S&S Cycle General Flywheel User Manual

Page 7

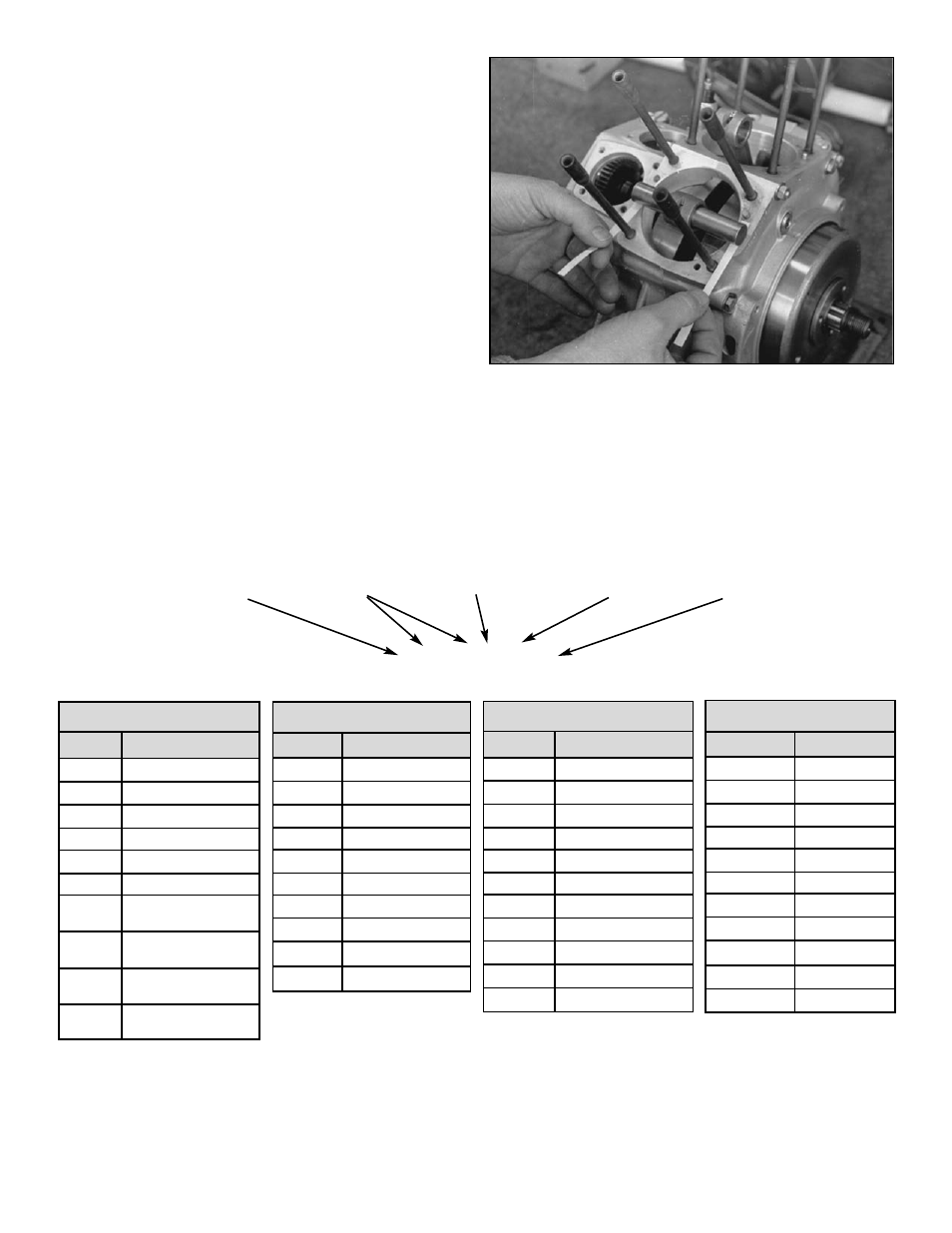

Checking Connecting Rod Straightness

A.

Insert checking pin into wristpin hole. Place strips of paper

between checking pin and crankcase cylinder gasket surface

and apply slight downward pressure to wristpin end of rod

by rotating flywheels. Pull papers out slowly. Drag on papers

should be equal.

B.

Rotate flywheels in opposite direction until checking pin

contacts cylinder gasket surface again. Repeat procedure to

rod again. If drag on papers is equal no bending is required.

If one paper is loose, use rod bending tool to tweak rod in

direction of loose paper and recheck. See Picture 6.

C.

Repeat checking and bending procedure for other rod.

Picture 6

Big twin stroke codes

Code

Stroke

1

4-

3

⁄

8

"

2

4-

1

⁄

2

"

3

4-

3

⁄

8

"

4

5"

5

4-

1

⁄

4

" (Stock 80")

6

4-

5

⁄

8

"

12

5

1

⁄

4

"

13

3-

1

⁄

2

" (Stock 61")

14

3-

31

⁄

32

" (Stock 74")

16

5-

1

⁄

8

"

Four cam stroke codes

Code

Stroke

1

4-

1

⁄

16

"

2

4-

3

⁄

16

"

3

4-

5

⁄

16

"

4

4-

7

⁄

16

"

6

4-

5

⁄

8

"

7

4-

13

⁄

16

"

8

5"

11

4-

1

⁄

2

"

12

5-

1

⁄

4

"

15

3-

13

⁄

16

" (Stock)

16

5-

1

⁄

8

"

Big twin engine style codes

Code

Stroke

E

1936-1954

L

1955-1971

AL

1972-Early 1981

SE*

1955-Early 1981

BL

Late 1981-Up

SL*

Late 1981-Up

J

Early Delkron

4 cam cases

JL

Late Delkron

4 cam cases

H

Early McClure

4 cam cases

HL

Late McClure

4 cam cases

Four cam style codes

Code

Stroke

None

1957-1976

B

1957-Early 1981

SB*

1957-Early 1981

BD†

1977-Early 1981

SBD*†

1977-Early 1981

C

Late 1981-1985

SC*

Late 1981-1985

SCD*†

Late 1981-1985

SCDR*†‡

Late 1981-1985

D§

1986-Up

DRS§†‡

1986-Up

*

Flywheels machined for special S&S sprocket shaft and stock pinion shaft.

§

Flywheels machined for special S&S pinion and sprocket shafts.

†

Flywheel machined to use either 1977 to 1986 style Torrington main bearing or 1987 and later style caged roller pinion shaft main

bearing assembly.

‡

Machined for use with 1986 and later stock xl connecting rod bearings.

FLYWHEEL IDENTIFICATION

Style, stroke, and diameter of S&S

®

flywheels can be determined by examining the serial number which is stamped on the

rim of both flywheels in the set. Usually the flywheel serial number can be read through the timing plug hole of an

assembled engine. Press-together flywheel serial numbers are stamped on the inside rim of S&S flywheels. A cylinder

must be removed in order to read serial number.

Year of

Serial

Flywheel

Engine

Flywheel

Manufacture

Number

Stroke

Style

Diameter

S

S 1

1 2

2 3

3 4

4 -- 3

3 S

S L

L X

X

7