Maintenance – Multiquip MRH800DS2 User Manual

Page 30

PAGE 30 — MRH800DS2 VIBRATORY ROLLER • OPERATION AND PARTS MANUAL — REV. #1 (04/12/11)

MACHINE MAINTENANCE

1. At the end of each day’s operation, wash down dust

and dirt off the machine. Clean area around drums ad

scrapers making sure all mud is removed.

2. Drain water tank completely.

3. Cover the machine to prevent dust and store in dry

place away from sun exposure.

LONG TERM STORAGE

1. Conduct thorough lubrication and oil change.

2. Disconnect battery terminals and dismount battery

from machine. Store battery.

3. If there a possibility that ambient temperature will drop

below freezing point, add antifreeze agent to coolant.

4. Cover the inlet and outlet of air cleaner and muffl er

securely.

5. Store machine indoors. Do not leave outdoors.

6. Refer to Table 8 for lubrication necessary for the

machine.

BATTERY MAINTENANCE

1. Use a fl ashlight to check battery electrolyte level.

Always check that the engine is stopped.

2. If a battery has not been used for some time, reduce

the charge level initially to protect each plate inside

the battery.

3. Check the battery terminals periodically to ensure that

they are in good condition.

4. Use wire brush or sand paper to clean the battery

terminals.

5. Check battery for cracks or any other damage. If

white pattern appears inside the battery or paste has

accumulated at the bottom, replace the battery.

6. Measure the specifi c gravity of electrolyte:

NOTICE

Read and understand the battery safety information in

the front of this manual before performing maintenance

on the battery.

MAINTENANCE

• completely charged: 1.270 - 1.290

• needs charging: 1.260 or lower.

7. If the machine will not be in operation for a long period

of time, charge the battery suffi ciently, tighten all caps

correctly, store in cool dry place and check the battery

charge level every month to maintain the performance

of the battery.

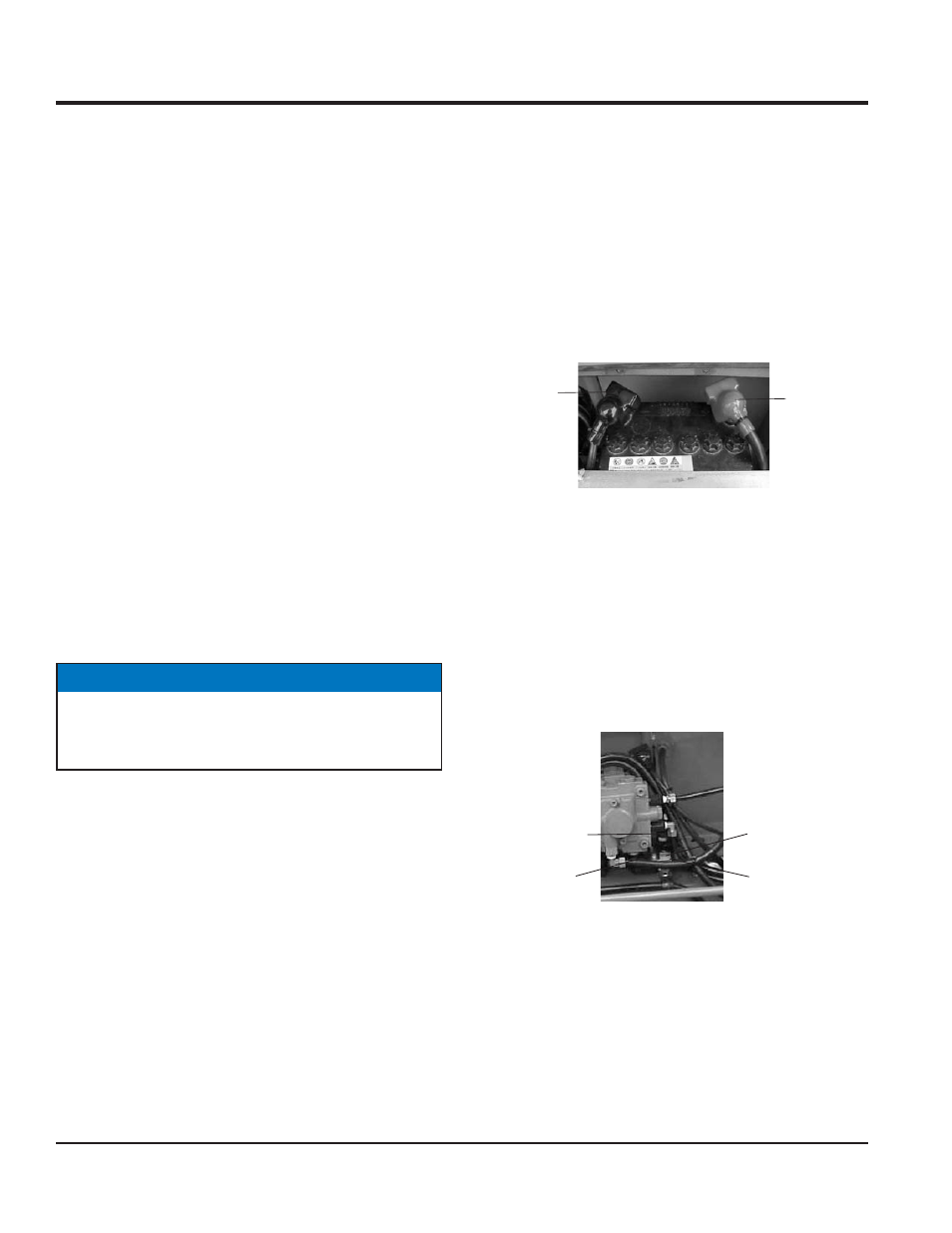

BATTERY CABLE CONNECTION

1. When removing cable, disconnect the ground side

(normally negative) fi rst (Figure 23).

Figure 23. Battery Connection

FORWARD AND REVERSE TRAVEL ADJUSTMENT

2. If neutral position for forward and reverse travel has

been displaced, conduct the neutral adjustment.

3. If roller travels forward with the ball of ball plunger

remaining in V slot of the guide, loosen M8 bolt and

slide the slide plate slightly toward the engine. If the

roller travels backward, slide the plate towards side

plate (Figure 24).

Figure 24. Adjustment of Neutral Position

4. When installing cable, connect the ground side

(normally negative) last.

5. With M8 bolt tightened, start engine and check the

neutral for forward and reverse. If still displaced, repeat

the procedure.

6. If neutral position of forward/reverse lever has been

displaced, use the turn buckle located on the oil pump

side of forward/reverse cable.

NEGATIVE

TERMINAL

POSITIVE

TERMINAL

PLUNGER

GUIDE

SIDE PLATE

M8 BOLT