Longevity WeldAll 160PI/200PI/250PI User Manual

Page 39

160/200/250PI AC/DC Series IGBT Machine

www.LWELD.com

7. When finished welding always let the welder's fan run for a minute or two to cool the machine before turning

the power switch off.

Fig.1

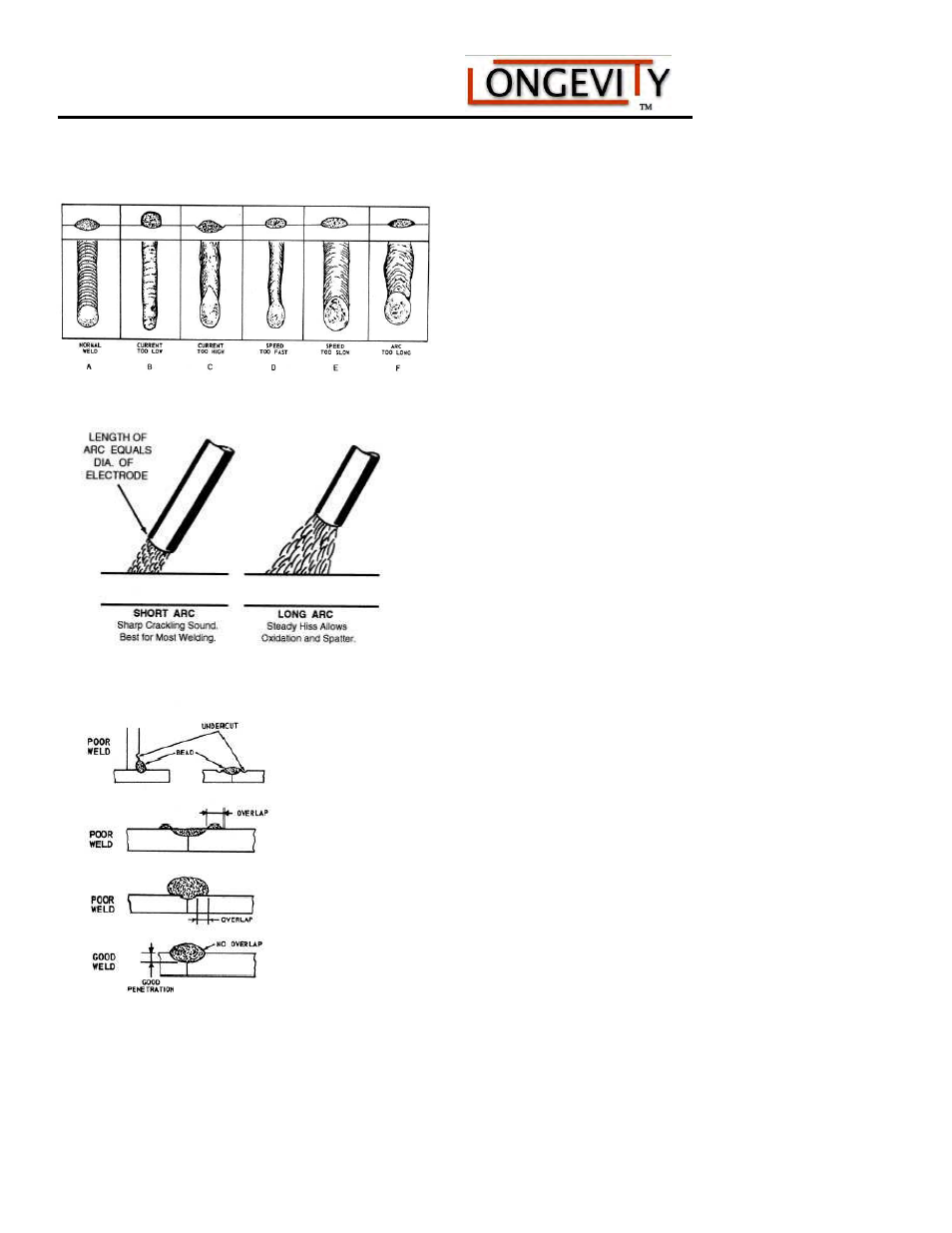

Figure 1: Comparison chart of welds

Fig. 2

Length of Arc When an arc is too long, the metal melts off the electrode in large globules and the arc may

break frequently. This produces a wide, spattered, and irregular deposit with insufficient fusion between the

base metal and the weld. When an arc is too short, it fails to generate enough heat to melt the base metal

properly, causes the electrode Setting the length of an arc to stick frequently to the base metal, and produces

uneven deposits with irregular ripples. The recommended length of the arc is equal to the diameter of the bare

end of the electrode, as shown in figure 3.