MK Diamond MK-212 User Manual

Page 32

32

MK-212 SAW

MAINTENANCE

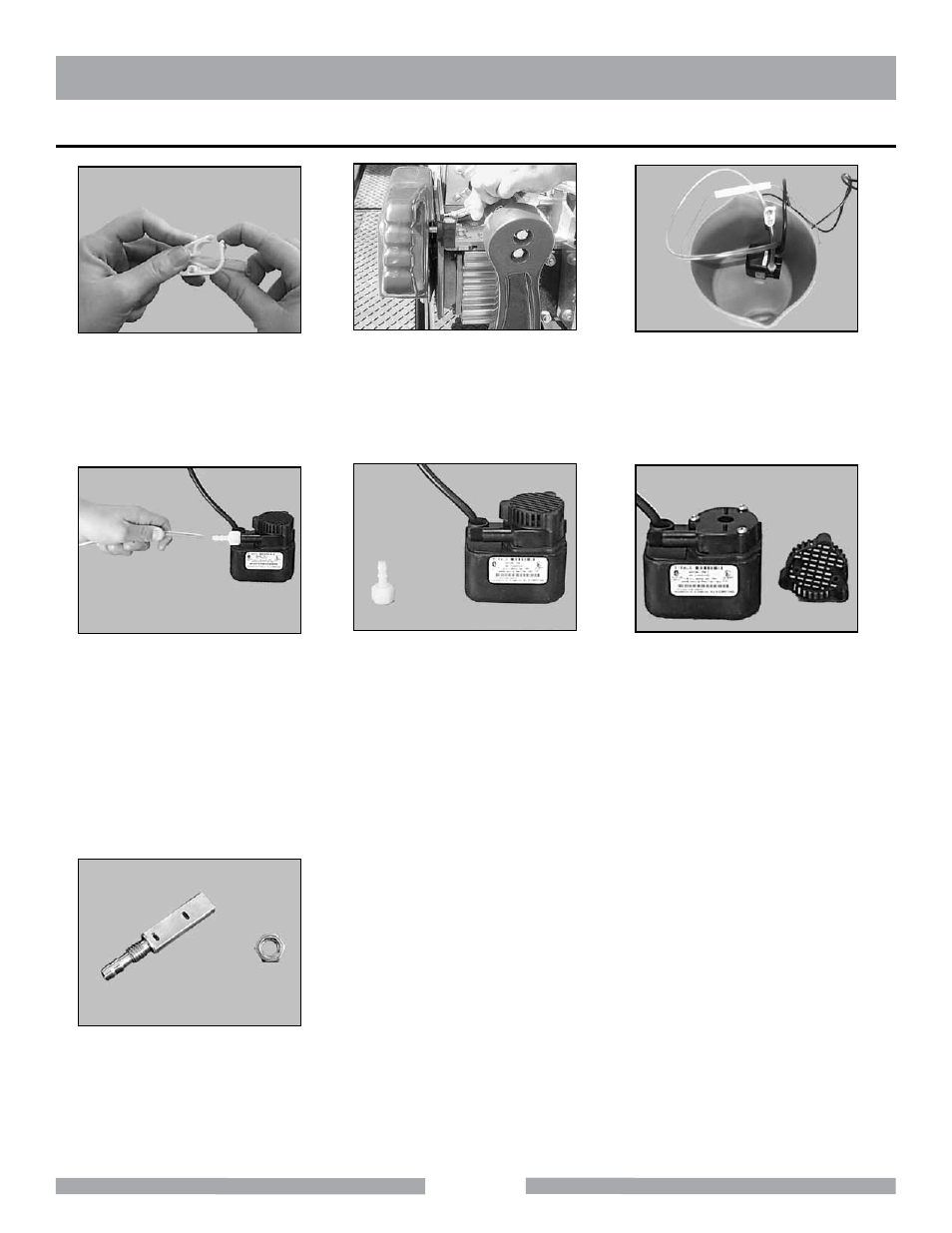

COOLING FLOW

(B)

Remove the Cooling Transfer

Tube from the Blade Guard inlet.

(A)

Verify the cooling flow Adjusting

Clamp is open.

(C)

Place Pump into a bucket of water

and check flow.

(E)

Remove the Pump Discharge

Fitting and check for flow.

(D)

Remove the Cooling Transfer

Tube and check for flow.

(F)

Remove the Pump Intake Screen

and check for debris – clean the

screen if necessary.

NOTE: “Rodding” cooling channels is performed by inserting a small wire rod through the cooling

inlet on top of the Blade Guard and directing the rod out through each of the cooling flow tubes lo-

cated on the underside of the Blade Guard. The cooling channels should be “rodded” until all ports

are free of foreign debris.

(G)

Rod (clean out) the Cooling

Manifold and then recheck flow.

- MK-770 (41 pages)

- MK-770 EXP (46 pages)

- MK-660 (44 pages)

- MK-470 (12 pages)

- MK-377 (36 pages)

- MK-370 (36 pages)

- MK-370 EXP (52 pages)

- MK-170 (36 pages)

- MK-145 (32 pages)

- MK-145 220 Volt (32 pages)

- MK-101 (52 pages)

- MK-101 (56 pages)

- MK-101-24 (52 pages)

- MK-101-24 (56 pages)

- MK-101 Pro / Pro24 (56 pages)

- MK-101 Tracker (45 pages)

- MK-101Pro24 JCS (60 pages)

- MK-101 JCS Rental (51 pages)

- MK-101 Lowes (56 pages)

- MK-101 Lowes (52 pages)

- MK-100 (44 pages)

- MK-100 (52 pages)

- MK-100 Tracker (46 pages)

- MK-100 JCS (49 pages)

- TX-3 (52 pages)

- Saw Tent (2 pages)

- MK-112 (28 pages)

- MK-1070 (22 pages)

- MK-1590 (36 pages)

- MKDX Profile Milling Machine (40 pages)

- MK-EZ Profile Milling Machine (36 pages)

- MK-1503SS (24 pages)

- MK-1080 (44 pages)

- MK-1080 (1 page)

- MK-1080 (3 pages)

- MK-1280 Gas Saw (48 pages)

- MK-1280 Electric Saw (40 pages)

- MK-1280 Rolling Cart (4 pages)

- MK-1270 (Shindaiwa) (28 pages)

- MK-2000 Electric Saws (52 pages)

- MK-2000 Gas (60 pages)

- MK-5005S (56 pages)

- MK-5000 Gas Saws (56 pages)

- BX-3 (36 pages)