Hpha36c5h trowel — maintenance – Multiquip HPHA36C5H User Manual

Page 31

HPHA36C5H WALK-BEHIND TROWEL — OPERATION AND PARTS MANUAL — REV. #3 (07/06/10) — PAGE 31

HPHA36C5H TROWEL — MAINTENANCE

■ Does the trowel have a perceived rolling or bouncing

motion when in use?

■ Look at the trowel while it is running, does the guard

ring “rock up and down” relative to the ground?

2. Start engine, and bring trowel blades up to full speed and look

for the following conditions:

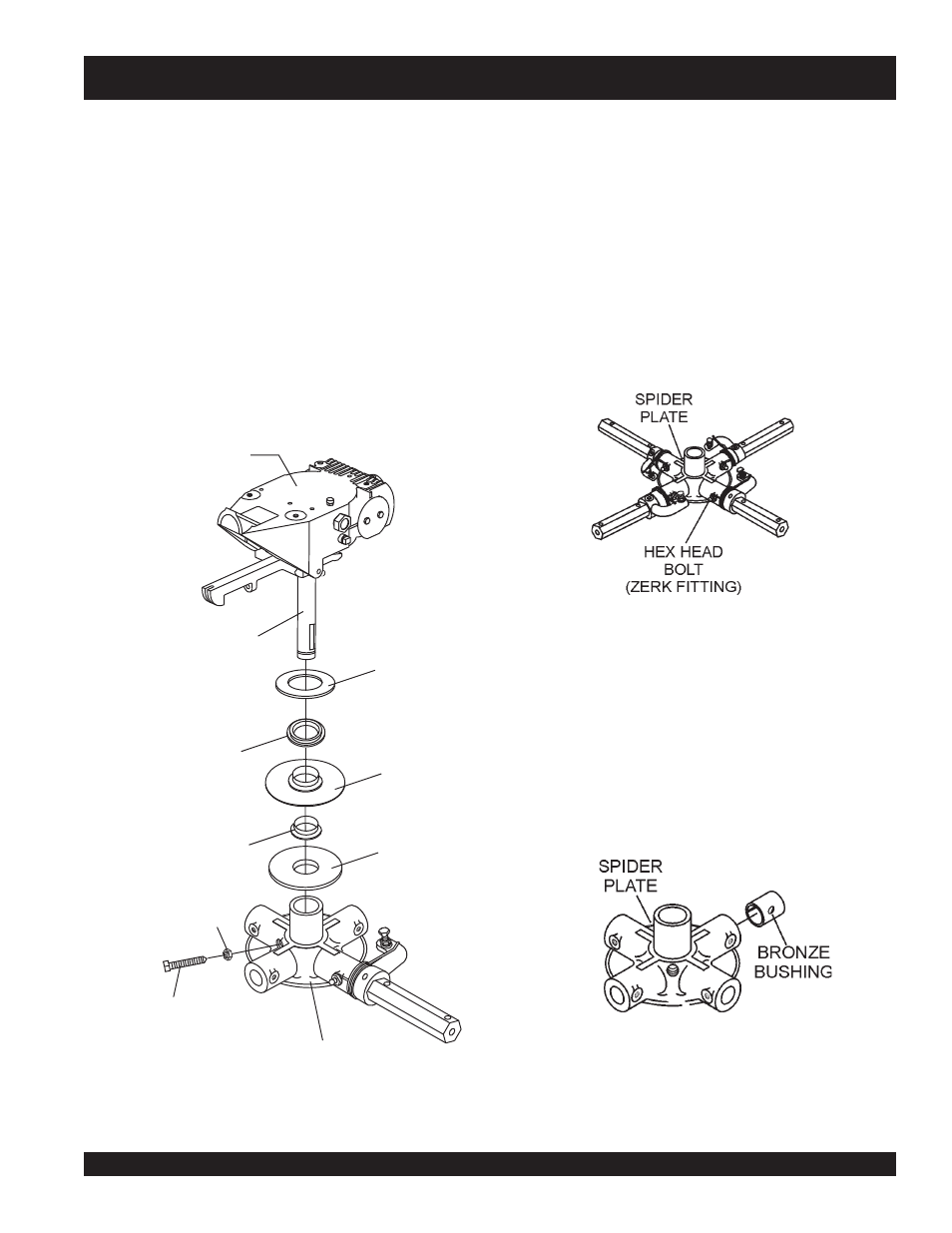

1. Locate the cone point square head set screw (Figure 40) and

attached jam nut found on the side of the spider assembly.

Spider Removal

If an adjustment is required, remove the spider assembly from

the gearbox shaft as follows:

Figure 40. Spider/Gearbox Removal

2. Loosen the jam nut and cone point square head set screw,

and carefully lift the

upper trowel assembly

off of the spider

assembly. A slight tap with a rubber mallet may be necessary

to dislodge the spider from the main shaft of the gearbox.

Trowel Arm Removal

1. Each trowel arm is held in place at the spider plate by a hex

head bolt (zerk grease fitting). Remove the hex head bolt

(Figure 41) from the spider plate.

2. Remove the trowel arm from the spider plate.

Figure 41. Removing Roll Pin

and Zerk Grease Fitting

SPIDER

PLATE

CONE POINT

SQUARE HEAD

SET SCREW

JAM

NUT

GEARBOX

UPPER

WEAR PLATE

THRUST

COLLAR

BEARING

THRUST

COLLAR

BUSHING

LOWER

WEAR PLATE

THRUST

COLLAR

GEARBOX

SHAFT

3. If the trowel arm inserts (bronze bushing ) come out with the

trowel arm, remove the bushing from the trowel arm and set

aside in a safe place. If the bushing remains inside the spider

plate, carefully remove the bushing.

4. Examine the bronze trowel arm bushing insert (Figure 42),

and clean if necessary. Replace the bushing if it is out of round

or worn.

Figure 42. Bronze Bushings