Troubleshooting, Replacing components – RKI Instruments GD-K11D User Manual

Page 22

18 • Maintenance

Model GD-K11D Operator’s Manual

Troubleshooting

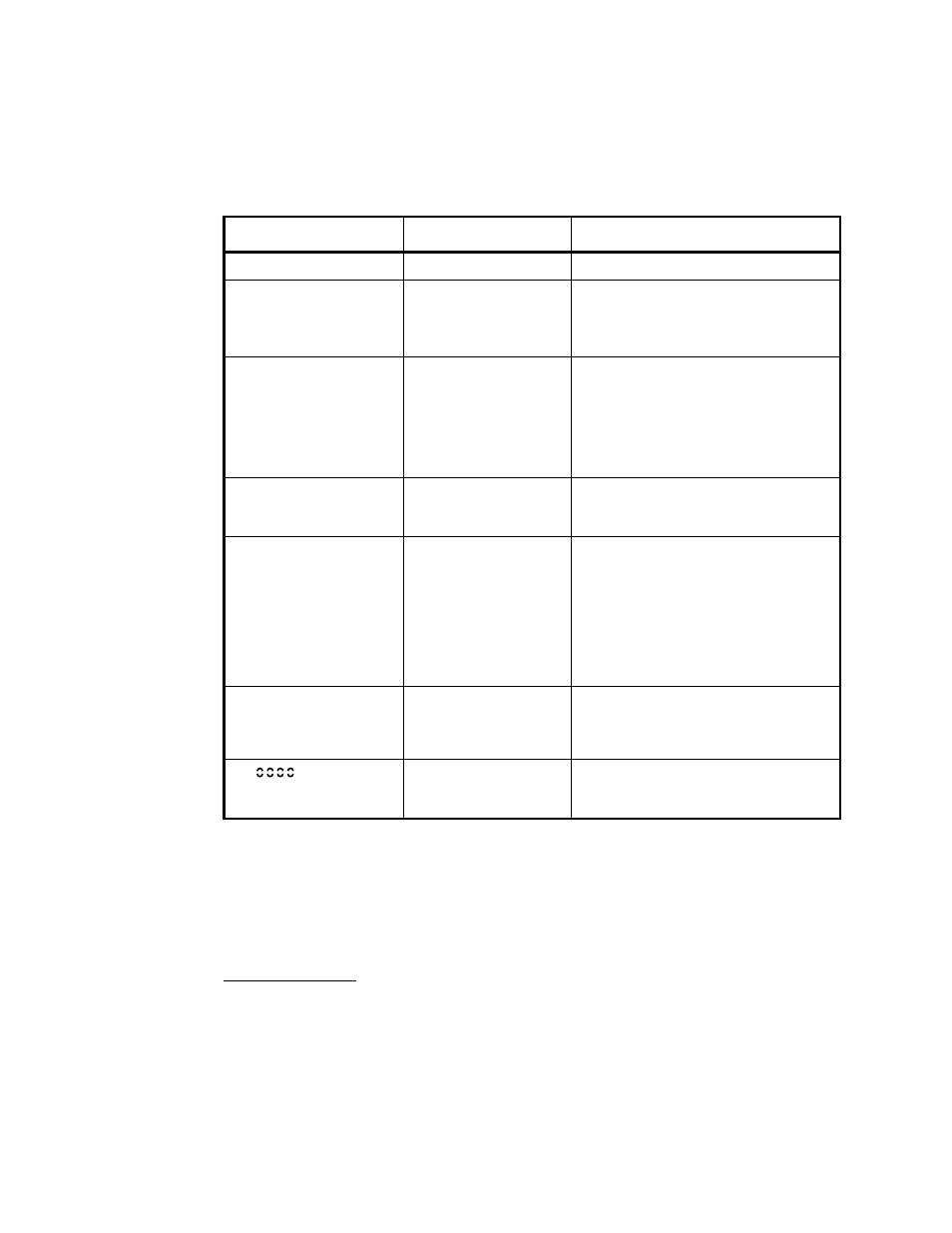

The troubleshooting table describes error messages, symptoms, probable causes, and

recommended action for problems you may encounter with the Model GD-K11D.

Replacing Components

The section includes procedures to replace the sensor, pump, and fuse.

Replacing the sensor

This section includes procedures to remove the sensor, install the replacement sensor,

enter the new K number, and set the zero reading.

Removing the sensor

1. Loosen the thumbscrew at the top of the housing.

2. Rotate the housing cover toward the bottom of the housing to gain access to the

interior of the Model GD-K11D.

3. Place the power switch in the OFF position.

Table 8: Troubleshooting the Model GD-K11D

Symptoms

Probable Causes

Recommended Action

•

E-00 on display screen

•

Memory error

1. Contact RKI Instruments, Inc.

•

E-01 on display screen

•

PW/TR light is flashing

•

Output is 0.5 mA

•

Sensor is disconnected

1. Verify that the sensor connector is

securely connected to the sensor.

2. Calibrate the sensor.

3. If difficulties continue, contact RKI.

•

E-05 on display screen

•

PW/TR light is flashing

•

Output is 0.5 mA

•

Low flow light is on

•

Flowmeter indicates low

flow rate

•

Sample line is

obstructed

•

Pump is disconnected

•

Pump is failing

1. Set the correct flow rate with the flow

adjust valve.

2. Check the sample line for obstructions or

kinks.

3. Verify that the pump connector is

plugged into the pump socket (PUMP).

4. If difficulties continue, contact RKI.

•

E-06 on display screen

•

Communication error

1. Verify that wiring to the 4-20mA output

terminales is correct.

2. If difficulties continue, contact RKI.

•

Unable to zero or span

reading during

calibration

•

Calibration cylinder is

low, out-dated, or

defective

•

Sample line is

obstructed

1. Verify that the calibration cylinder

contains an adequate supply of a fresh

calibration sample.

2. If necessary, set the correct flow rate with

the flow adjust valve.

3. If you cannot set the correct flow rate,

check the calibration tubing for

obstructions or kinks.

4. If difficulties continue, contact RKI.

•

Display screen does not

indicate gas reading

•

Model GD-K11D is in

maintenance mode

1. Verify that the INT switch is in the “0”

position. Adjust the switch if necessary.

2. Press the MODE button until the normal

screen appears.

•

on display screen

•

Abnormal indication

•

LCD (display) not

working

1. Set the sensor’s zero reading as described

on page 11.

2. If difficulties continue, contact RKI.