Mayline Under-Board Rule Attachment User Manual

Mayline Hardware

NOTE: Please count and inspect all pieces before disposing of any carton or packing materials.

When ordering components, specific color and/or size information may be required.

Contact a Mayline Customer Service Representative. 1-800-822-8037

COMPONENTS:

REF. # QTY. DESCRIPTION PART No.

1 1 CABLE COIL ASSEMBLY CALL~~

2 1 UPPER RIGHT PULLEY A1085

3 1 UPPER LEFT PULLEY A1086

4 1 LOWER RIGHT PULLEY A1087

5 1 LOWER LEFT PULLEY A1088

6 2 ATTACHMENT CLAMP KIT A1089

HARDWARE BAG (PART No. A104)

*for individual item, order that part number

REF. # QTY. DESCRIPTION PART No.

E1 4 WASHER W26*

E2 8 #6 x 1/2 SCREW X37*

INSTALLATION INSTRUCTIONS

for UNDER-BOARD RULE ATTACHMENT

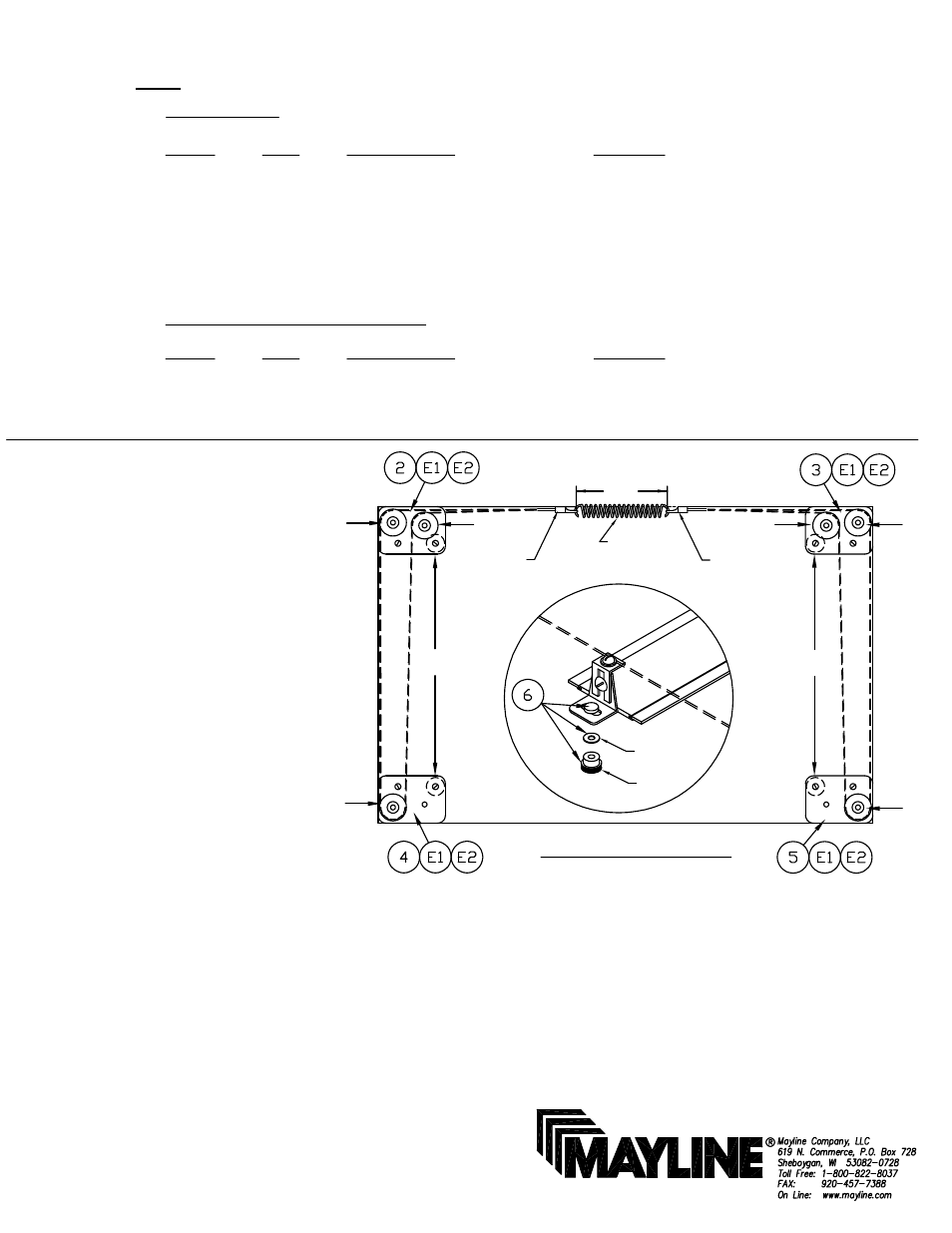

1. Attach the four pulley assembly

plates to the underside of the board.

Place single pulley units to the front

corners and double pulley units to the

rear corners as shown.

NOTE: When attaching to steel tops,

drill 1/8" holes to mount pulley assembly

plates. When this attachment is used

on a Mayline Steel End Cleat board,

place a Washer (E1) as a shim under

the inside corner of each pulley plate as

indicated by arrows "G".

2. Crimp Ring Terminal to one end of

cable. Do not twist or kink cable.

3. Startling from Top Center of board,

thread end of cable around pulley "A" to

front of board around pulley "B", then

back around pulley "C". Now cross the

board and thread around pulley "D",

then to front of board around pulley "E"

and back around pulley "F".

4. Connect Ring Terminal and cable to

spring. Slide 2nd Ring Terminal on

opposite end of cable and attach Ring

Terminal to other end of spring. Hold

Ring Terminal and pull cable until spring

is extended 1/2" to 3/4". Crimp terminal

in this position. Be sure that the cable

runs freely.

5. Place straightedge in position on board and fasten blade

clamps (shown upside down, Fig.1) to ends of straightedge

with knurled nuts. Adjust sliding bar to correct length and

tighten screws.

6. Loosen cable clamp screws on bottom of blade clamps

and place cable between washer and groove in blade

clamps, align straightedge and clamp cable by tightening

cable clamp screws. Straightedge can be removed from

blade and replaced without changing alignment by simply

removing knurled nuts.

UNDERSIDE OF BOARD

Fig. 1

D

F

G

E

G

A

C

B

CATALOG No.

7302A

7302B

7302C

~~Denotes Size

SPRING

SPRING LENGTH

NOT TO EXCEED

3.50

WASHER

KNOB

RING

TERMINAL

RING

TERMINAL