Manta core drill iii troubleshooting – MK Diamond MK-MANTA III User Manual

Page 17

17

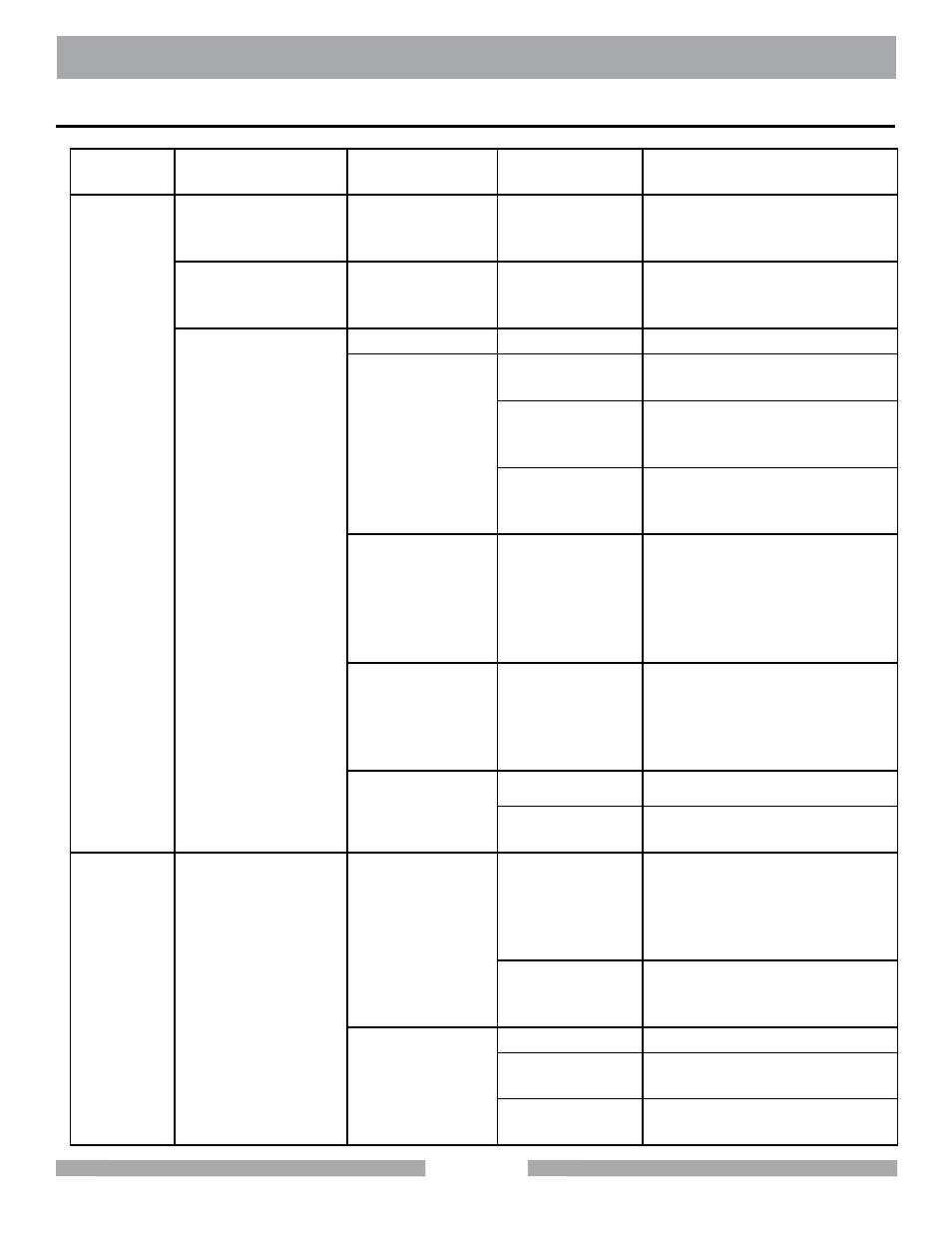

TROUBLESHOOTING

PROBLEM WHAT TO DO?

INDICATION

CAUSE

SOLUTION/

RECOMMENDATIONS

Low Pen-

etration

Rate Under

Prevailing

Drilling Pa-

rameters.

1. Check fluid return. Fluid not muddy.

Evidence of steel

cuttings.

Drilling in steel

reinforcement.

Adjust drilling parameters to

recommendations for reinforce-

ment.

2. Check motor

speed range.

Speed not cor-

rect for the bit

size used.

See recommended speeds.

3. Check wear

picture of bit face.

Bit worn out

Replace with new bit.

Diamond without

exposure. (flush

with bond matrix)

Insufficient bit

load.

Increase bit load.

Rotated with high

RPM on rein-

forcement

Reduce RPM, or resharpen bit.

Loose material at

bottom of hole.

Break core, clean bottom of

hole or reduce RPM and drill

with increased bit load.

Face of bit

plugged with cut-

tings

Not enough fluid

pumped. Cut-

tings burnt to

matrix. Diamonds

prevented from

cutting.

Clean bit face by sharpening

methods such as drilling dry at

low RPM in a concrete block

3/8” deep max. Increase water

flow rate.

Face of bit cov-

ered with steel.

Steel cuttings

stick to bit face.

Steel cuttings

stick to bit face.

Diamonds pre-

vented from

cutting.

Clean bit face by drilling in

abrasive concrete block. Re-

duce RPM.

Wear picture of

polished dia-

monds.

Bit load too low.

Increase bit load.

Bit speed too

high

Use lower speed; increase bit

load.

Heavy

Wear at

Steel Tube

Deep grooves.

Worn or open

guide ways on

cradle. Borehole

is getting undu-

lated.

Adjust guidance on carriage.

Protruding steel.

Spindle is offset.

Bit out of true.

Adjust guidance on carriage.

Nicks or dirt on mounting faces.

Heavy Wear.

Bit is deformed.

Replace bit.

Poor cleaning of

abrasive cuttings.

Improve flushing.

Crown clearance

worn out.

Replace bit.

MANTA CORE DRILL III

TROUBLESHOOTING