Troubleshooting – Longevity WeldAll 160PI/200PI/250PI User Manual

Page 47

160/200/250PI AC/DC Series IGBT Machine

www.LWELD.com

Troubleshooting

If your unit is not properly functioning, please call us immediately toll free at 1-877-566-4462 for support. We

have included a small table here to diagnose most common problems.

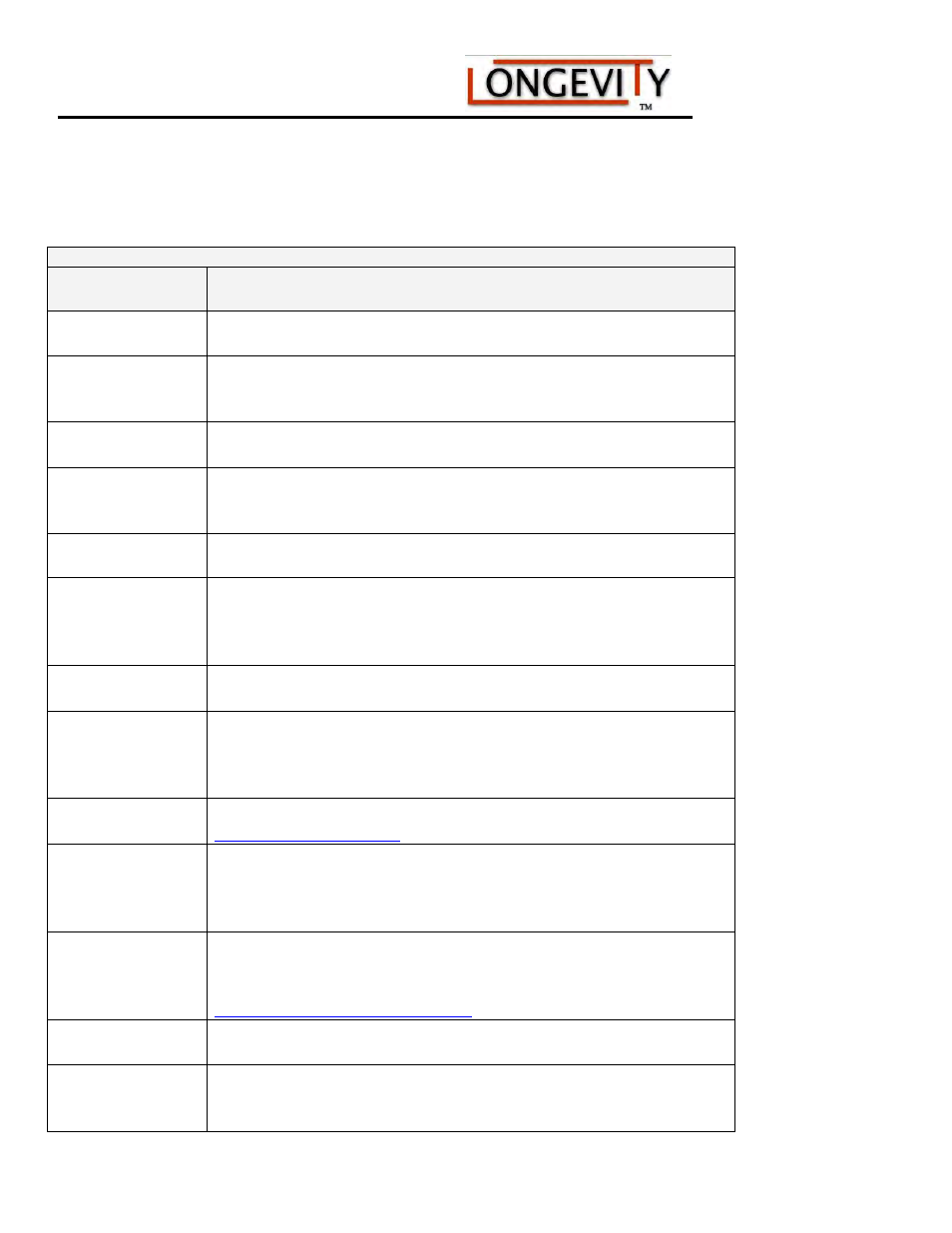

Problems, Causes, and Solutions

Problems

Causes/

Solutions

Machine will not

turn on.

Check cords and breaker. If nothing is found, contact

LONGEVITY

The machine runs,

but nothing is

happening

Check to see if you are in the right mode, plasma cutter, tig,

stick. Check the torches and your ground. Make sure there is argon

or compressed air for plasma and tig.

Pilot Arc will not

start

Check the ground connection. Check the torch for proper

consumables installation. Replace consumables.

Consumables

(tips) are being

consumed

Improper air/gas flow. Increase the PSI on the regulator, check

for leaks in the hose, maintain a distance of 1/8” from the torch tip

or workpiece

Heavy Underside

Slag (Cutting)

Slow travel speed. Increase travel speed or amperage on unit.

Poor Cut Quality

Check Air Pressure. Insure your unit is capable of cutting the

desired thickness of material. Check the consumables to insure they

are producing a stable arc. Replace Consumables and insure you

have the proper PSI at the regulator.

Inconsistent

Arc

Improper grounding or possible lack of air pressure. Check and

replace consumables and adjust the regulator to proper PSI

O.C. Over

Current LED

Lights

The unit has reached its DUTY Cycle. Leave power of the

machine on and allow fans to cool the machine. You can also turn

the machine off to properly cool it. Do not continue to weld until

light is off.

Issue Not Listed

Contact LONGEVITY Toll Free 1-877-566-4462 or via email at

Unit Will Not

Weld

Check ground connection, torch setup, and check if you are in

the proper mode ARC/TIG. If you are TIG Welding check to see if

you have the proper TUNGSTEN and FILLER ROD.

Tungsten is

Melting or Being

Consumed

Quickly

Low Argon Gas flow. Check the Argon Gas flow. Turn up post

flow. Incorrect Tungsten or Incorrect Tungsten Size. Possible

small size shield cup. Read selecting the right tungsten on

www.longevity-inc.com/resources

Contaminated

Tungsten

If the Tungsten is dipping or melting inside the weld. Use

larger tungsten and fewer amps on the unit. Sharpen tungsten.

Poor Weld Quality

Remember to clean welding material prior to welding with

acetone. Practice on the form and technique. Use the right tungsten

and filler rod.