Retsch PM 200 User Manual

Page 17

Retsch GmbH

17

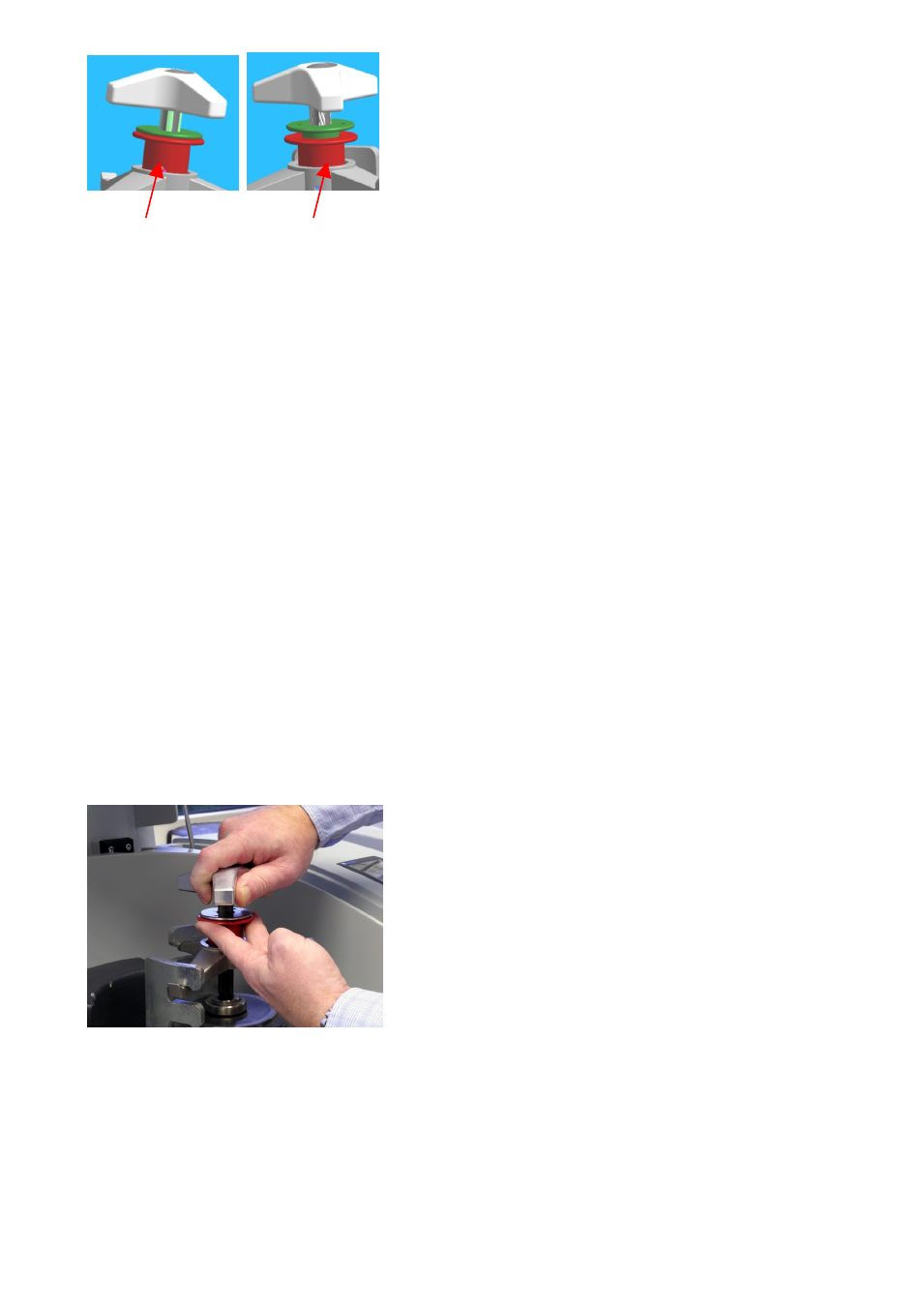

5 Up = free

5 Down = locked

Clean the grinding bowl disk with torsion lock pin 1

Turn the label on the grinding bowl 2 to the same side as

the torsion lock pin, the borehole in the grinding bowl is

located here.

Insert the grinding bowl into the grinding bowl fixture

Pay attention to the torsion lock in 250 and 500 ml grinding

bowls. The borehole in the base of the grinding bowl to take

up the torsion lock pin is located on the side of the marking

areas.

Insert grinding bowl clamping arrangement 3 into latching

brackets 4

Pull red sleeve 5 upwards and clamp the grinding bowl by

turning the three-point grip to the right

Let red sleeve 5 latch audibly downwards, if necessary,

retighten gently from the three-point grip

The three-point grip should now not be able to be turned

Should the red locking sleeve not move completely

downwards when released (audible clacking), briefly retighten

from the three-point grip.

The red locking sleeve, which is now in the locked position,

prevents the threaded spindle from working loose.

Removing the grinding bowl fastening device in the PM100

Pull the red sleeve 5 upwards and unscrew the

grinding bowl by turning the three star grip to the

left.

Continue to turn the three star grip to the left until

the grinding bowl fastening device can be removed.

Tightening and unscrewing the grinding bowl

fastening device using a counter spanner

Using a counter spanner prevents the drive from turning, which can otherwise easily occur when

tightening or loosening the grinding bowl.