Longevity ARCMATE 205 User Manual

Page 30

160/205 MIG Welder/ARC Welder

Page 29 of 37

www.longevity-inc.com

Operation

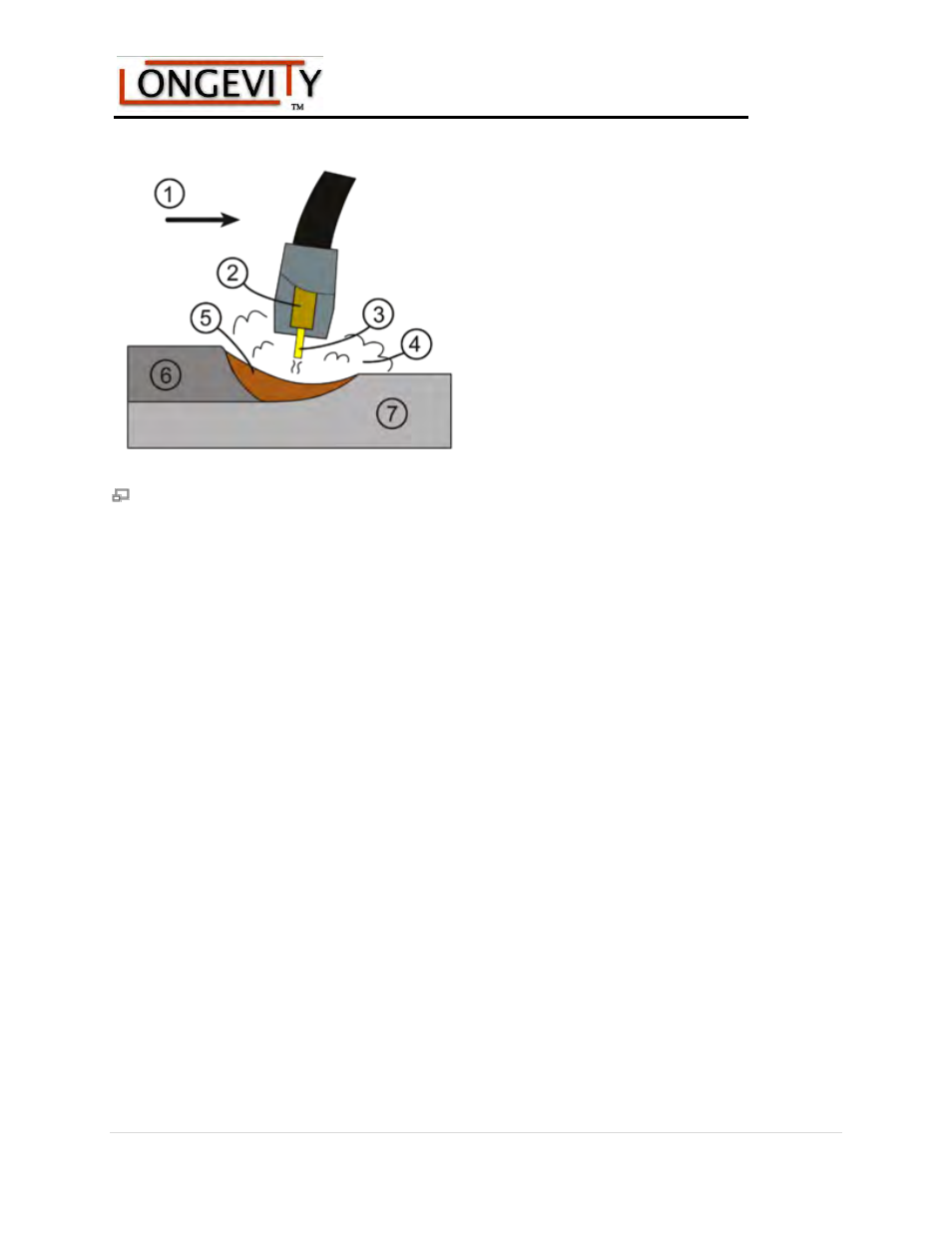

GMAW weld area: (1) Direction of travel (2) Contact tube (3) Electrode (4) Shielding gas (5) Molten

weld metal (6) Solidified weld metal (7) Work piece

For most of its applications gas metal arc welding is a fairly simple welding process to learn

requiring no more than a week or two to master basic welding technique. Even when welding is

performed by well-trained operators weld quality can fluctuate since it depends on a number of

external factors. All GMAW is dangerous, though perhaps less so than some other welding

methods, such as shielded metal arc welding.

Technique

The basic technique for GMAW is quite simple, since the electrode is fed automatically through

the torch. By contrast, in gas tungsten arc welding, the welder must handle a welding torch in

one hand and a separate filler wire in the other, and in shielded metal arc welding, the operator

must frequently chip off slag and change welding electrodes. GMAW requires only that the

operator guide the welding gun with proper position and orientation along the area being welded.

Keeping a consistent contact tip-to-work distance (the stick out distance) is important, because a

long stickout distance can cause the electrode to overheat and will also waste shielding gas.

Stickout distance varies for different GMAW weld processes and applications. For short-circuit

transfer, the stickout is generally 1/4 inch to 1/2 inch, for spray transfer the stickout is generally

1/2 inch. The position of the end of the contact tip to the gas nozzle is related to the stickout

distance and also varies with transfer type and application. The orientation of the gun is also

important—it should be held so as to bisect the angle between the work piece; that is, at 45

degrees for a fillet weld and 90 degrees for welding a flat surface. The travel angle, or lead angle,

is the angle of the torch with respect to the direction of travel, and it should generally remain

approximately vertical. However, the desirable angle changes somewhat depending on the type