8 troubleshooting and fault elimination, Troubleshooting and fault elimination, Troubleshooting and fault elimination 8 – Lenze 13.7xx Motors-Geared motors User Manual

Page 54: 8troubleshooting and fault elimination

Troubleshooting and fault elimination

8

l

54

BA 13.0009 − EN 2.1

8

Troubleshooting and fault elimination

ƒ

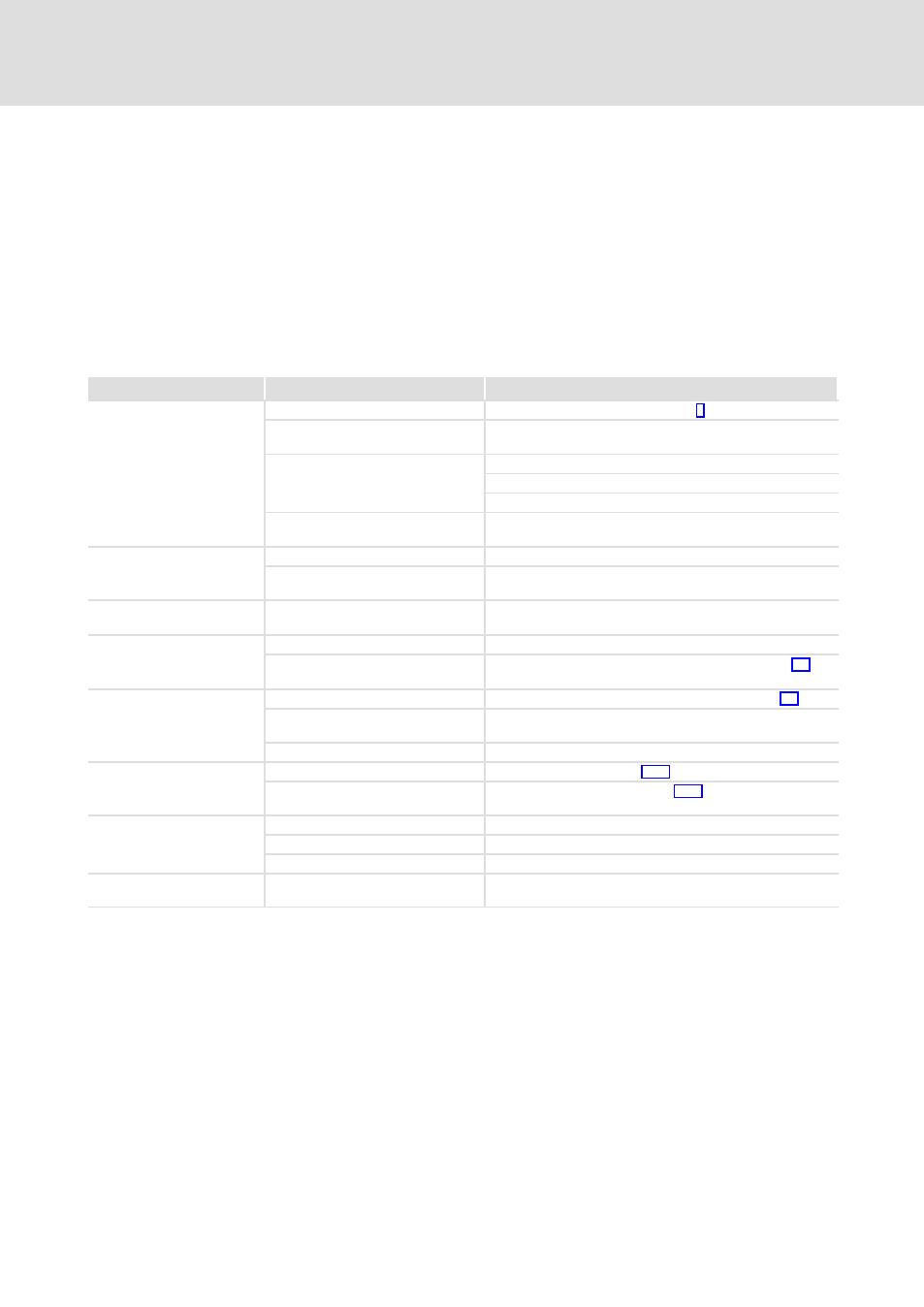

If faults during operation of the drive system occur:

– First check possible error causes by means of the following table.

– Also observe the corresponding chapters in the Operating Instructions of the other

drive system components.

ƒ

If the fault cannot be eliminated by one of the measures itemised, please notify the

Lenze service.

Fault

Possible cause

Remedy

Motor does not start

Voltage supply interrupted

Check electrical connection (chapter 5)

Resisting moment of the load too

great

Check load and, if required, reduce it (check application)

Brake does not release

Check electrical connection

Check air gap "s

Lü

" (see Operating Instructions of brake)

Check duct of the solenoid coil

Drive blocks

Check components with regard to free movement, possibly

remove contaminants from the motor or gearbox

Surface temperature

u95°C Overload of the drive

Check load and, if required, reduce it

Heat dissipation impeded by

deposits

Clean surface of the drives

Motor suddenly stops and

does not start again

Overtemperature protector switch

interrupts voltage supply

Reduce load, let motor cool down (clean, see above)

Running noises

Contaminants inside the motor

Cleaning of the interior, possibly repair by manufacturer

Bearing failures

Mounting of new deep−groove ball bearings (chapter 7.1),

possibly repair by manufacturer

Motor does not rotate,

gearbox output is not

running

Input pinion or worm gear is missing Subsequently mount pinion or worm gear (chapter 5.5)

Wheel−hub connection defective

(overload)

Check connection and, if required, redowel; if required,

reduce load

Toothing worn out

Repair by manufacturer or supplier

Irregular running, motor

stops

Carbon brushes worn out

Replace brush set (chapter 7.1.2)

Carbon brushes are stuck, wear

debris in the guides

Cleaning of the interior (chapter 7.1.2 et seqq.)

Running noises

Carbon brushes are not run in

Support the running−in by means of sanding chalk

Contaminants inside the motor

Cleaning of the interior, possibly repair by manufacturer

Bearing failures

Repair by manufacturer

Speed increase

(Partial) demagnetisation of the

magnet segments

Repair by manufacturer