S&S Cycle Big Twin Oil Pump Kits User Manual

Page 15

15

Oil Pump Installation - All Years

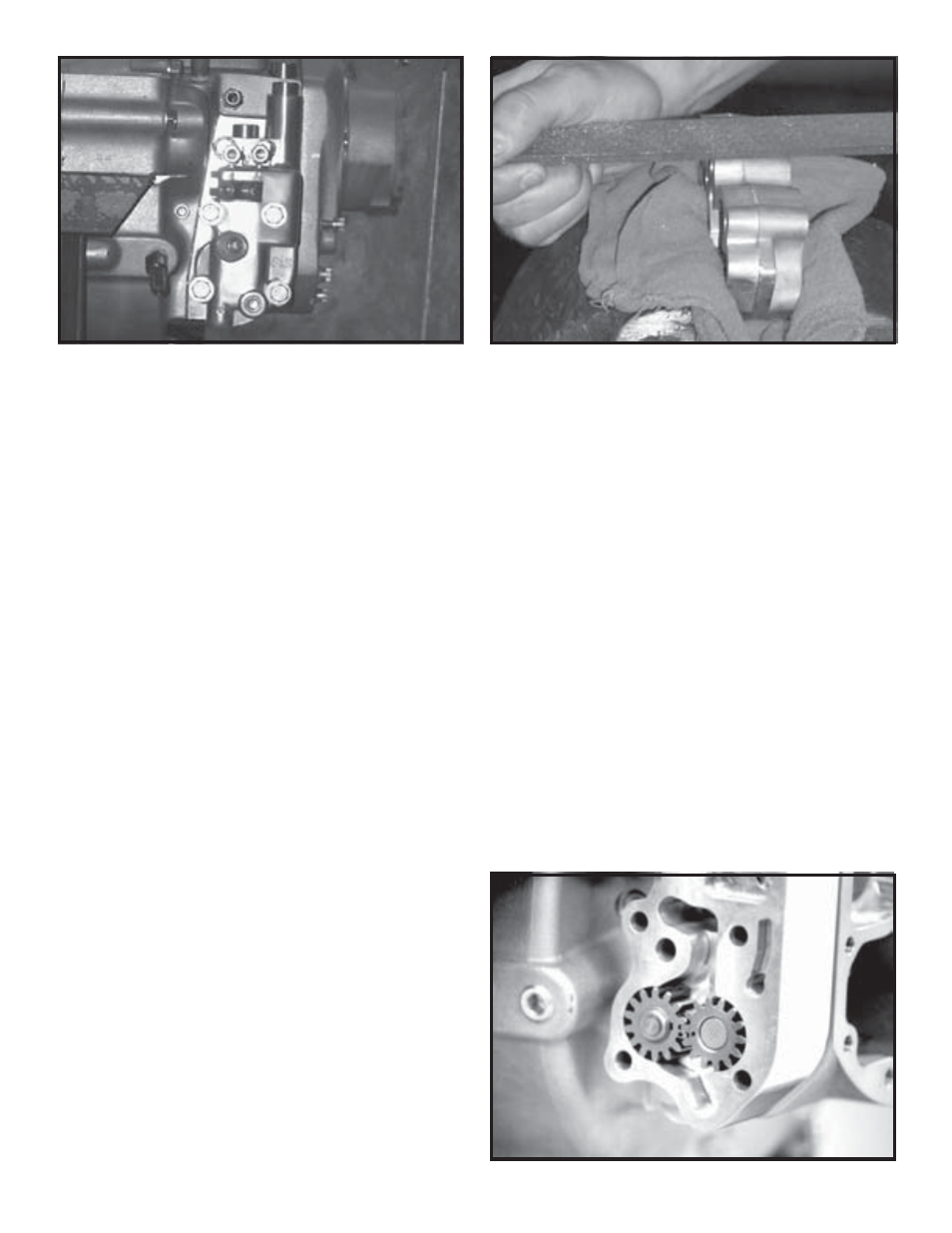

A. Confirm that adequate clearance exists between

oil pump body and crankcase by temporarily

installing pump assembly on crankcase and

inspecting areas indicated in photo. Do not install

oil pump driveshaft gear or snap ring at this time.

See Picture 33. It may prove necessary to

remove a small amount of material from oil pump

body to obtain correct fit. See Picture 34.

NOTES -

●

Remove minimum amount of material required for

proper positioning of oil pump on crankcase. Avoid

damaging gasket surfaces. After modification, clean pump

body thoroughly with suitable parts cleaner solvent and

compressed air to remove metal filings generated during

procedure. Solvent must be of type that will not harm

driveshaft seal in oil pump body. Remove all traces of

solvent prior to installation of pump.

●

1

⁄

4

-24 mounting bolts previously provided with cast oil

pump kits were black. All mounting bolts provided with

current kits are plated. Visually compare threads and

gently screw oil pump mounting bolts into crankcase to

confirm correct thread.

●

S&S oil pump bodies, covers and gaskets may appear

similar to other manifacturerís parts but should not be

interchanged due possible differences in internal

machining, etc.

CAUTIONS -

●

Failure to perform modification described in

Section 8-A correctly may result in oil pump damage

not covered under warranty.

●

Using oil pump components other than those

provided by pump manufacturer may impair overall

function of pump resulting in oil leaks, insufficient

oil pressure and possible engine damage.

WARNINGS -

●

Many solvents are flammable and potentially toxic.

Read solvent manufacturerís instructions prior to use.

●

Compressed air is potentially harmful, especially

to eyes and skin. Wear goggles and other protective

clothing during use, and direct air stream away from

yourself and others nearby.

B. Disassemble, clean, and inspect oil pump, then

reassemble pump dry, without lubrication. (Pump

will be lubricated in final step.)

C. Rotate gears as preliminary check for bind, and

to confirm that drive gear keys are properly

installed.

NOTES -

●

In some instances, oil pump gears have index marks.

To assure proper gear mesh, marks must align when gears

are installed in pump body. See Picture 35.

Marks in photo have been darkened; they normally appear

as light punch marks.

Picture 33

Picture 34

Picture 35