S&S Cycle Big Twin Oil Pump Kits User Manual

Page 16

16

●

If bind occurs, determine whether problem is with

supply or return gears by removing idler gear from either

side and rotating pump. When binding gear is removed,

pump will rotate freely. Problem can usually be corrected

by rotating gear 180

°

.

CAUTION - Failure to correct bind may result in

damage to oil pump or other engine parts.

D. Apply 20W50 engine oil to oil pump driveshaft

and driveshaft bushing in crankcase.

Install oil pump in crankcase in normal fashion,

placing pump drive gear #33-4230 over driveshaft

as shaft is passed through bushing and into

crankcase gear compartment.

NOTE - A dab of Hylomar or other thin gasket sealer in

corners may be used to hold gaskets in place if care is

taken to avoid critical areas such as oil passages and

interior of oil pump. Otherwise gaskets should be

installed dry.

CAUTION - Gasket sealant may interfere with engine

lubrication if allowed to contaminate oil pump or

passages machined in crankcase. Damage related

to improper use of gasket sealant will not be covered

under warranty.

E. Install driveshaft gear key and snap ring,

taking care not to stretch or otherwise damage

snap ring.

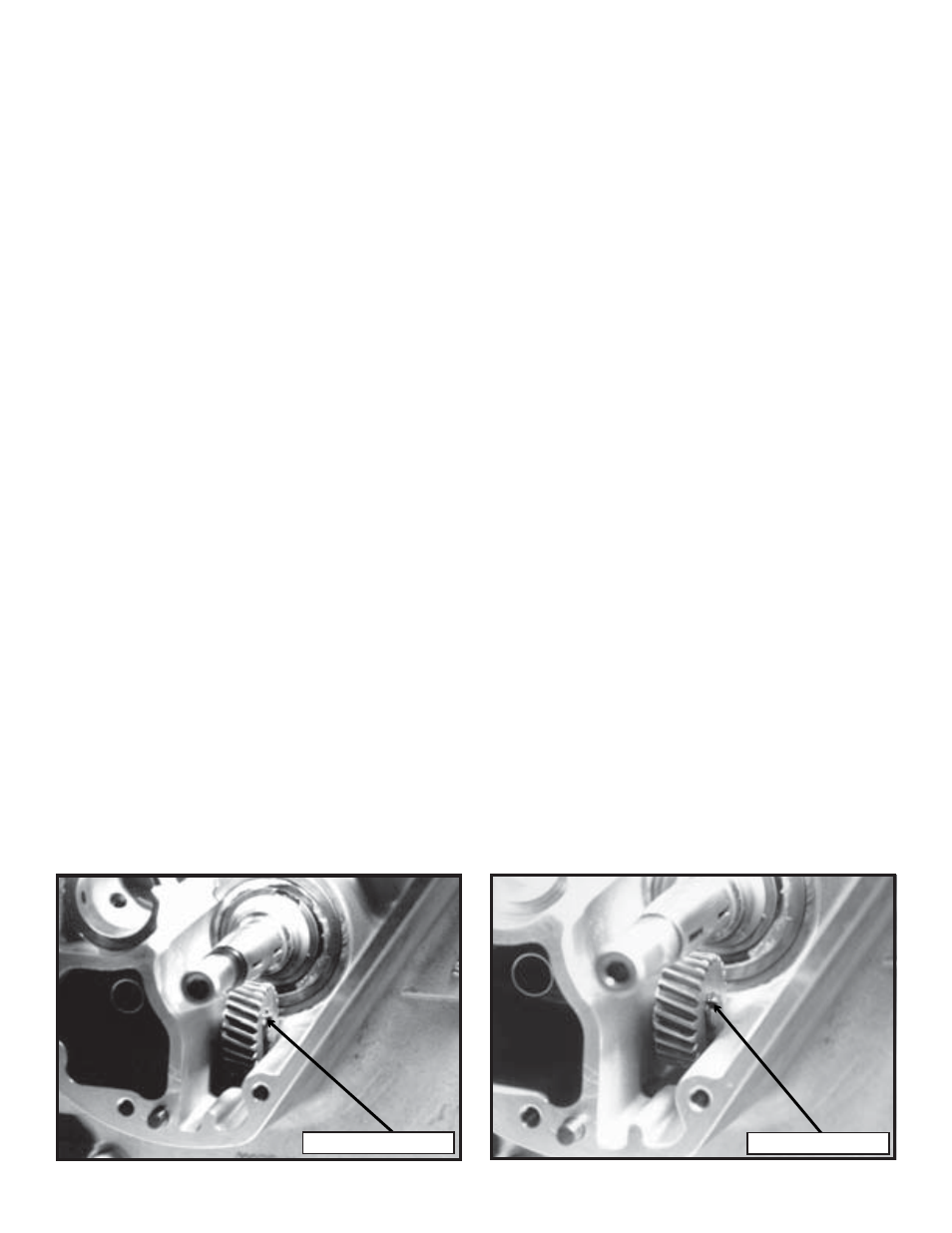

NOTE - Insure that drive shaft key and snap ring are

installed properly. If snap ring is installed incorrectly,

“sprung”, or otherwise damaged, it may become

dislodged or allow gear key to come out. See Pictures

36 and 37.

CAUTION - Loss of oil pump drive gear snap ring or

key will result in disengagement of oil pump causing

loss of oil pressure and extensive engine damage.

F. Loosely install 2 ea.

1

⁄

4

x 1

1

⁄

2

” bolts in upper holes

in oil pump body, followed by pump cover and 4

ea.

1

⁄

4

x 2

3

⁄

4

” mounting bolts. Do not tighten at this

time.

Note -

1

⁄

4

-24 bolts must be used on 1948-1978 H-D

crankcases,

1

⁄

4

-20 bolts on S&S crankcases and later

H-D crankcases. Check thread fit by carefully installing

bolts in crankcase before final assembly. Thread

engagement should be smooth and free of resistance.

CAUTION - Use of incorrect mounting bolts will cause

crankcase damage not covered under warranty.

G. While turning oil pump drive gear to check pump

for binding, gradually tighten 4 ea. 2

3

⁄

4

” bolts in

X-pattern to final spec. of 8-10 ft-lbs. If pump

binds, loosen screws and shift pump slightly

while rotating gears; pump should operate

smoothly if correctly aligned on crankcase.

Retighten bolts while turning driveshaft to

confirm bind-free pump operation. Carefully

tighten two remaining bolts with thin box-end

wrench.

H. Prime pump by removing oil pump check valve

ball assembly and injecting clean motor oil into

pump supply fitting while turning oil pump drive

gear. (A large plastic squeeze bottle works well

for priming pump.) Replace check ball, spring, and

cap after oil fills check valve cavity.

Picture 36

Picture 37

(Correct Installation)

(Incorrect Installation)