Longevity ARCMATE 205 User Manual

Page 28

160/205 MIG Welder/ARC Welder

Page 27 of 37

www.longevity-inc.com

contain deoxidizing metals such as silicon, manganese, titanium and aluminum in small

percentages to help prevent oxygen porosity. Some contain denitriding metals such as titanium

and zirconium to avoid nitrogen porosity. Depending on the process variation and base material

being welded the diameters of the electrodes used in GMAW typically range from 0.7 to 2.4 mm

(0.028–0.095 in) but can be as large as 4 mm (0.16 in). The smallest electrodes, generally up to

1.14 mm (0.045 in) are associated with the short-circuiting metal transfer process, while the most

common spray-transfer process mode electrodes are usually at least 0.9 mm (0.035 in).

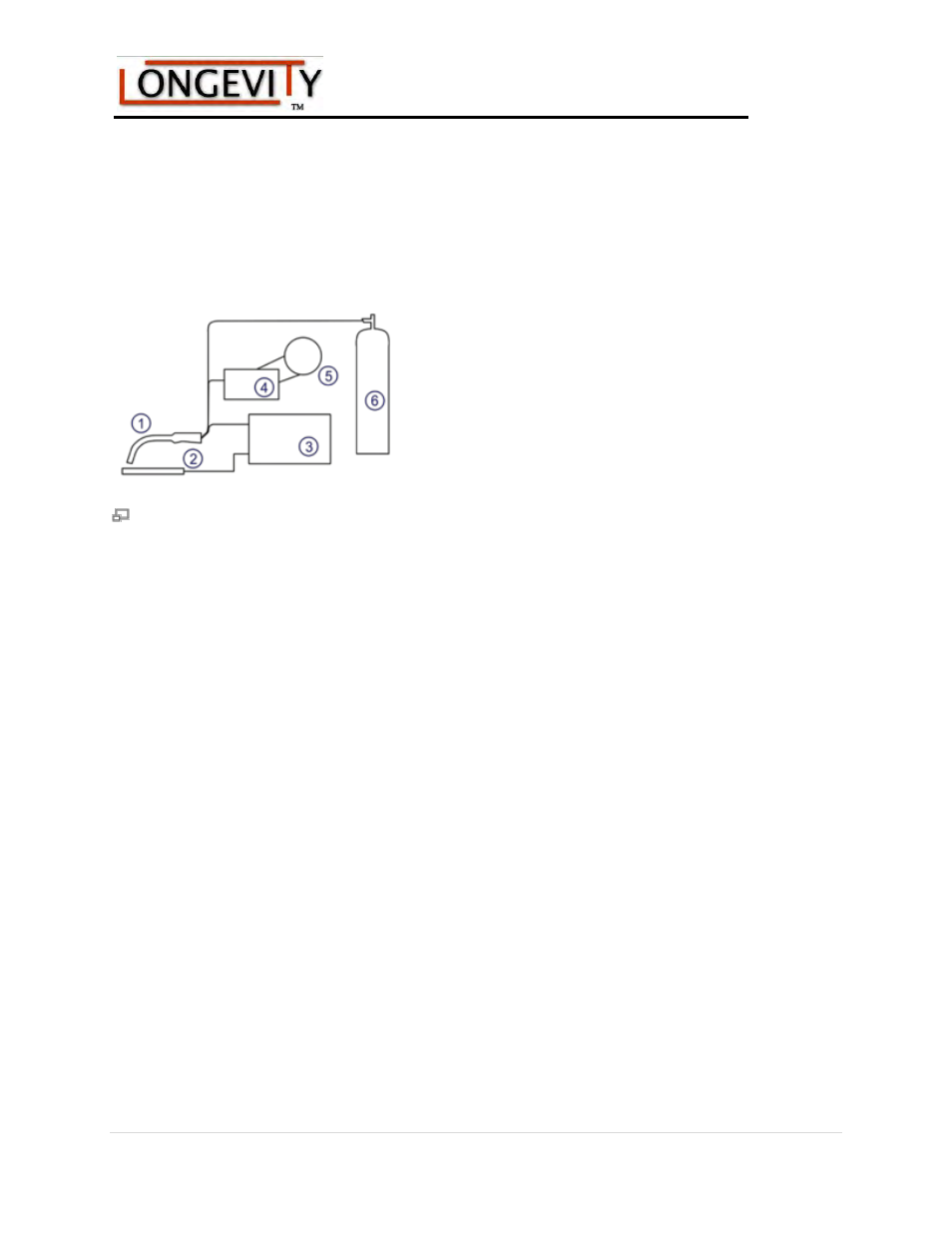

GMAW circuit diagram: (1) Welding torch (2) Work piece (3) Power source (4) Wire feed unit (5)

Electrode source (6) Shielding gas supply

Shielding gas

Main article: Shielding gas

Shielding gases are necessary for gas metal arc welding to protect the welding area from

atmospheric gases such as nitrogen and oxygen, which can cause fusion defects, porosity, and

weld metal embrittlement if they come in contact with the electrode, the arc, or the welding

metal. This problem is common to all arc welding processes; for example, in the older Shielded-

Metal Arc Welding process (SMAW), the electrode is coated with a solid flux which evolves a

protective cloud of carbon dioxide when melted by the arc. In GMAW, however, the electrode

wire does not have a flux coating, and a separate shielding gas is employed to protect the weld.

This eliminates slag, the hard residue from the flux that builds up after welding must be chipped

off to reveal the completed weld.

The choice of a shielding gas depends on several factors, most importantly the type of material

being welded and the process variation being used. Pure inert gases such as argon and helium are

only used for nonferrous welding; with steel they do not provide adequate weld penetration

(argon) or cause an erratic arc and encourage spatter (with helium). Pure carbon dioxide, on the

other hand, allows for deep penetration welds but encourages oxide formation, which adversely

affect the mechanical properties of the weld. Its low cost makes it an attractive choice, but

because of the reactivity of the arc plasma, spatter is unavoidable and welding thin materials is

difficult. As a result, argon and carbon dioxide are frequently mixed in a 75%/25% to 90%/10%

mixture. Generally, in short circuit GMAW, higher carbon dioxide content increases the weld

heat and energy when all other weld parameters (volts, current, electrode type and diameter) are