Longevity WeldAll 160PI/200PI/250PI User Manual

Page 43

160/200/250PI AC/DC Series IGBT Machine

www.LWELD.com

weld bead into the sides or “toes” of the weld is important. Keep the welding electrode or the TIG tungsten and

welding arc within the weld joint to prevent overlap. Pausing on the sides of the welds to wait for the sides to fill

reduces the chance of undercutting, even if the current is a little too high. If it is possible, with any practice weld,

cut the joint down the middle, lengthwise, or place the weld in a vice and use a hammer to bend the metal over the

weld area until it is either broken or bent 90 degrees. This destructive testing method will help you improve your

skill by revealing faults and flaws in your welds.

Stick (SMAW)Electrode Welding

Stick, the most basic of welding processes, offers the easiest option for joining steel and other metals. Although

it produces the least pretties or cleanest welds, ARC/STICK welding gets the job done! Stick welding power

sources deliver inexpensive options for welding versatility, portability and reliability. Stick joins metals when

an arc is struck between the electrode and the work piece, creating a weld pool and depositing a consumable

metal electrode into the joint. The electrode's protective coating also acts as a shielding gas, protecting the weld

and ensuring its purity and strength. Best for windy conditions and adverse environments.

If you’re not familiar with Stick (SMAW) welding basics, the following information can make choosing

an electrode easier.

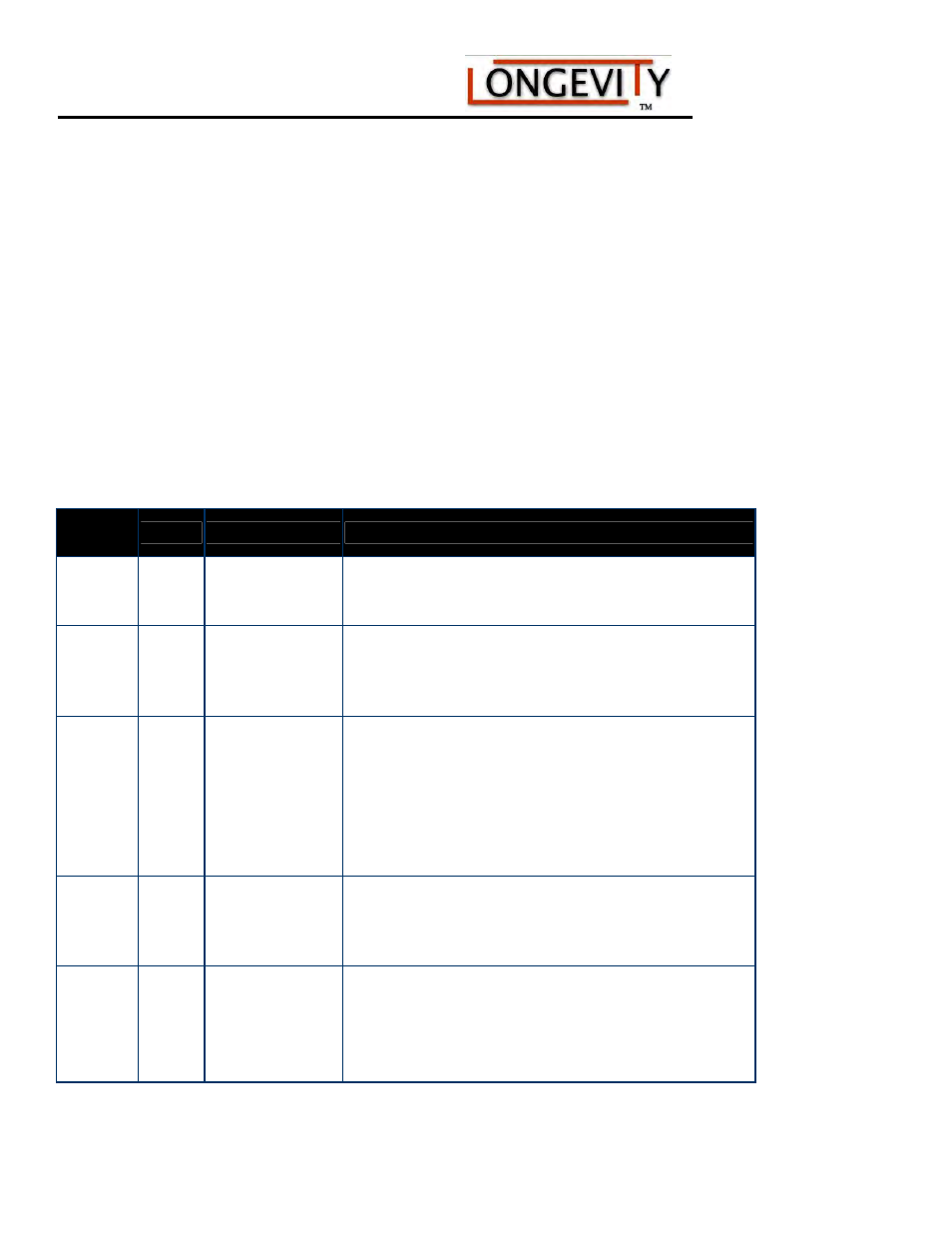

AWS

Class

Position

Polarity

Usage

E6010

All

DCEP

A great choice for welding on dirty, rusty, greasy or

painted steel - especially in vertical or overhead

applications.

E6011

All

AC,DCEP

All-purpose stick electrode; used for carbon and

galvanized steel; 60,000 PSI tensile strength; deep

penetration and ideal for welding light to medium

amounts of dirty, rusty or painted materials.

E6013

All

AC,DCEN,DCEP

Light to medium penetrating all-purpose stick

electrode; for use on carbon steel; 60,000 PSI tensile

strength; good for general all-purpose applications

and joints with poor fit-up.

E7014

All

AC,DCEN,DCEP

For higher-deposition requirements; 70,000 PSI

tensile strength; ideal for applications requiring light

penetration and faster travel speeds.

E7018

All

DCEP

Low-hydrogen electrode; for low, medium and high-

carbon steels; 70,000 PSI tensile strength; ideal for

out-of-position welding and tacking; not

recommended for low-voltage AC Welders.

E7018AC

All

AC,DCEP

Low-hydrogen electrode; for low, medium and high-

carbon steels; 70,000 PSI tensile strength; ideal for

out-of-position welding and tacking; specially

formulated to operate with small 208/230 volt AC

welders.