S&S Cycle Big Twin Oil Pump Kits User Manual

Page 8

8

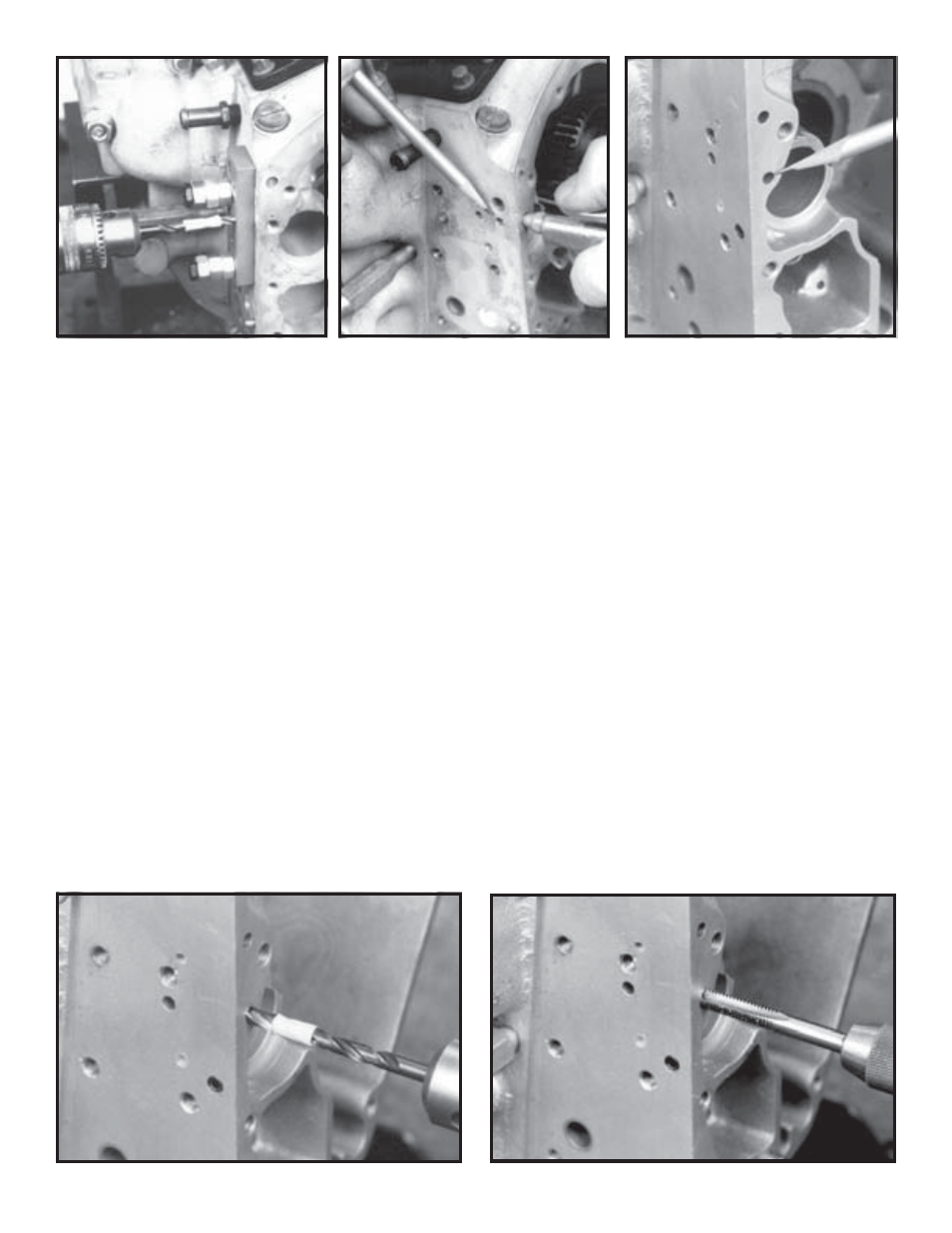

E. Install S&S Oil Pump Drill Jig, part #53-0013,

on crankcase oil pump gasket surface. See

Picture 17.

F. Wrap masking tape around .187" (

3

⁄

16

") drill bit

.750 " (

3

⁄

4

") from drill point to use as depth guide.

Using tape as guide, drill hole into pump gasket

surface .375" (

3

⁄

8

") deep until it breaks into

passageway just tapped. (Hole to be drilled is

3/8" deep and drill jig is

3

⁄

8

" thick -

3

⁄

8

" +

3

⁄

8

" =

3

⁄

4

").

See Picture 17.

NOTE - Do not drill hole too deep. Hole must not extend

into gear cavity side of crankcases.

CAUTION - Improperly drilled oil feed hole may cause

oil to bleed off into gear cavity resulting in oil pressure

loss and possible engine damage.

G. Remove drill jig and blow air into passage to

remove chips. See Picture 18.

CAUTION - Metal filings, dirt and other foreign matter

can cause extensive damage to oil pump and engine.

WARNING - Compressed air and particles dislodged

by compressed air are potentially harmful. Wear

protective goggles when using compressed air and

always direct air stream away from yourself and

others nearby.

5. Optional Crankcase Modification - 1970-1972

only, using #31-6003 cast pump body or #31-6042

billet pump body- Plug and Redrill Crankshaft

Feed Hole

NOTE - Objective of this modification is to alter 1970-

1972 cases to 1973 and later style oiling. With this oiling

system lifters get primary, unrestricted oil pressure first.

Lower end main and rod bearings get secondary, lower-

pressure oil after top end is supplied. This modification is

recommended only if hydraulic lifters are used.

A. Wrap masking tape around .203" (

13

⁄

64

") drill bit

.375" (

3

⁄

8

") from drill point to use as depth guide.

CAREFULLY enlarge hole in Picture 18. Using

tape as guide, drill hole .375" (

3

⁄

8

") deep. See

Pictures 19 and 20.

Picture 21

Picture 20

Picture 17

Picture 19

Picture 18