Page 09 – Kifco T45x1320 400,000 - Present Operator Manual User Manual

Page 13

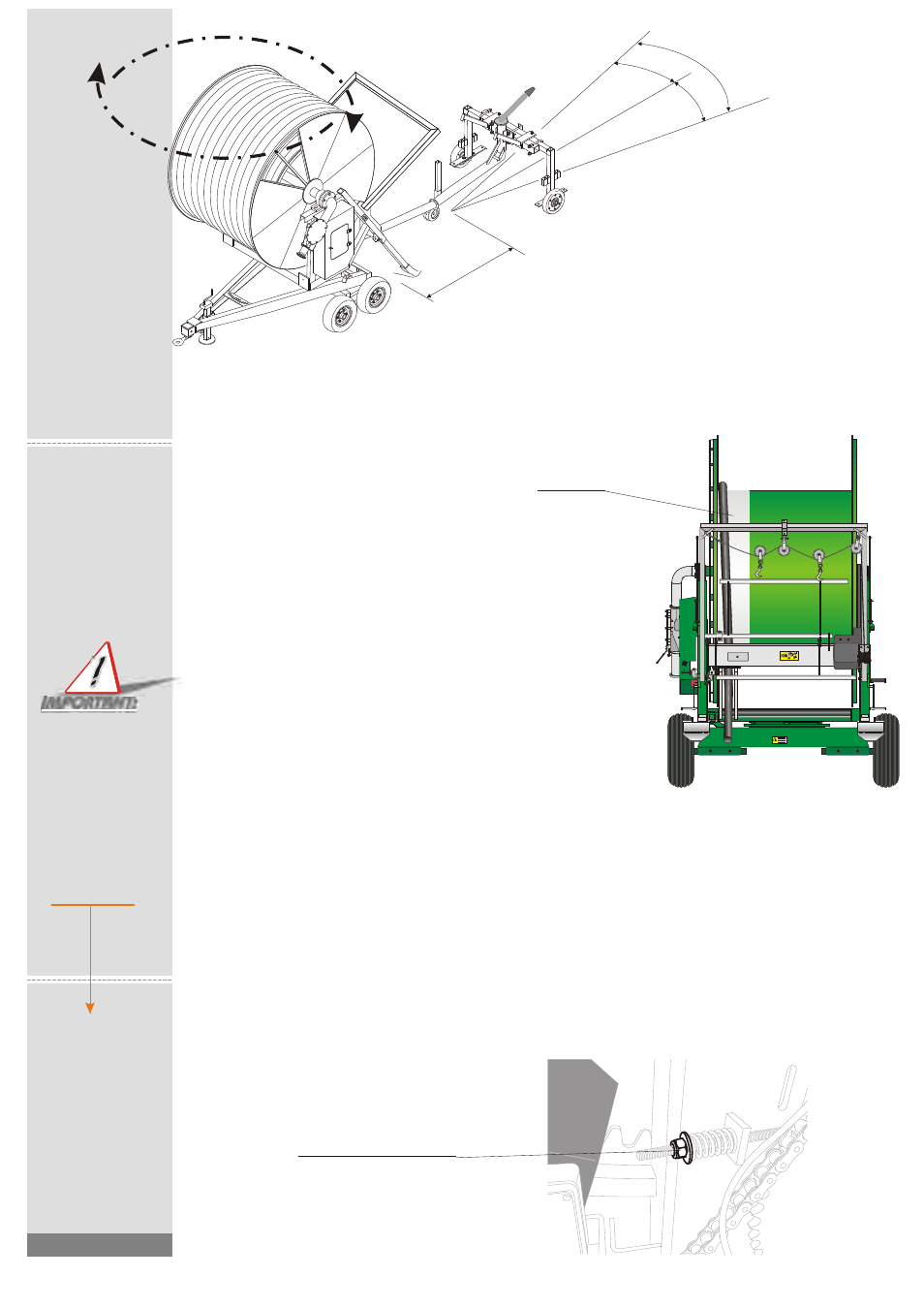

30°

30°

60°

Fig. 15

Fig. 15

Fig. 16

Fig. 16

e)

IMPORTANT:

IMPORTANT:

- Align

To the white part

- Attention

- The first 60

meters

- The variation

of trajectory

- Brake

- During the

unwinding

to verify the brake.

the drum with the furrow.

The variation of trajectory must be always progressive.

When the tube is unwound to follow

the contour of an obstacle (electric post,

dwelling, various buildings, etc..) The variation of

trajectory must be always progressive. Never

make an angle greater than to 90° on the entire length

of the tube. Following its track, the tube will roll up

avoiding the obstacles.

The first 60 meters must be aligned

- it is very likely that the tube is not always aligned with the

machine; the requirements of the land sometimes oblige some

curves. It is important that the first 60 mt. of unwound tube

are aligned. The disregard of this limitation may break the

fork or levelwind and may damage the tube.

- Harness the tractor to the trolley, and unwind

the PE hose slowly and regularly (pic.14) until

the white part painted on the drum appears (pic.16)

t

First 60

me

ers

White part

Nut (M10) for regulation

- Harness the tractor to the trolley, and unwind

the PE hose slowly and regularly (pic.14) until

the white part painted on the drum appears (pic.16)

It is imperative to leave at least one wrap of hose

on the drum to avoid the distortion of the hose at its connection.

When starting a new hosereel for the first time. It is important

that the tube be pulled nearly all the way out in order to tighten

the new tube on the drum.

Never transport the hoseReel with the anti-return pawl disengaged! The

tubing will become loose and tangled. Do not attempt to operate if there

are any coils of tube that are loose or misplaced. If loose coils of tube are noticed after pulling the tube out,

they must be tightened up by rotating the spool with the hand crank. If this is not possible, pull all of

the tube out before attempting to rewind the tube. Never try to move or relocate the machine if the tube is

not fully rewound onto the machine. Never run over the tube with any kind of vehicle and avoid pinching or

pulling the tube around objects. Make it a point to never bend the tube sharper than 15 times the diameter

of the tube. Avoid using the PTO or engine drive to rewind the tube when it is un-pressurized. When the tube

is not pressurized the tube flattens and the rewind mechanism can not function properly. Keep the tube

pressurized when rewinding!

- use of the brake: At the time of unwinding you must adjust the brake. The brake must be tightened

sufficiently to avoid the PE tube relaxing on the drum.

- During unwinding, the spool must stopped turning at the same moment that the tractor stops pulling.

Page 09