S&S Cycle Big Twin Oil Pump Kits User Manual

Page 6

6

CAUTION - Improper oil pump installation due to

incorrect identification of crankcase year group may

result in engine damage.

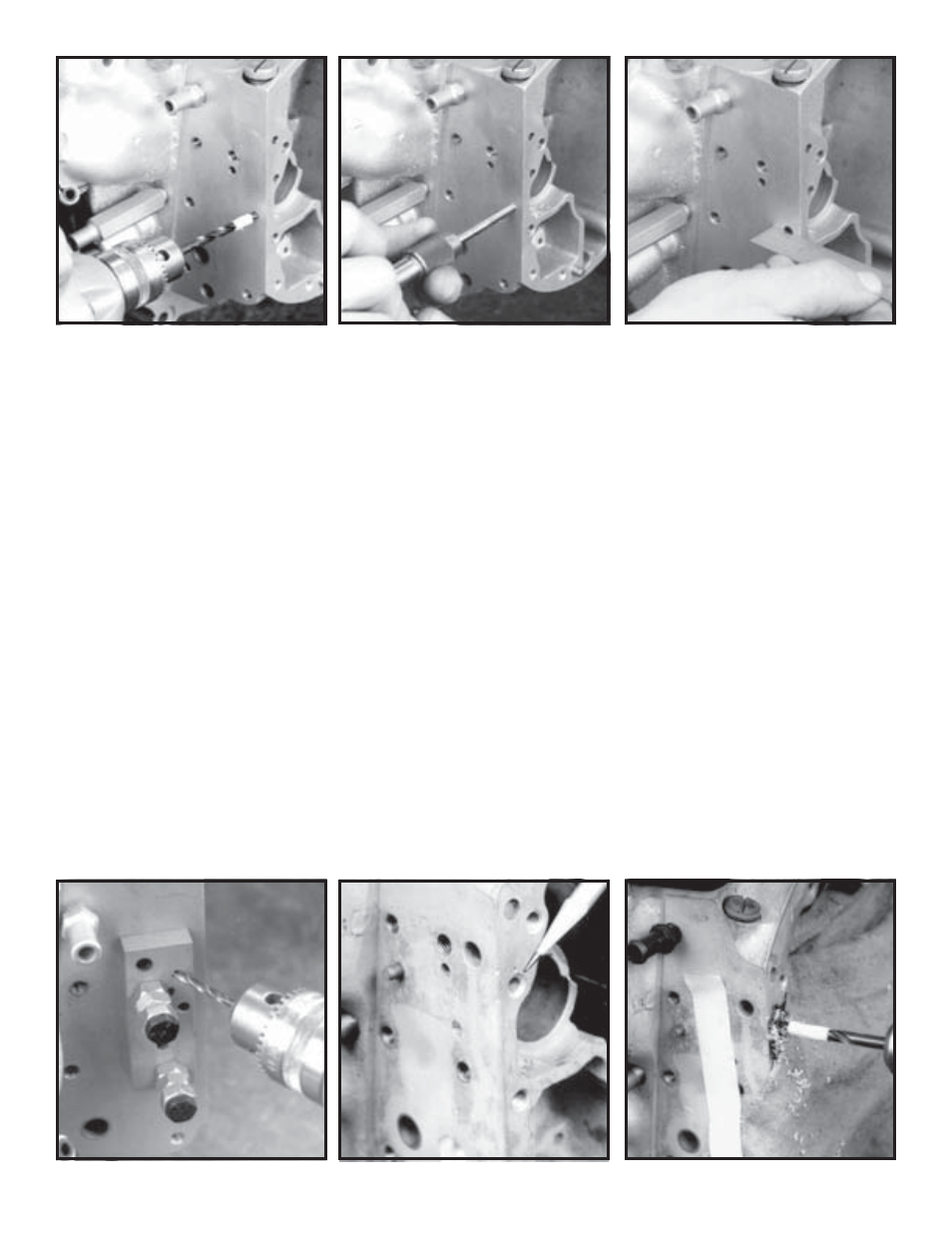

2. Crankcase Modification - 1970-1972 Only

Plug 3/16” Oil Overflow Hole.

A. If engine has been removed from chassis,

CAREFULLY enlarge hole in Picture 8 with .203”

(

13

⁄

64

”) drill. If engine has not been disassembled

apply grease to bit and both ends of hole to catch

chips Wrap masking tape around drill .225” from

drill point to use as depth guide. If engine is in

chassis, enlarging hole may be difficult. In this case

hole may be tapped without enlarging, but extreme

caution is required to avoid breaking tap off in hole.

NOTE - Drill bit outside diameter is very close to hole size

and may tend to distort hole if drill is not steadied.

CAUTION - Distorting hole may cause poor thread fit

after hole is tapped.

B. Using

1

⁄

4

-20 tap, carefully tap hole deep enough

for

1

⁄

4

-20 set screw provided with kit to rest flush

with or slightly below gasket surface. Use straight

edge to confirm set screw does not protrude above

gasket surface. See Pictures 9 and 10. If

necessary, reapply grease to both sides of hole

before inserting

1

⁄

4

-20 tap.

NOTE - Do not tap hole so deep that screw can be

threaded completely through hole. Objective is to have

screw tighten in threads just as it becomes flush with or

slightly below oil pump gasket surface.

C. Install

1

⁄

4

-20 set screw using Loctite on threads.

3. Crankcase Modification - 1970-1980 Only

Drill Pressure Valve Relief Hole.

A. Install S&S Oil Pump Drill Jig, part #53-0013, or

H-D Crankcase Oil Passage Drilling Jig, part

#94461-81 or #94461-82, on oil pump gasket

surface of crankcase.

Picture 11

Picture 13

Picture 12

Picture 8

Picture 10

Picture 9