Caution – S&S Cycle General Flywheel User Manual

Page 3

ASSEMBLY INSTRUCTIONS

1.

Connecting Rod Preparation (All)

NOTE: If S&S

®

connecting rods are used, follow instructions

that accompany rods since rod preparation below has already

been done.

If S&S rods are not used, perform following steps:

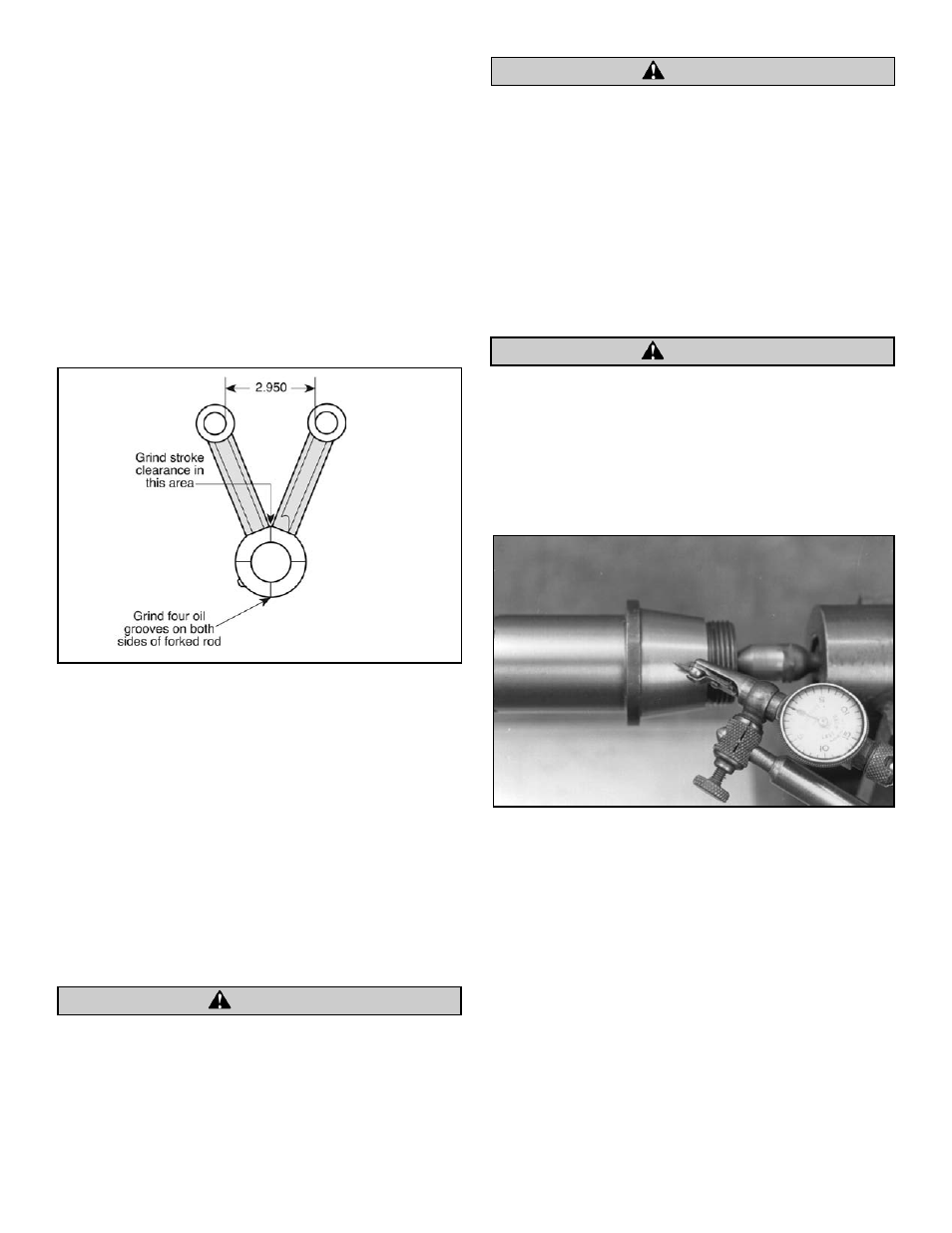

A.

To insure adequate oil on sides of rods and matching

thrust surfaces of flywheels, S&S recommends that four

grooves be ground on each side of both front and rear

connecting rods. See Figure 1. Make these grooves

.020" to .030" deep and .030" to .040" wide and should

be ground 90° from each other. After making grooves,

remove all sharp edges and burrs with emery cloth.

B.

With rods assembled on crankpin and bearings, measure

distance between rods at closest points in wristpin holes.

If measurement as shown in Figure 1 exceeds 2.950" for

rods with .792" wrist pins or 2.850" for rods with .892"

wrist pins, grind female rod at points where male rod

makes contact to achieve sufficient clearance.

NOTES

●

Rods clearanced to this dimension provide adequate

clearance for strokes up to and including 5". Do not

remove any more material than is necessary to obtain

required clearance.

●

Use of .892" diameter wrist pins with stock connecting rods

is not recommended.

Inadequate clearance between rods or too much clearancing

on rods will cause unwarranted stress on connecting rods, rod

bearings, pistons, etc. resulting in possible failure of one or all

aforementioned parts.

C.

Thoroughly clean all parts to remove dirt, filings, etc.

Burrs, dirt, filings, etc. left on connecting rod components may

circulate in oil damaging other parts possibly causing engine failure.

2.

Inspect and Clean All Parts

A.

Flywheel type and style can be determined from

coded information in serial number. Check serial

number of flywheels to insure that flywheels are the

correct type and stroke for application. Refer to

flywheel identification information on page 7.

B.

Thoroughly clean all parts to be used. This includes

mainshafts, main bearings, connecting rods, rod bearings,

keys and flywheels including tapers and key ways.

Burrs, dirt, filings, etc. left on flywheel assembly parts may circulate

in oil damaging other parts possibly causing engine failure.

C.

Check both mainshafts between centers for taper

surface to bearing surface concentricity. Make sure

centers on shafts are clean beforehand. If tapers and

bearing surfaces are concentric with each other and

with center, then truing will be easier. See Picture 1.

NOTE: S&S shafts should not require checking as runout on

ground taper and bearing surfaces on S&S shafts is .0003" or less.

D.

Inspect key ways and oil holes in flywheels for burrs.

Remove burrs if necessary.

NOTE: S&S does not recommend lapping tapers to remove burrs.

This practice tends to distort the taper by removing material

unevenly around the circumference. This makes flywheels

difficult if not impossible to true. In addition the lapping process

work hardens the surface of the taper. The resultant hard surface

makes it very difficult to pull shaft or crankpin into taper. If

crankpin and shafts are not pulled fully into flywheel tapers,

excessive rod side play and assembly width may result. Lapped

flywheel tapers are also very difficult to resurface if repairs are

ever needed.

3

CAUTION

Figure 1

CAUTION

Picture 1

CAUTION