Schroth Racing AutoControl User Manual

Page 19

7.3.1 Current supply wire

• The electrical current supply must be taken from a wire

that does not carry current when the ignition is turned off.

The wire selected must be "live" when the ignition is turned

on, but before the engine starts. The flow of electrical

current must not depend on the operation of any other

electrical system or device.

• We recommend use of the wire feeding the rear window

defogger, or any wire downstream from the fuse box

running from any terminal marked no.15 (non German

manufactured cars may use other symbols, numbers

and/or letters). Do not connect to the wire that powers the

computerized control system in the vehicle.

If the wiring for the harness belt system is connected to a

wire which carries current even when the ignition is off, the

electro-magnetic components of the harness belt system

could draw current continuously and discharge your car’s

battery while parked.

Check the wiring diagram of your vehicle for a suitable lead,

that can be easily used for proper installation as explained

above. If in doubt, please see your car dealer.

If you install two SCHROTH asm-autocontrol harnessbelt

systems in your car, you only have to connect the electrical

system of the left (driver side) retractor directly to a current

supply of the vehicle.

Be sure to follow the wiring instructions for the right (passenger

side) retractor in paragraph 7.3.3 below.

7.3.2 Connecting

To prevent damage to your car’s electrical system, only

make the following connections when the ignition

is turned off.

The fuse wire can be connected at any suitable position to the

current supply wire (from terminal 15 at fuse box in cars of

German manufacture) by the cable connector included.

Page 20

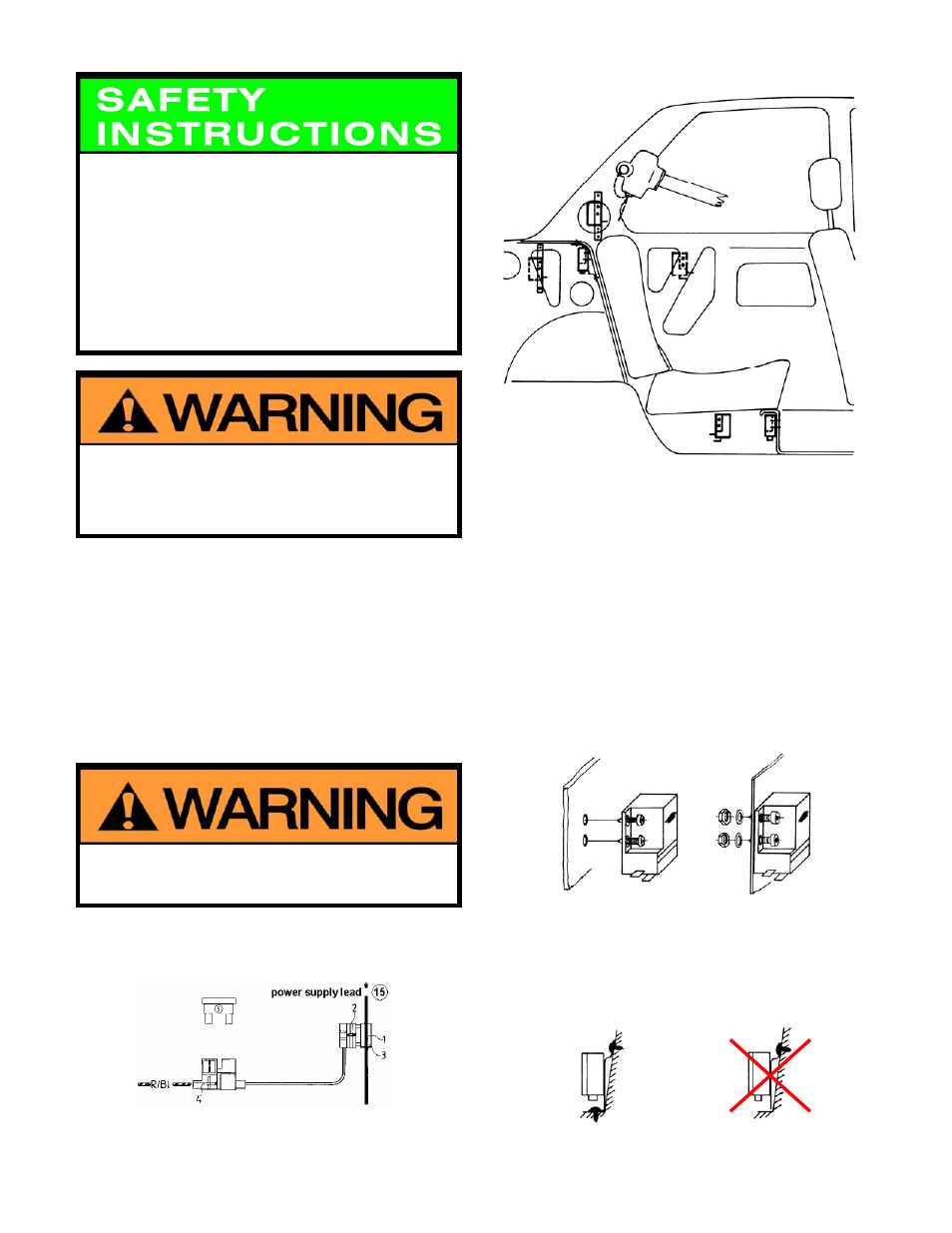

This figure indicates the most suitable positions for the sensor.

The figure shows a car body with interior panels removed.

Only install the sensor directly to a rigid vertical structure of the

car body that does not move.

The mounting holes must be in a straight vertical line and

25

/

32

"

(20 mm) apart. Drill the upper hole first to locate the sensor in

the desired position. Place the bubble level supplied on the top

surface of the sensor to check the front/rear and side-to-side

position. Mark the position for the second hole, drill and

remount the sensor. Recheck the position to make sure the

sensor is leveled.

for self tapping sheet

for 4 mm bolts, drill

metal screws, drill holes

holes

13

/

64

" (5 mm)

5

/

64

" (2 mm).

You can use sensor housing as a stencil.

Installation with the perforated metal strip

The perforated metal strip can be carefully bent and formed as

necessary for vertical installation of the sensor. Make sure that

both ends of the strap are fixed by screws for permanent and

rigid installation of the sensor on a non-moving structure.

right way wrong way

Page 17