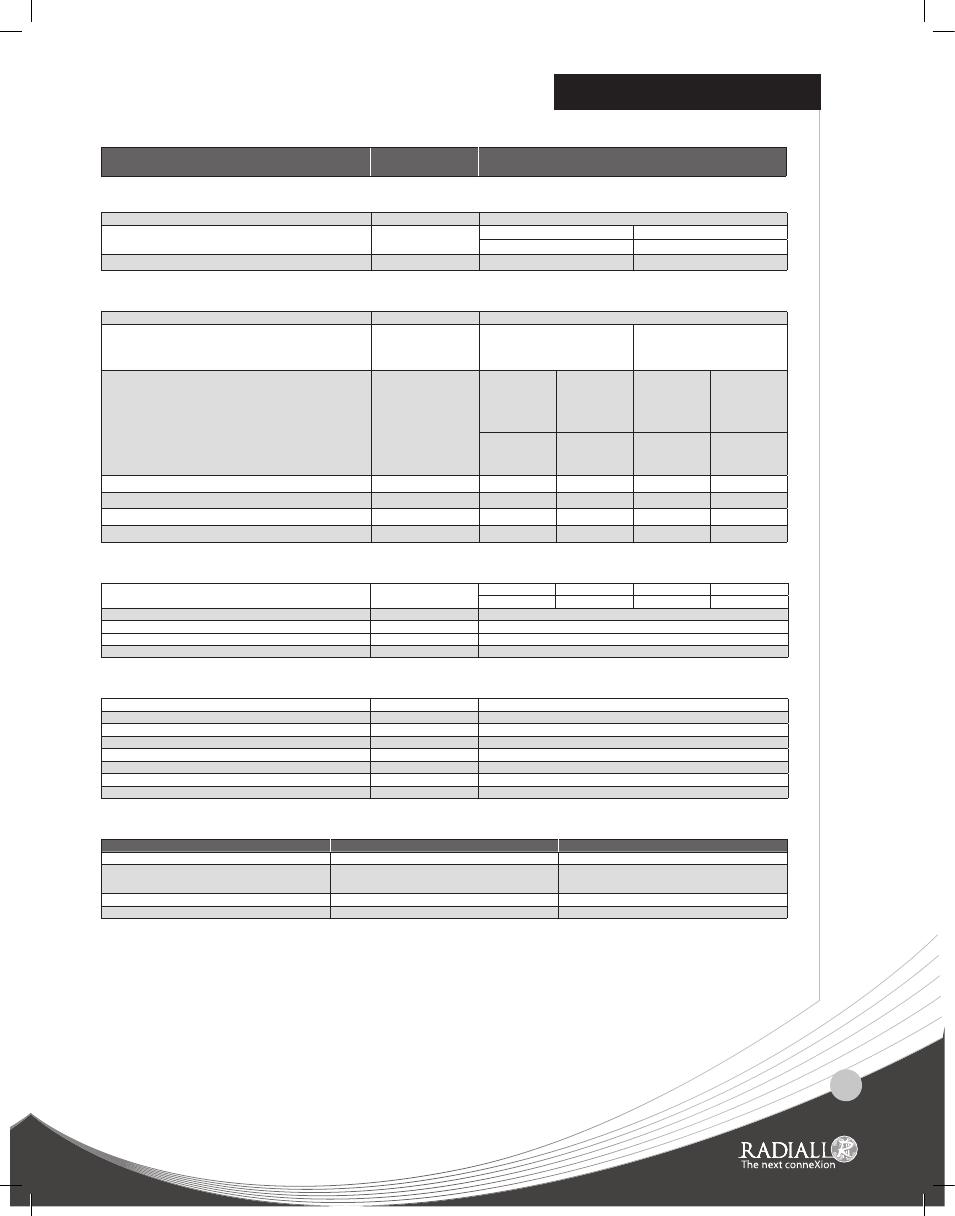

Characteristics, Sma- com, Characteristics general – Northern Connectors Radiall SMA Series Coaxial Connectors User Manual

Page 35: Electrical characteristics, Mechanical characteristics, Environmental characteristics, Materials and plating

www.radiall.com

8-35

SMA-

COM

CHaRaCTERISTICS

gENERal

Impedance

50Ω

Frequency range

Semi-rigid cables

Standard models

DC - 18 GHz

DC - 12.4 GHz

Temperature range

- 65°C + 105°C

- 65°C + 165°C

ElECTRICal CHaRaCTERISTICS

Insulation resistance

3-11

5 000 MΩ mini.

Contact resistance

• Outer conductor

• Inner conductor

3-16

Initial

3 mΩ

2 mΩ

After test

4 mΩ

3 mΩ

V.S.W.R. max up to:

18 ghz for semi-rigid cable

12.4 ghz for right angle connector (Sr)

12.4 ghz for flexible cable

3-14

.085"

.141"

2.6/50/S

5/50/D

• Straight Connector

• Right angle connector

1.07 + .01F

1.10 + .01F

1.05 + .01F

1.10 + .01F

1.15 + .02F

1.15 + .03F

1.15 + .01F

1.15 + .02F

Dielectric withstanding voltage in VRMS

3-17

750

1000

750

1000

Working voltage in VRMS (sea level)

335

500

250

335

Working voltage in VRMS (70 000 ft)

85

125

65

85

RF testing voltage at 5 MHz in VRMS

3-23

500

670

500

670

MECHaNICal CHaRaCTERISTICS

Cable retention force

3-24

.085"

.141"

2.6/50/S

5/50/d

130 N

270 N

90 N

204 N

Life

3-15

100 matings

Force to engage and disengage

3-5-1

23 Ncm - 2 inch pounds

Coupling nut torque recommended

60 Ncm - 5.2 inch pounds

Coupling nut retention force

3-25

272 N min

ENVIRONMENTal CHaRaCTERISTICS

Vibration

3-18

MIL STD 202, method 204, condition D,20g

Shock

3-19

MIL STD 202, method 213, condition I,100g

Thermal shock

3-20

MIL STD 202, method 107, condition B,

Corrosion (salt spray)

3-13

MIL STD 202, method 101, condition B,

Moisture resistance

3-21

MIL STD 202, method 106

Barometric pressure

3-22

MIL STD 202, method 105, condition C

Hermetic test

Down to 10

-6

mmHg (Torr) leakage rate < 10

-8

atm/cm

3

/sec

Life (at high temperature)

MIL STD 202, method 108

MaTERIalS aND PlaTINg

Material

Plating

Bodies

Brass

BBR* or Gold plated

Center contacts

Beryllium copper (female)

Brass (male)

Gold plated

Insulators

PTFE teflon

Gaskets

Silicone rubber

All dimensions are given in mm

Test/characteristics

MIL-C-39012

paragraph

Values/remarks

Standard packaging: 100 pieces.

*BBR: Bright Bronze Radiall