Caution – S&S Cycle General Flywheel User Manual

Page 4

S&S

®

warranty is void if flywheel tapers are lapped.

E.

Check keys in groove of shafts. Keys should be light

hand press fit in grooves. If key is too tight in groove,

sand side key with fine sand paper on a metal plate or

other flat surface. Do not hammer key into groove.

Hammering tight key into groove may result in irreparable

damage to shaft.

F.

With key in shaft, insert into respective tapered hole in

flywheel and check to see that key does not bottom in

groove. If key bottoms out, file flat side of key, not

rounded side, until shaft with key in place fits in

flywheel without bottoming out. Check crankpin and

crankpin key also.

3.

Lower End Assembly

A.

Reclean mainshaft tapers, crankpin and flywheel tapers

with lacquer thinner.

B.

Assemble mainshafts in respective flywheels. Lightly

coat taper and threads of each shaft with green

Loctite

®

during assembly. Install crankpin in camside

flywheel using Loctite

®

also. Refer to table below for

torque specifications.

If stock torque specs are exceeded with stock mainshafts

damage to the mainshaft may result. Flywheels or

connecting rod bearings damaged as a result of blocked oil

passageways that were not checked during assembly are not

covered under warranty.

C.

After camside flywheel, pinion shaft and crankpin are

assembled, blow air through pinion shaft oil feed hole to

check for blockage or misalignment of oil feed passages.

Partially or completely blocked oil feed passageways may

cause irreversible damage to connecting rod bearings and

other engine components.

D.

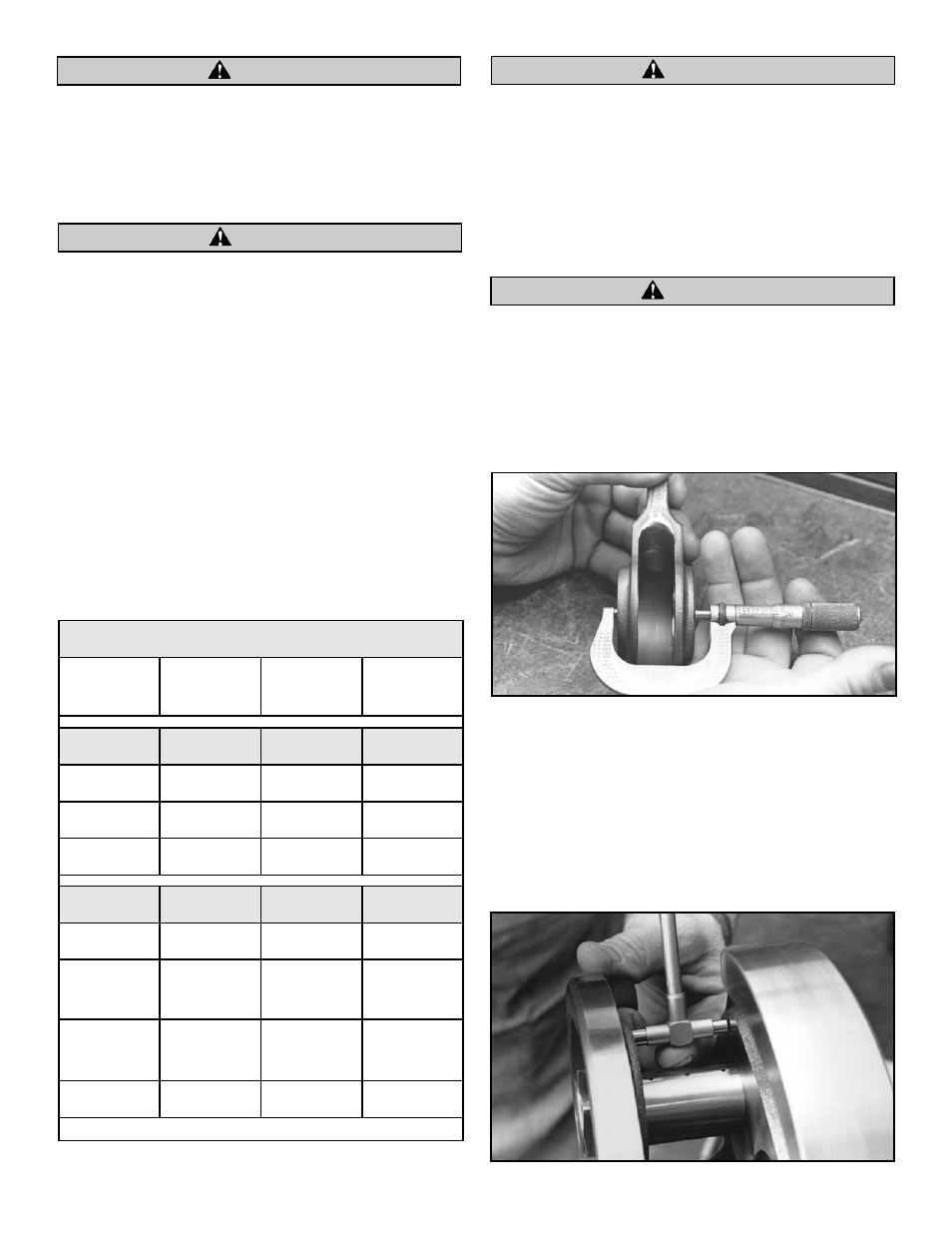

Measure width of female rod on crankpin end. See

Picture 2. Measurement should be 1.743"-1.745" for big

twins, and 1.481"-1.483" for Harley-Davidson

®

Sportster

®

models.

E.

A pre-assembly connecting rod side play check should

be done before final assembly to determine if

connecting rod side play will fall within the specified

.015"-.035" range when crankpin nuts are final

tightened. Assemble left and right flywheels on

crankpin without rods. Moderately snug crankpin nuts.

Do not worry about flywheels being true. Measure

distance between connecting rod thrust pads on

flywheels. See Picture 3.

4

CAUTION

CAUTION

CAUTION

CAUTION

Picture 2

Picture 3

S&S

®

FLYWHEEL ASSEMBLY TORQUE SPECIFICATIONS

Stock Harley-

Davidson

®

Shafts

S&S Shafts

(Street)

S&S Shafts

(Racing)

BIG TWIN

Sprocket Shaft

290-320

400-450

450-0005

Pinion Shaft

140-170

275-300

275-300

Crankpin Nut

180-210

350-400

450-500

SPORTSTER

®

MODEL

Sprocket Shaft

100-120

340-360

350-400

Pinion Shaft -

Pre-1985

Sportster

®

Models

100-120

180-200

200-250

Pinion Shaft -

1985-Up

Sportster

®

Models

100-120

340-360

350-400

Crankpin Nut

150-075

290-310

350-400*

* Using S&S sprocket shaft nut on crankpin.