Polyethylene, Assembly, Tube – Kifco E23 360,000 - Present: Operator Manual User Manual

Page 11: Precautions for handling

T23_AA_Operator Manual_2014

Revised 08/2014

Polyethylene

Tube

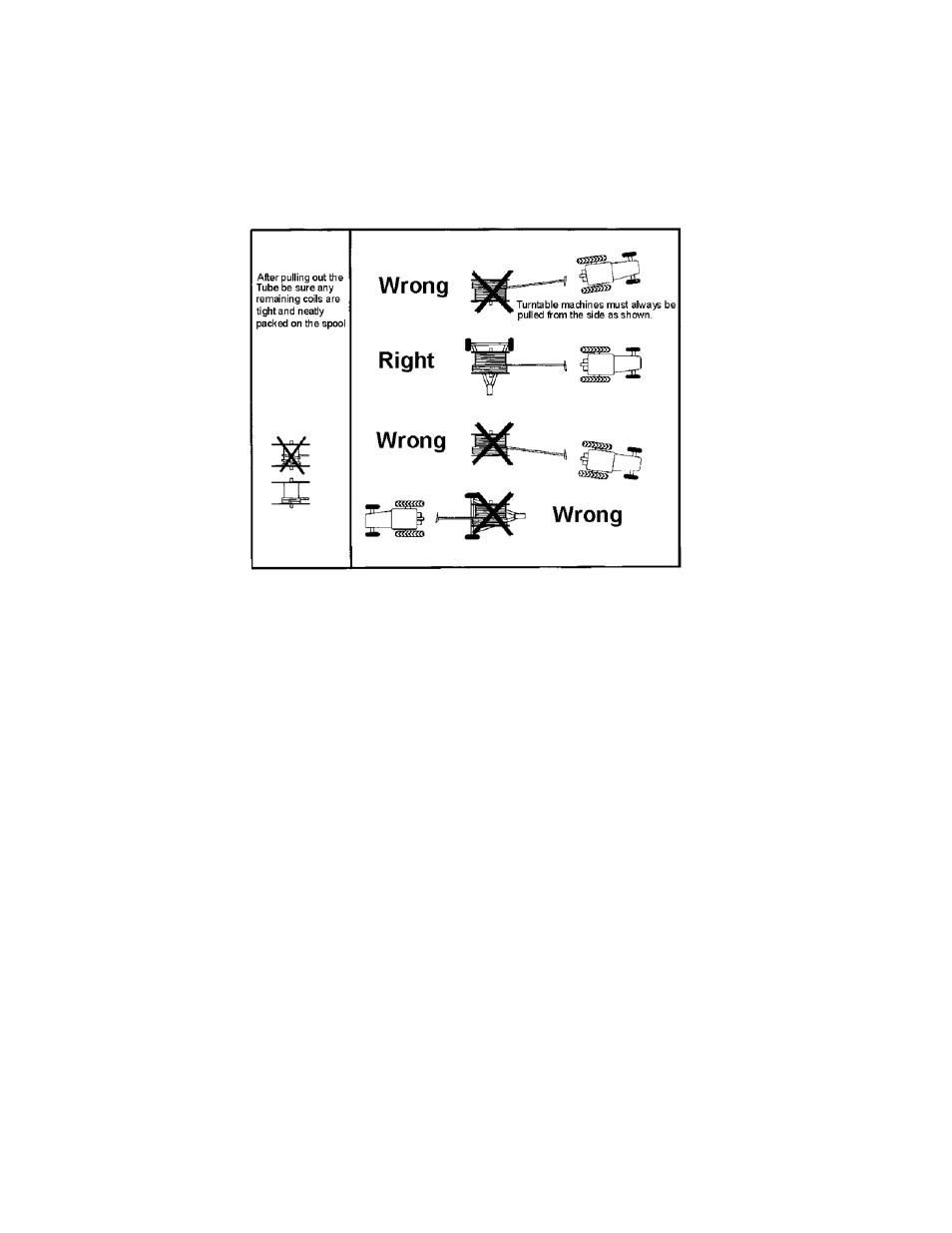

Precautions for Handling

If your machine is exhibiting signs of miswrapping, or loose tube see the Maintenance Section, Page 28.

Note: If the tube is pulled out in an arc to follow a contour or to avoid an obstacle, the arc should be very

gradual. The arc should not begin until at least 20% of the tube is first pulled out straight from the machine.

Under no circumstances should the tube curve more than 90 degrees in its entire length. How well the tube

will follow its laid out path back to the machine will depend mostly on the surface of the ground. For exam-

ple, if there are contours or furrows to follow, the tube may track back very well. If the soil or vegetation is

slippery and no rows or furrows exist, the tube may slide sideways across the laid out path and the sprinkler

cart will be recoiled back to the machine in a straight line instead of following the intended arc. This will place

an excessive side load on the level wind mechanism and may result in equipment failure or tube damage.

Assembly

Water-Reels are usually shipped with the primary assembly complete. The only items to assemble at the desti-

nation are as follows:

1. Wheels. Make sure all lug bolts and axle adjustment bolts are tight. They must be rechecked after being

towed for any distance greater than one mile.

2. Sprinkler Cart. Attach the sprinkler cart to the tube end.

3. Sprinkler. Install on the sprinkler cart riser pipe.

4. Sprinkler Nozzle. Install the appropriate sprinkler nozzle.

Final adjustment of the sprinkler cart lift assembly should be made upon completion of the first irrigation run.

The lift hooks should be located directly above the sprinkler cart when the sprinkler cart is completely drawn

up to the compensation/shut-off bar.

8