Retsch PP 25 User Manual

Page 19

Operating the machine

19

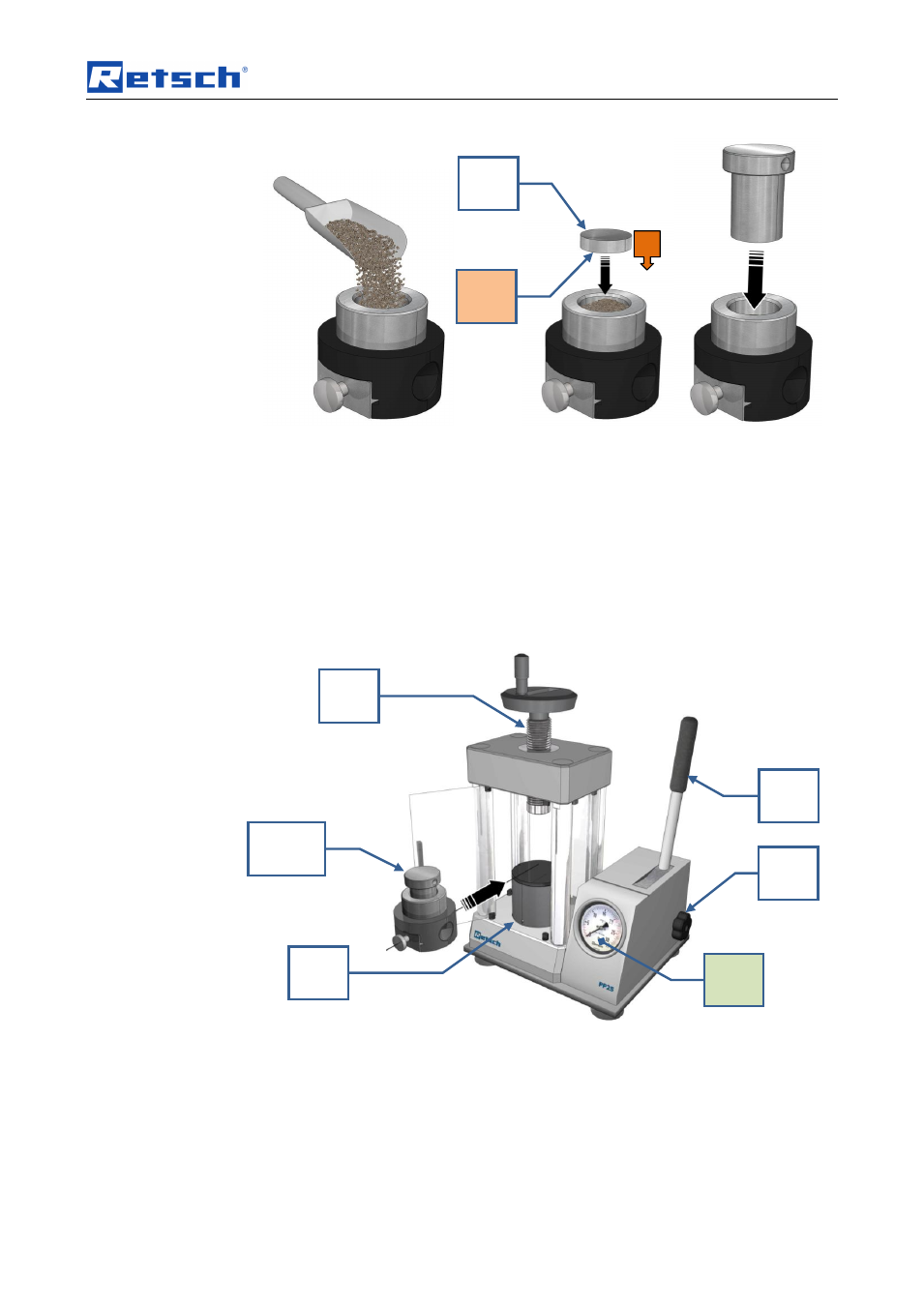

Fig. 3: Filling in the sample

•

Fill the sample material into the die tool (approx. 15 grams).

The pressure pieces are ground and polished on one side.

•

Insert the second pressure piece (N) with the ground and polished side (T)

facing downwards.

•

Insert the plunger (M) into the die tool.

Press the plunger (M) downwards so that the air cushion escapes.

5.5.3

Pressing the tablet

Fig. 4: Inserting the die tool

NOTE

Damage to the seals and constant loss of pressure

A constant build-up of pressure while the cylinder (J) is moved out to the full extent

damages the seals. There is a fine groove on the cylinder. This groove should not

be visible while the pressure is building up.

T

D

PW

J

H

B

t

N

See also other documents in the category Retsch Equipment:

- BB 50 (41 pages)

- BB 100 (24 pages)

- BB 200 (24 pages)

- BB 300 (24 pages)

- Cryomill (68 pages)

- CryoMill Autofill 50l (28 pages)

- DM 200 (20 pages)

- DM 400 (60 pages)

- Emax (67 pages)

- GM 200 (44 pages)

- GM 300 (44 pages)

- MM 200 (32 pages)

- MM 400 (32 pages)

- PM 100 (44 pages)

- PM 400 (36 pages)

- PM GrindControl (48 pages)

- RM 200 (36 pages)

- RS 200 (32 pages)

- SK 100 (24 pages)

- SM 100 (48 pages)

- SM 200 (48 pages)

- SM 300 (44 pages)

- Cyclone - SM 300 (20 pages)

- SR 200 (24 pages)

- SR 300 (24 pages)

- TWISTER (44 pages)

- ZM 200 (32 pages)

- AS 200 jet - Automatic Vacuum Regulation (6 pages)

- AS 200 control - natural frequency (32 pages)

- AS 200 (36 pages)

- AS 200 jet (56 pages)

- AS 200 jet (48 pages)

- AS 200 tap 30.025.0001 (28 pages)

- AS 200 tap 30.025.1001 (28 pages)

- AS 300 (32 pages)

- AS 400 (32 pages)

- AS 400 (28 pages)

- AS 450 basic (40 pages)

- AS 450 basic (44 pages)

- AS 450 control (52 pages)

- DR 100 (40 pages)

- DR 100 (28 pages)

- PP 40 (28 pages)

- PT 100 (36 pages)