MTS Series 252 Servovalves User Manual

Page 26

Series 252 Servovalve Product Information

26

252 Servovalve Installation

Installation

Servovalve Locating Pin

Note

For mounting the Model 252.2x and 252.4x servovalves use four 5/16-18

x 1-1/2 in. ASTM A574 socket head cap screws and the Model 252.3x

servovalve uses four 3/8-16 x 1-3/4 in. ASTM A574 socket head cap

screws. As the screws are successively tightened, those previously

tightened will lose clamping force. Continue tightening until all screws

are at the specified torque.

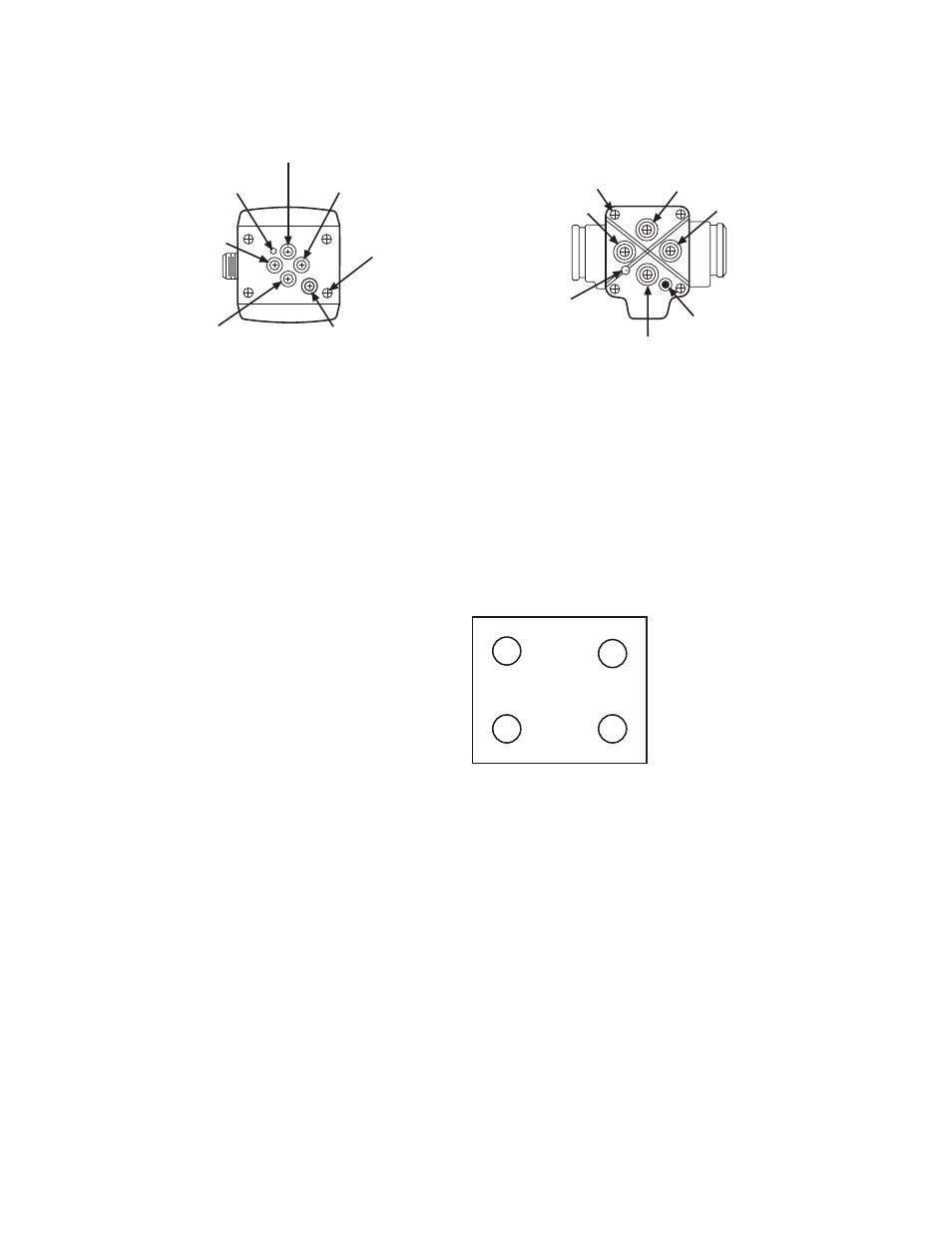

5. After lubricating the mounting screws with a light film of oil, tighten each

one until it is firmly seated. Using the sequence shown, tighten the socket

head screws to 5 lbf·ft.

•

Continue using the pattern and tighten the socket head screws to a final

torque of 13-19 lbf·ft for 252.2x and 252.4x servovalves.

•

Continue using the pattern and tighten the socket head screws to a final

torque of 23-34 lbf·ft torque for 252.3X servovalves.

Note

For manifolds machined with metric threads, the requirements are as

follows:

252.2X and 252.4X Servovalves: M8 x 1.25 mm x 40 mm long socket

head cap screws (DIN 912 Class 12.9). Final torque 19-28 N·m.

252.3X Servovalves: M10 x 1.5 mm x 45 mm long (DIN Class 12.9. Final

torque 36-53 N·m.

6. Connect the four-pin electrical cable from the controller to the servovalve.

7. Turn on electrical and hydraulic system power.

Locating Pin

Pressure

Port

Control Port No. 2

Mounting Holes

(4 Places)

Return Port

Control Port

No. 1

Pilot Pressure Port

(optional)

Control Port

No. 2

Auxiliary Pilot

Pressure Port

Locating Pin

Control Port No. 1

Mounting Holes

(4 places)

Return Port

Pressure Port

1

2

3

4