Caution – S&S Cycle General Flywheel User Manual

Page 5

Rod side play will be reduced by about .015" when

crankpin nut is final tightened. Therefore, distance

between flywheel thrust pads as measured in this check

must be .030"-.050" greater than female rod width

measured in step D. For example, if a big twin female

rod measures 1.744", the distance between flywheel

pads must be 1.774"-1.794". If difference between pad

to pad distance and female rod width is less than .030",

female rod must be surface ground on sides to provide

more clearance. Take equal amounts off each side if

more than .010" is to be removed. If more than .050"

must be removed from female rod width or if difference

between pad to pad distance and female rod width is

greater than .050" a different crankpin should be tried.

If side play is incorrect and different crankpins do not

correct problem, contact S&S

®

.

NOTE: S&S recommended rod side play is .015" to .035". If

material is removed from sides of female rod, overall width of

bearing cages must be reduced so bearings and cages are free to

float with rods without contacting flywheel thrust pads. Bearing

cage side clearance of .008 to .020 less than rod width is

recommended.

●

Incorrect connecting rod side play may cause excessive

rod side thrusting and potential damage to rods,

flywheels and other engine components.

●

Connecting rod bearing and cage assemblies that are

wider than female rod may become damaged upon

contact with flywheel thrust pads. Abrasive particles

from damaged rod bearings may circulate in oil and cause

damage to other engine parts.

J.

Finish assembling flywheels and rods. See S&S Flywheel

Assembly Torque Specification table. Check final

connecting rod side play with feeler gauge.

K.

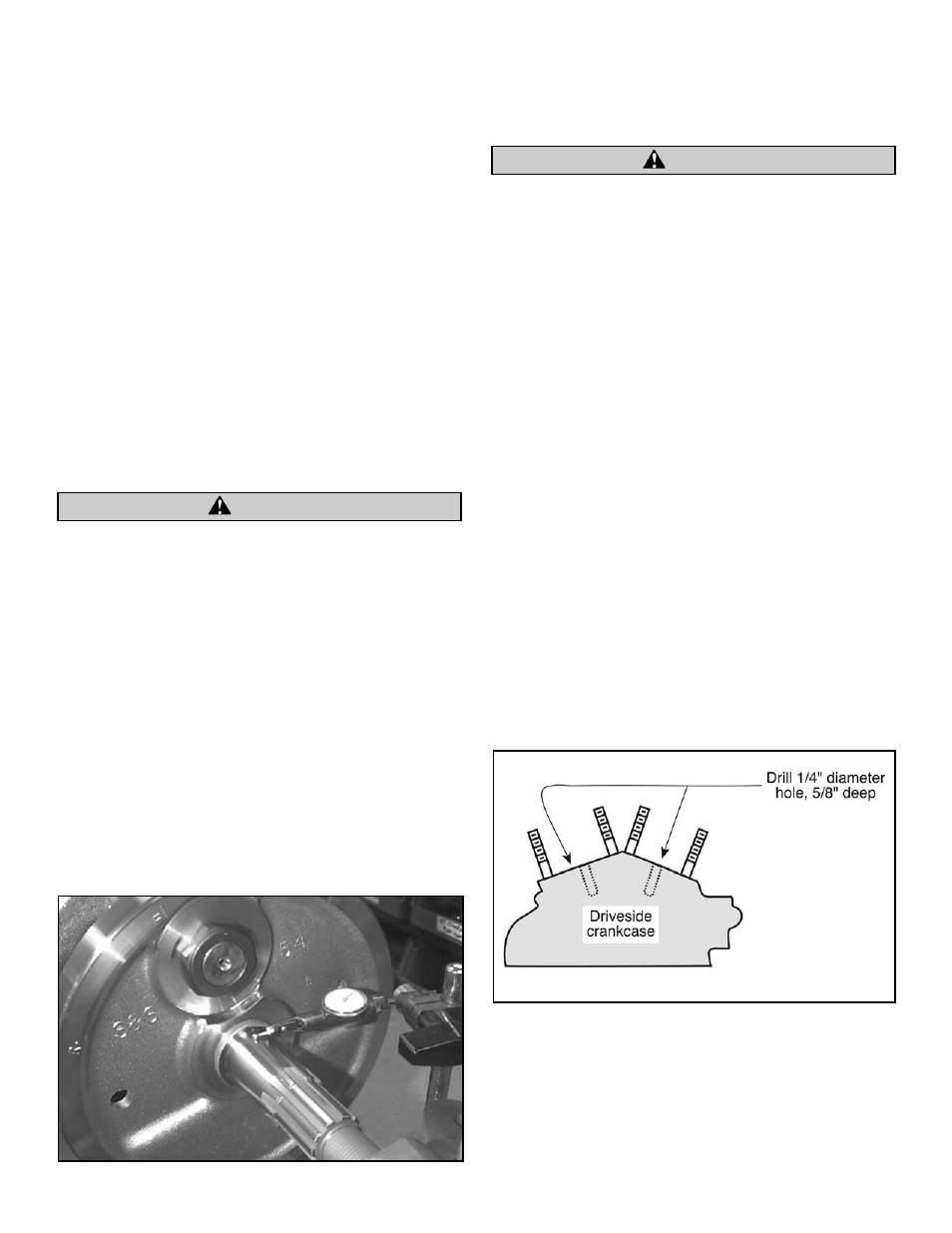

Check flywheel assembly for run out by placing ends of

mainshafts between centers. Place dial indicators on

bearing surfaces of mainshafts. True wheels as needed.

S&S trues flywheel assemblies to .0005" or less runout

on either mainshaft bearing surface. See Picture 4.

NOTE: When truing flywheels, runout measurements must be

taken on mainshaft bearing surfaces. Do not take measurements

on flywheel rims. Flywheel rim will show runout that is not a

valid indication of mainshaft concentricity.

If it is necessary to strike the rim of the flywheels during the

truing procedure, a lead hammer should be used to avoid

damaging the flywheel rim. If rim is dented it may be

impossible to recondition mainshaft tapers due to difficulties

indicating center of taper.

4. Installation

A. For engines of 4

1

⁄

2

" or longer stroke, the oil return holes

in the stock location must be plugged, and the

crankcase must be modified to use the lowered oil

return holes. This modification is necessary due to

increased piston travel in longer stroke engines. Oil

control ring position will be below stock cylinder oil

return hole at the bottom of the stroke. If modification

is not done, oil will be carried to the combustion

chamber by piston rings causing engine to smoke.

NOTE: Engines with strokes shorter then 4

1

⁄

2

" stroke or shorter do

not require this step.

1. If using stock cylinder base gaskets, place base

gasket on cylinder base gasket surface, and punch

1

⁄

4

" hole in gasket directly in center of oil return

hole in base gasket surface of cylinder. S&S gaskets

are pre-punched.

2. Place gasket on driveside crankcase half in its

respective position. Mark crankcase gasket surface

through

1

⁄

4

" diameter hole in gasket.

3. Drill

1

⁄

4

" diameter hole perpendicular into crankcase

gasket surface

5

⁄

8

" deep. See Figure 2.

4. Perform Steps 1 through 3 on other cylinder.

5. Bolt the front and rear cylinders on drive side

crankcase half.

CAUTION

Picture 4

CAUTION

Figure 2

5