Troubleshooting and fault elimination 9 – Lenze SDSGS User Manual

Page 39

Troubleshooting and fault elimination

l

39

BA 13.0011−EN 1.0

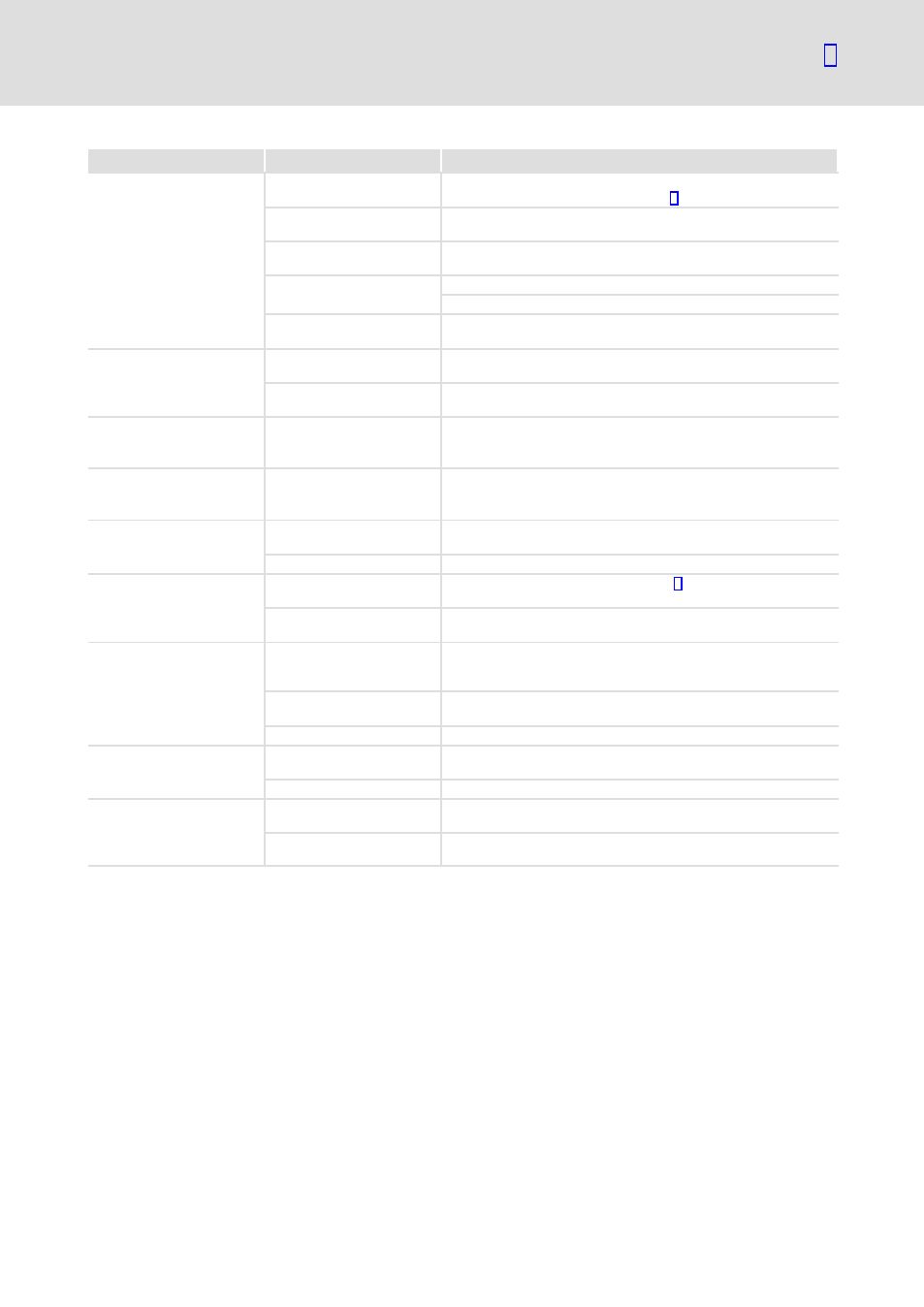

Fault

Cause

Remedy

Motor does not start

Voltage supply interrupted

l

Check error message at the controller

l

Check electrical connection (chapter 6)

Controller inhibited

l

Check display at drive controller

l

Check controller enable

Resolver cable is interrupted

l

Check error message at the controller

l

Check resolver cable

Brake does not release

Check electrical connection

Check continuity of magnetic coil

Drive blocks

Check components for easy movement, remove foreign particles if

necessary

Motor suddenly stops and

does not restart

Overtemperature protector

switch is activated

l

Let motor cool down

– Reduce the load by prolonging the acceleration times

Overload monitoring of the

inverter is activated

l

Check controller settings

l

Reduce the load by prolonging the acceleration times

Incorrect direction of

rotation of the motor, correct

display on the controller

Reversed motor cable and

resolver cable

Exchange 2 phases of the motor cable

and

the +COS/−COS connections of the resolver

Motor rotates slowly in one

direction and cannot be

influenced by the controller

Polarity reversal of motor or

resolver cable

Exchange 2 phases of the motor cable

or

the +COS/−COS connections of the resolver

Motor does not rotate,

gearbox output is not

running

Defective wheel−hub

connection

Check the connection, replace the keyway, if necessary, repair by

the manufacturer

Toothing worn out

Repair by manufacturer

Irregular running

Insufficient shielding of

motor or resolver cable

Check shielding and grounding (chapter 6)

Drive controller gain too

large

Adjust the gains of the controllers (see Drive controller operating

instructions)

Vibrations

Insufficiently balanced

coupling elements or

machine

Rebalance

Poor alignment of the drive

train

Realign machine unit, check foundation if necessary

Loose fixing screws

Check and tighten screw connections

Running noises

Foreign particles inside the

motor

Repair by manufacturer, if necessary

Bearing damage

Repair by manufacturer, if necessary

Surface

temperature > 150 °C

Overload of the drive

Check load and, if necessary, reduce load by prolonging the

acceleration times

Heat dissipation impeded by

deposits

Clean surface and cooling fins of the drives