Moving the spool, Stopping the spool – MTS Series 252 Servovalves User Manual

Page 15

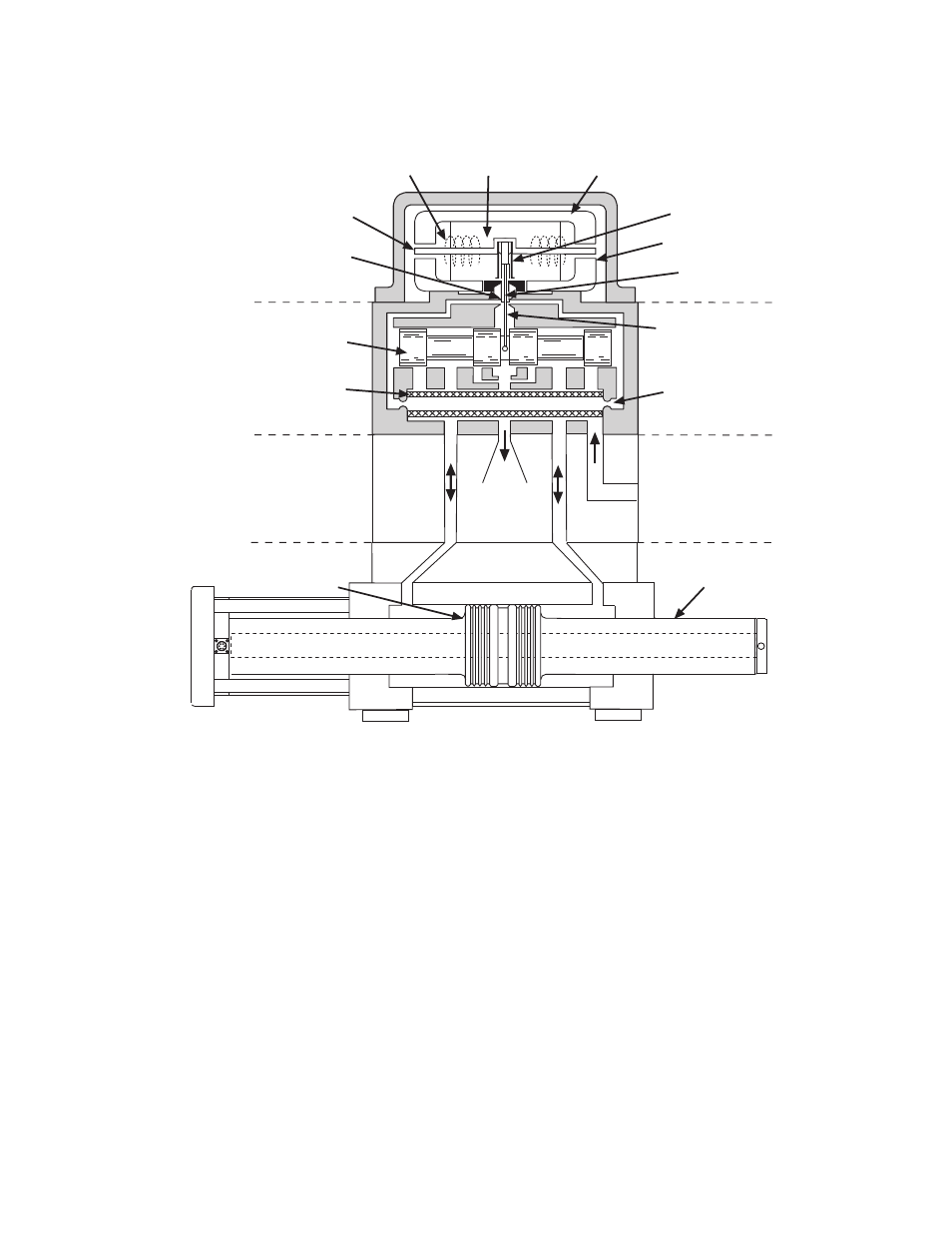

Servovalve Function

Series 252 Servovalve Product Information

Introduction

15

Functional Diagram

Moving the spool

A command from the controller causes the armature to rotate clockwise or

counterclockwise (depending on the polarity of the command). The command

causes the flapper to block one of the nozzles, which diverts hydraulic flow to

that end of the spool. The spool moves and opens hydraulic pressure to one

control port and the return line to the other control port. The control ports are

connected to each end of the actuator.

Stopping the spool

The feedback wire works like a spring. The spool moves until the feedback wire

torque equals the torque from the magnetic forces. This causes the flapper to

move back toward the centered position. The spool stops at a position where the

feedback wire spring torque equals the torque input current of the command. The

spool position is proportional to the input command current.

Although the pressures are equal on both sides of the spool (so the spool is no

longer moving), control flow from the servovalve keeps the actuator moving.

First Stage

Armature

Nozzle

Second Stage

Spool

Filter

Manifold

Actuator

Piston

LVDT (inside rod)

Actuator Rod

Pressure

from Power

Fixed Orifice

Feedback Wire

Flapper

Lower Pole

Flexure Tube

Upper Pole

Magnets

Coil