Maintenance & adjustments – Kifco E23 360,000 - Present: Operator Manual User Manual

Page 31

T23_AA_Operator Manual_2014

Revised 08/2014

Maintenance & Adjustments

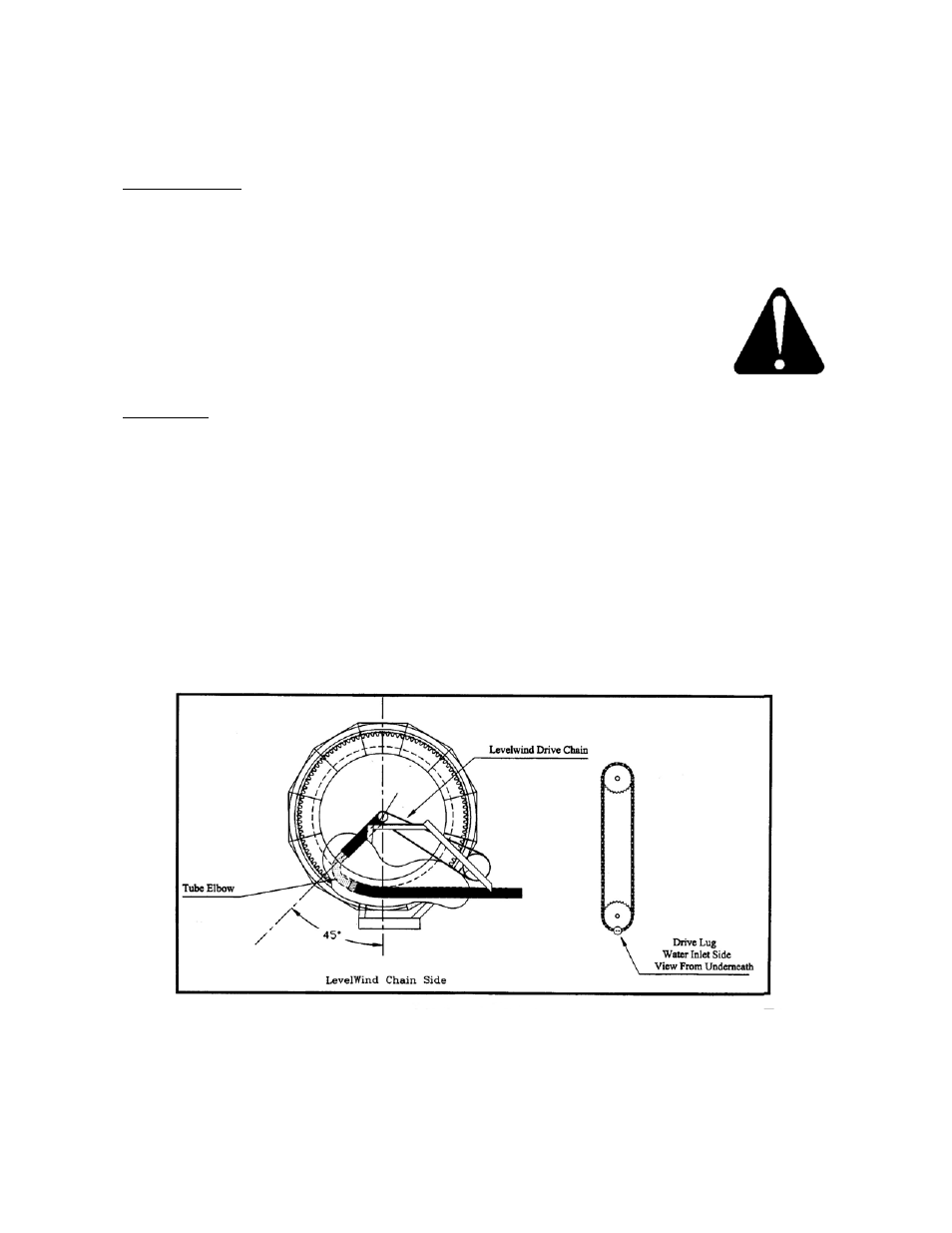

Level Wind Timing

Proper timing of the levelwind mechanism is essential for the successful operation of the Water-Reel. Improp-

er levelwind timing will result in mis-wrapped tube. Travel will be interrupted because the auto compensa-

tion/shut-off bar will stop the drive system in order to prevent damage to the irrigation tube.

Warning! Do not continue to operate if the tube is not winding properly! Operation of a

machine that is not winding properly may result in machine damage or personal injury.

IMPORTANT! If the machine levelwind appears to be malfunctioning, be positive that the levelwind timing is

really at fault before attempting to change the timing. If the tubing is loose on the spool the levelwind system

will appear to be out of time. Possible reasons and solutions are:

1. Tube coils were not packed tightly on drum when operation was started. This can be caused by consist-

ently making partial runs (more than 1 layer of tube remaining on drum) or by ignoring loose coils at

startup.

2. Tube egg shaping or deformation (bottom layer) due to winding via engine or PTO while the tube is not

under pressure. This can be fixed by pulling all the tube out, pressuring the tube up with water and allow-

ing the sun to warm the tube until its shape is regained.

The only way to verify timing is to follow the instruction below:

28