S&S Cycle 49-State Certified X-Wedge Engines User Manual

Page 2

2

INSTALLATION OVERVIEW

This S&S® 49-State Certified X-Wedge™ Engine is approved for use in assembled highway motorcycles and conforms to USEPA exhaust emissions

regulations applicable to the model year in which it was produced. A small volume manufacturer, kit manufacturer or assembler using this engine

does not have to apply for a separate emission certificate with the EPA. A vehicle built according to the given requirements is considered a certified

vehicle by the EPA.

Included in these instructions are requirements the manufacturer of the motorcycle, kit manufacturer, or assembler is required to follow in order to

insure the engine meets exhaust and permeation emission standards. Prior to starting installation of this engine these requirements should be read

and understood.

Failure to meet the requirements outlined in the instructions is a violation of the Clean Air Act and will make the manufacturer of the motorcycle, kit

manufacturer, or assembler subject to penalties and fines.

INSTALLATION REqUIREMENTS

No changes may be made to the engine that could reasonably be expected to increase its exhaust emissions for any pollutant. This includes changes

to the fuel metering system; changes to the ignition system; changes to the camshaft; and modifying, recalibrating, removing, or failing to properly

install any other specified component. The following requirements for gear ratio, weight, exhaust, label, and permeation must also be met when

installing this engine.

Gear Ratio

This engine may only be installed in a highway motorcycle or kit with an N/V ratio less than or equal to 44.7. The N/V ratio is the engine RPM divided

by the vehicle speed in miles per hour in high gear. This determines the maximum RPM of the engine for a given vehicle speed in high gear. To find

the N/V ratio for your application divide the engine speed by the vehicle speed while traveling in high gear. The following table gives maximum

RPM’s for the given speed and N/V ratio.

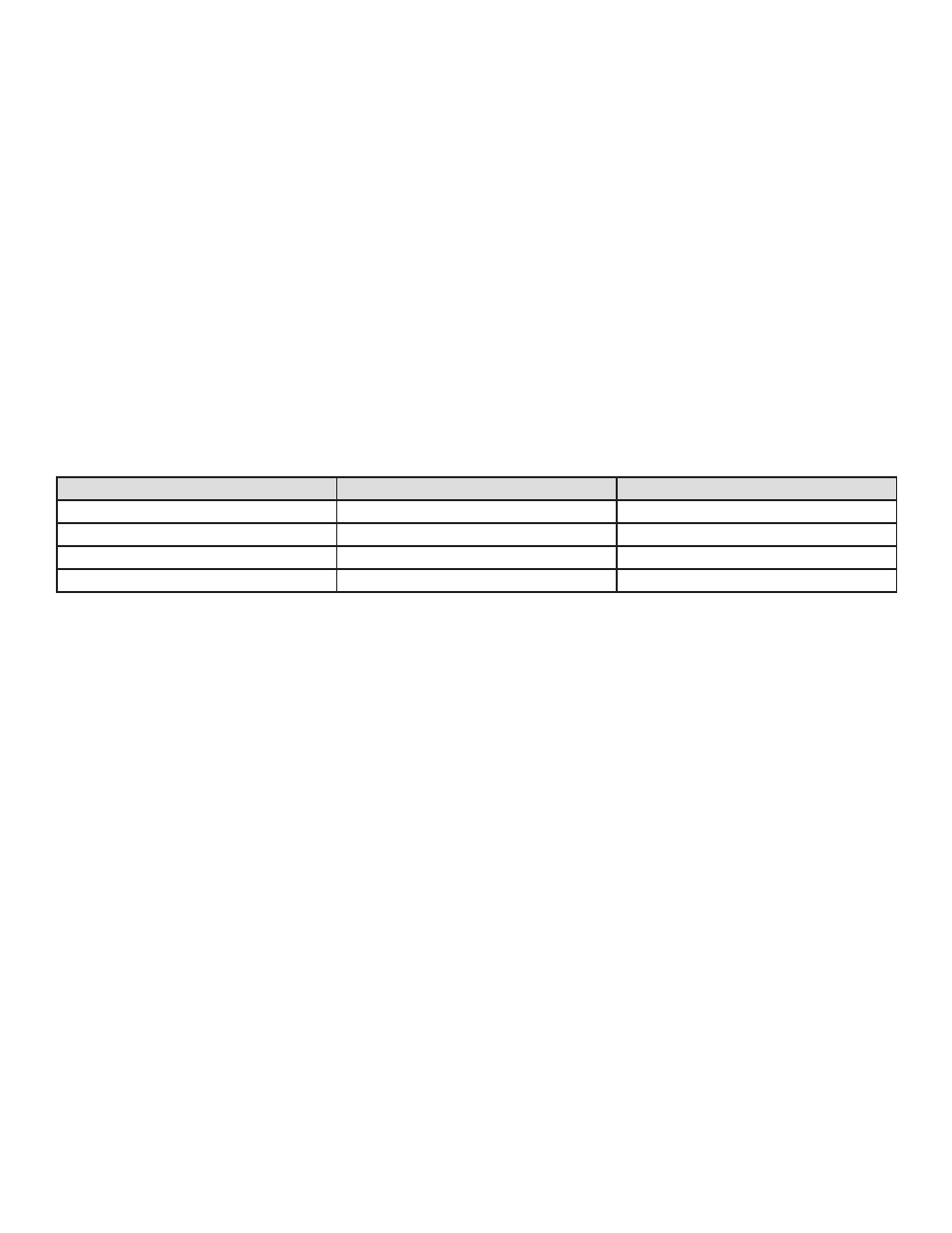

N/V Ratio

Speed (mph)

Maximum RPM

44.7

55

2458

44.7

60

2682

44.7

65

2905

44.7

70

3129

The N/V ratio can also be calculated based on the number of teeth on primary and secondary sprockets, transmission gear ratio in high gear, and

rear tire loaded radius. To calculate the N/V ratio first find the final drive ratio using the following formula:

Primary drive ratio = clutch sprocket teeth/engine sprocket teeth

Secondary ratio = rear sprocket teeth/front sprocket teeth

Transmission ratio = internal gear ratio in top gear

Final drive ratio = (primary ratio) x (secondary ratio) x (transmission ratio)

Next the rear tire circumference must be calculated based on the loaded radius of the tire:

Measure the loaded radius (LR) of the rear wheel by measuring the distance from the ground to the center of the rear axle in inches. This can be

performed with the motorcycle positioned upright on level ground and the rider sitting in a normal riding position. It may be helpful to average the

measurements on both the left and right sides to ensure an accurate number.

Circumference= (6.2832) x (LR)

Next calculate the N/V ratio using the following formula:

N/V ratio= (Final drive ratio x 1056)/(Circumference)

Weight

This engine may only be installed in a highway motorcycle with a final curb mass that is equal to 1,058 lbs or less.

Exhaust

The exhaust system used on the motorcycle must meet backpressure specifications. The total (stagnation) pressure must be in the range of 2.7 to

6.8 inches of water. This measurement is taken 5.5” from the inlet of the front exhaust head pipe with the engine operating at 2000 RPM ±100 RPM

in neutral. The total stagnation pressure can be measured using a pitot tube facing into the exhaust stream and a manometer that reads in inches

of water.

Oxygen sensors for closed loop control must be installed in the exhaust head pipes. The sensors must be located such that they are in the range of

4 to 12 inches from the inlet of the head pipe.