3 inspection intervals of the pm motors, Inspection intervals of the pm motors, Maintenance/repair – Lenze 13.7xx Motors-Geared motors User Manual

Page 42

Maintenance/repair

Inspection intervals

Inspection intervals of the PM motors

l

42

BA 13.0009 − EN 2.1

7.1.3

Inspection intervals of the PM motors

(

Stop!

Permanent magnetic field!

During mounting and repair, ensure that no contaminants enter the interior of

the motor!

Carbon brushes and, to a limited extent also the collectors, are wearing parts in the case

of commutator machines.

As the wear of the carbon brushes to a great extent depends on the respective operating

conditions, we recommend the following inspection intervals:

– First inspection after approx. 100 operating hours

– Second inspection after 300 further operating hours

Subject the carbon brushes to the following wear control:

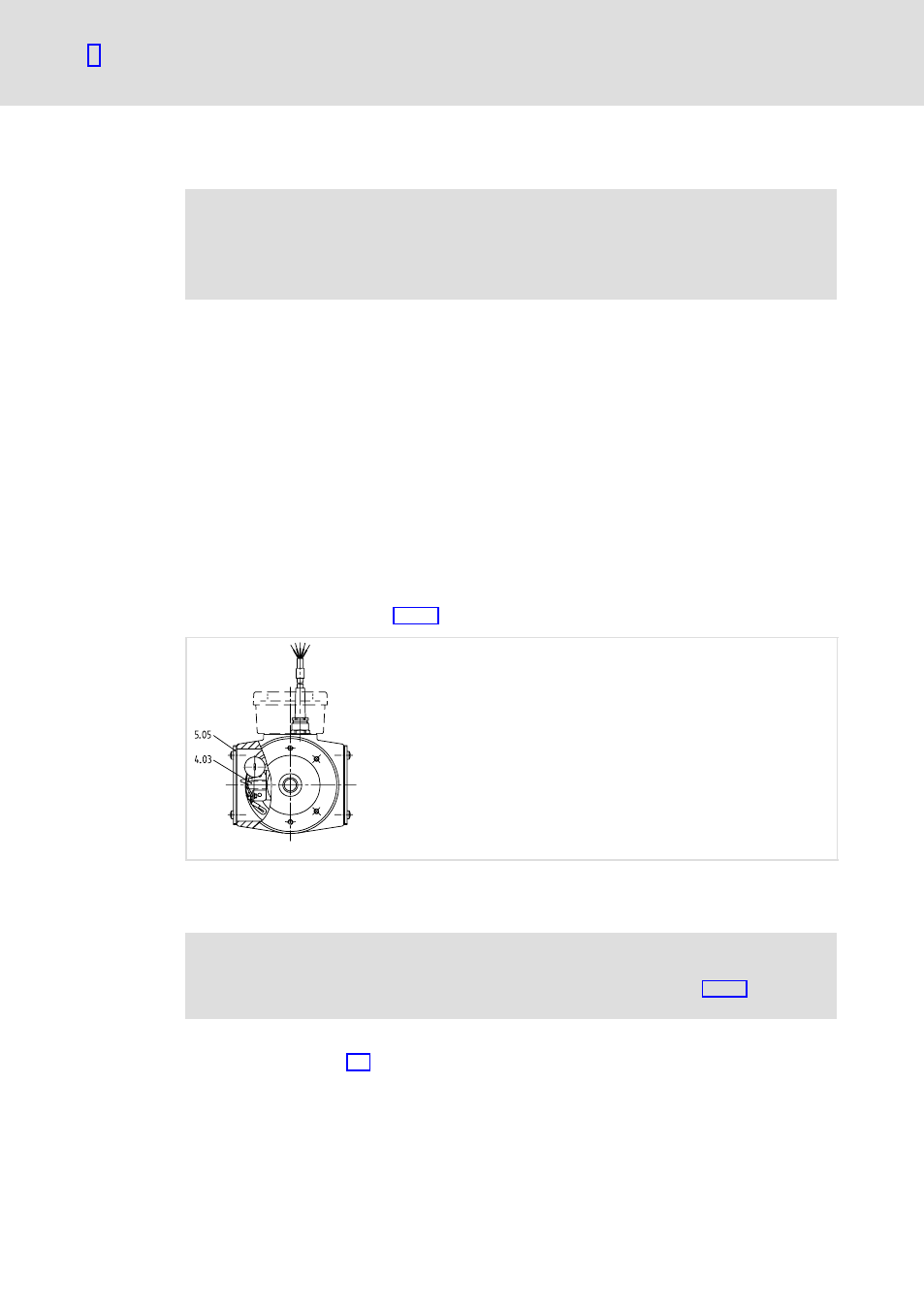

1. Remove the carbon holder covers on the B−bearing shield (pos. 5.05 Fig. 14).

2. Remove, exhaust and vacuum the carbon debris in the interior of the motor using a

brush or similar,

3. Remove the carbon brushes (see Fig. 14) from the guide sleeves,

4. Measure the length (see Tab. 7) with a caliper gauge.

K13.120−23

Fig. 14

Carbon covers

4.03

Carbon brushes

5.05

Cover for carbon brush holders

)

Note!

If the minimum length for the carbon brushes is reached (see Tab. 7), they

basically have to be replaced in sets!

ƒ

Only use original replacement carbons or types approved by the manufacturer, (for

order, see chapter 7.3)!

ƒ

Use carbon brushes so that they smoothly slide in the brush holders.

ƒ

Install pigtails so that the carbons can unimpededly follow through if they are

shortened due to wear.

ƒ

Support the running−in of the carbon brushes, if required by using sanding chalk.