S&S Cycle Lloydz Motorworkz Billet Air Cleaner Kit for Victory Motorcycles User Manual

Page 8

7 – Install the four socket head cap screws up through the intake manifold, throttle body, and throttle body gasket. Thread the four socket head

cap screws in to the backplate, making certain the gasket is captured between the throttle body and the backplate. Hand tighten evenly in a

cross pattern. Once hand tightened finish torque to 72-96 inch pounds.

8 – Locate the pre-formed filter element. Place the filter into the machined groove on the backplate.

9 – Locate the top cover plate. Place the top cover plate on top of the filter element making certain that it fits into the machined groove in to the

top cover plate. Look all the way around the air cleaner assembly and make certain that the filter is positioned evenly into top cover plate and

the backplate.

10 – Locate the supplied Qty 3 - M6 fasteners. Apply 243 Blue Loctite® to the threads and hand tighten evenly into the top cover plate. Finish torque

fasteners to 72-96 inch pounds.

11– Re-secure the wiring harness to its original location on the right side frame rail.

Idle Air Control Bracket, supply and Delivery Hose Installation

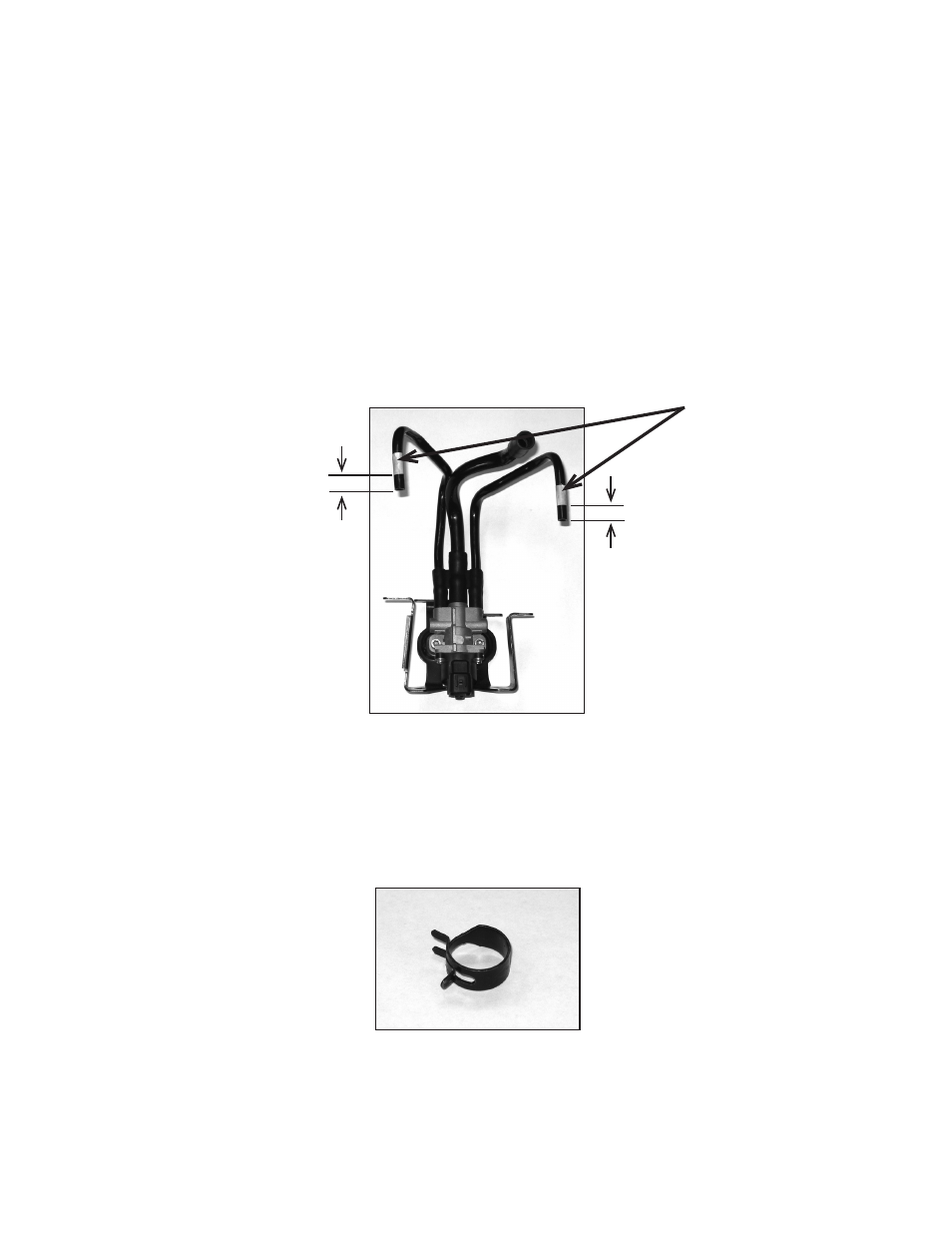

1 – With the Idle Air Control (IAC) bracket, supply and delivery hose assembly on your work bench, measure back .500” from the end of the front

and rear air delivery hoses and mark with a piece of masking tape as illustrated in picture 19 below.

Note: The tape that is placed on the air delivery lines will be your depth gauge for installing lines into the front 90° and rear “T” rubber fittings that

connect to the throttle body. If the air delivery lines are pushed to far into the rubber fittings they may bottom out and restrict air flow causing improper

function of the IAC.

2 – Route the air supply and air delivery lines between the cylinders and to the left side of the motorcycle just as they were routed before

disassembly. Mount the IAC bracket to its original location, to the front and rear heads, on the right side of the motorcycle with the four socket

head cap screws that were removed at disassembly. Tighten fasteners to 85 inch pounds.

3 – Push the front and rear air delivery lines in .500”, or up to the masking tape that was attached in step 1, into the rubber 90° and “T” fittings that

are attached to the throttle body. Once installed remove masking tape.

4 – Locate the black .660” spring clamp, illustrated in picture 20 below, from the supplied hardware pack.

5 – Put the .660” spring clamp over the rubber hose on the air supply line.

6 – Push the rubber piece connected to the air supply line over the brass barb, closest to the throttle body, on the air cleaner.

7 – Move the spring clamp up over the hose barb as illustrated in picture 21 next page.

8 – Reconnect the Throttle Position Sensor to the primary wiring harness at the connector.

picture 19

.500"

.500"

Masking Tape

picture 20

8