Longevity ARCMATE 205 User Manual

Page 26

160/205 MIG Welder/ARC Welder

Page 25 of 37

www.longevity-inc.com

Welding gun and wire feed unit

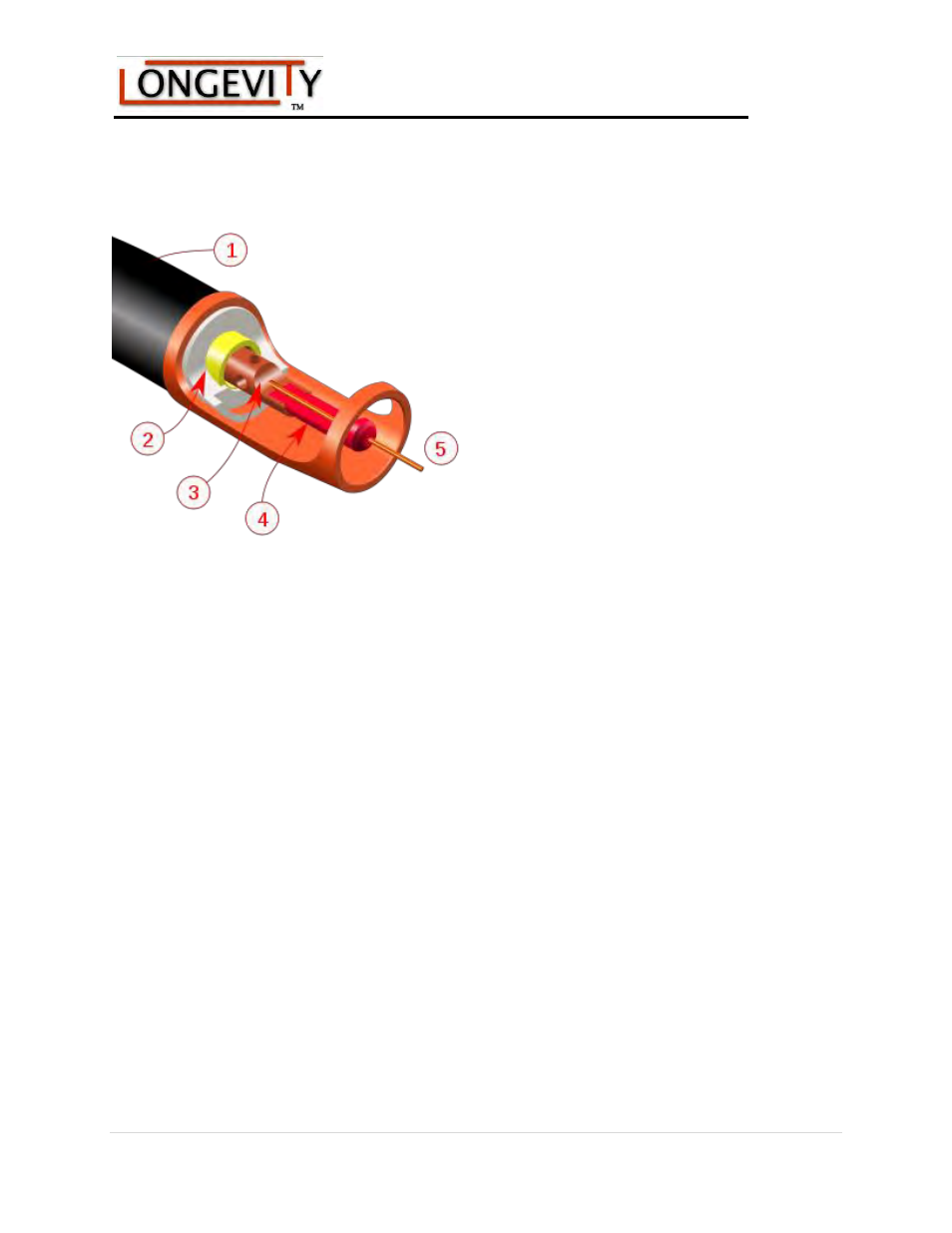

GMAW torch nozzle cutaway image: (1) Torch handle (2) Molded phenolic dielectric (shown in white)

and threaded metal nut insert (yellow) (3) Shielding gas diffuser (4) Contact tip (5) Nozzle output face

A GMAW wire feed unit

The typical GMAW welding gun has a number of key parts—a control switch, a contact tip, a

power cable, a gas nozzle, an electrode conduit and liner, and a gas hose. The control switch, or

trigger, when pressed by the operator, initiates the wire feed, electric power, and the shielding

gas flow, causing an electric arc to be struck. The contact tip, normally made of copper and

sometimes chemically treated to reduce spatter, is connected to the welding power source

through the power cable and transmits the electrical energy to the electrode while directing it to

the weld area. It must be firmly secured and properly sized, since it must allow the passage of the

electrode while maintaining an electrical contact. Before arriving at the contact tip, the wire is

protected and guided by the electrode conduit and liner, which help prevent buckling and

maintain an uninterrupted wire feed. The gas nozzle is used to evenly direct the shielding gas

into the welding zone—if the flow is inconsistent, it may not provide adequate protection of the

weld area. Larger nozzles provide greater shielding gas flow, which is useful for high current

welding operations, in which the size of the molten weld pool is increased. The gas is supplied to

the nozzle through a gas hose, which is connected to the tanks of shielding gas. Sometimes, a

water hose is also built into the welding gun, cooling the gun in high heat operations.