be reeled in by

the recoil mechanism. If the latch of the belt hits the cover

without being slowed down, it might cause the recoil

mechanism to permanently lock up.

• If you disconnect the belt from the separation buckle,

make sure that the tail strap is slowly reeled in by manually

slowing the retraction. This will prevent the above-

described effect.

Page 35

right right right wrong wrong