Maintenance, Realignment method 1 – Multiquip TP24X User Manual

Page 28

page 28 — Tp24X TILe SaW • operaTIon and parTS manuaL — rev. #2 (04/12/12)

reaLIgnmenT

method 1

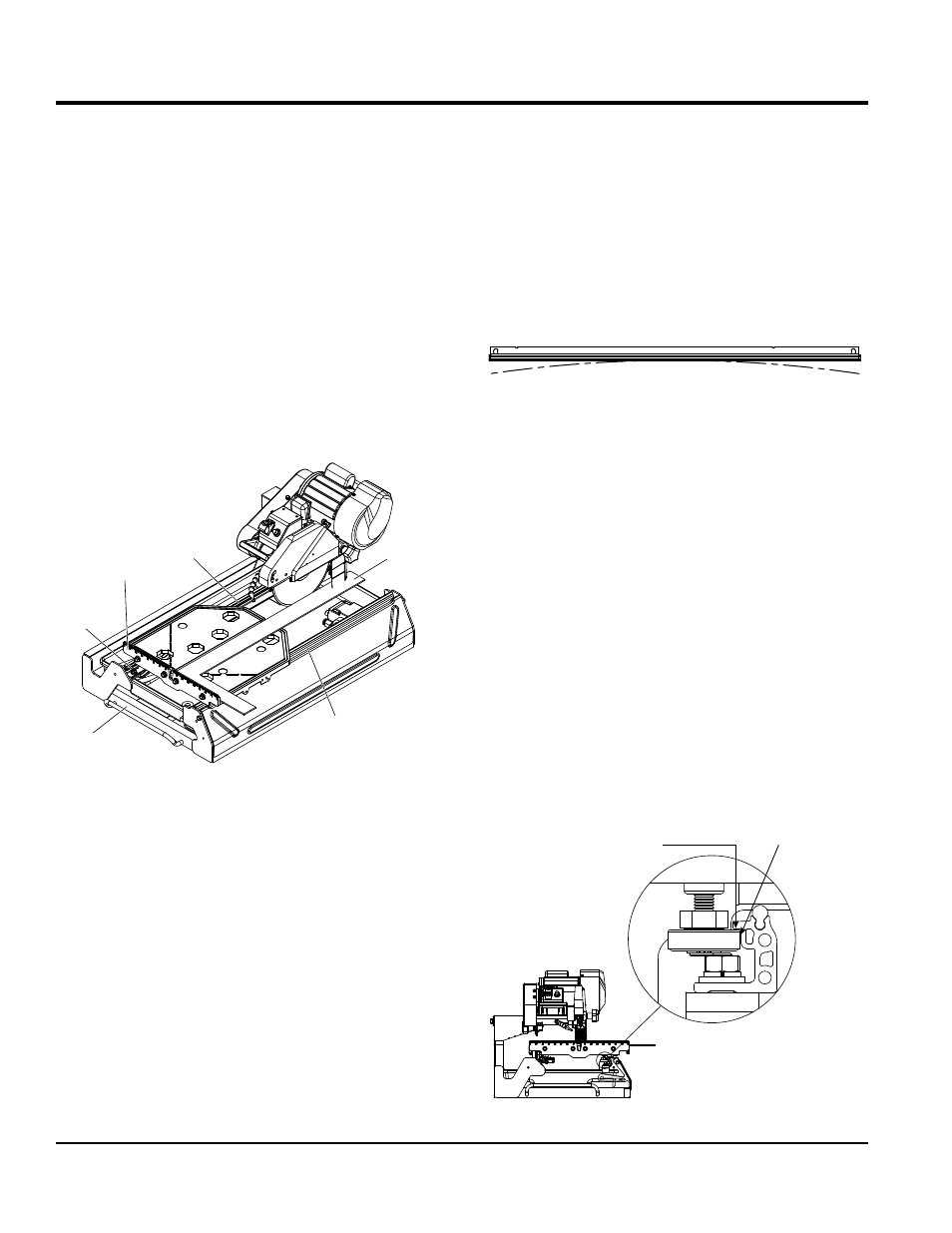

This procedure deals with the most common source of

misalignment that occurs when the guide rails are not

parallel with the blade.

1. Set the cutting depth such that the blade passes

through the table, not over.

2. Place a straight edge (i.e. carpenter’s square) on the

cutting table as shown in Figure 22.

3. Loosen the left and right guide rails by loosening the

fasteners found at the ends of the rail. The left rail

should be slightly loose, so there is not too much play

during adjustments, but the right rail should move freely.

Figure 22. Realigning Guide Rails

4. Make sure the short portion of the straight edge is placed

flush against the ruler guide. Adjust the left guide rail

so that the front and rear edges of the blade touch the

straight edge, although a tolerance of 0.1mm (.004 in.)

between the front and rear edges is allowed. Perform this

adjustment along the entire length of the straight edge.

5. Position the table as close to the user as possible. Place

the straight edge flush against the ruler guide and blade.

Without holding onto the straight edge, gently move

the table towards the rear of the saw and then back.

Observe any gaps that may appear between the straight

edge and blade or between the straight edge and ruler

guide. A gap exceeding the allowed tolerance means

that the table is not moving parallel to the blade; hence,

FASTENER

RULER

GUIDE

STRAIGHT

EDGE

RIGHT

GUIDE

RAIL

LEFT

GUIDE

RAIL

FRONT

OF THE

SAW

further adjustments as outlined below will be required.

However, if scenario A or B (described below) occurs,

other adjustments may be required instead.

a. If the straight edge only touches the blade when

the table is positioned midway along the rail or at

the ends of the rail, then the rail may be deformed

(i.e. bowed). See Figure 23. Perform test cuts to

determine if the rail should be replaced. Typically,

a bowing displacement of up to 0.2mm (.008 in.)

will not affect cutting accuracy.

Figure 23. Rail Deformation

b. If the straight edge touches both edges of the blade

intially, but shifts apart as the table travels along

the rail, proceed to Method 2.

6. Tighten the fasteners at both ends of the left rail.

7. Adjust the right guide rail so that the horizontal rollers

underneath the table engage the rail as shown in

Figure 24. In most cases the rollers will not have to

be vertically adjusted. Spacing between rails must

be equidistant at all points to ensure that they are

parallel. Once adjustments are made, lightly tighten

the fasteners on the right rail and move the table back

and forth. If the table binds against the rail at any

point, adjust spacing accordingly until the table moves

smoothly.

8. Tighten the fasteners at both ends of the right rail.

If alignment has been achieved, do not proceed to Method 2.

Figure 24. Adjust Right Guide Rail

LEAVE HAIRLINE GAP

BETWEEN RAIL AND ROLLER

LEAVE A 1/32 IN.

(1MM) GAP

Maintenance