Loading diagrams – JUMO 909710 Screw-In Thermowells Data Sheet User Manual

Page 3

JUMO GmbH & Co. KG

Delivery address:Mackenrodtstraße 14,

36039 Fulda, Germany

Postal address: 36035 Fulda, Germany

Phone:

+49 661 6003-0

Fax:

+49 661 6003-607

E-mail:

Internet:

www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax:

+44 1279 635262

E-mail:

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

8 Technology Boulevard

Canastota, NY 13032, USA

Phone:

315-697-5866

1-800-554-JUMO

Fax:

315-697-5867

E-mail:

Internet: www.jumo.us

2011-11-01/00073431

Data Sheet 909710 (909721)

Page 3/6

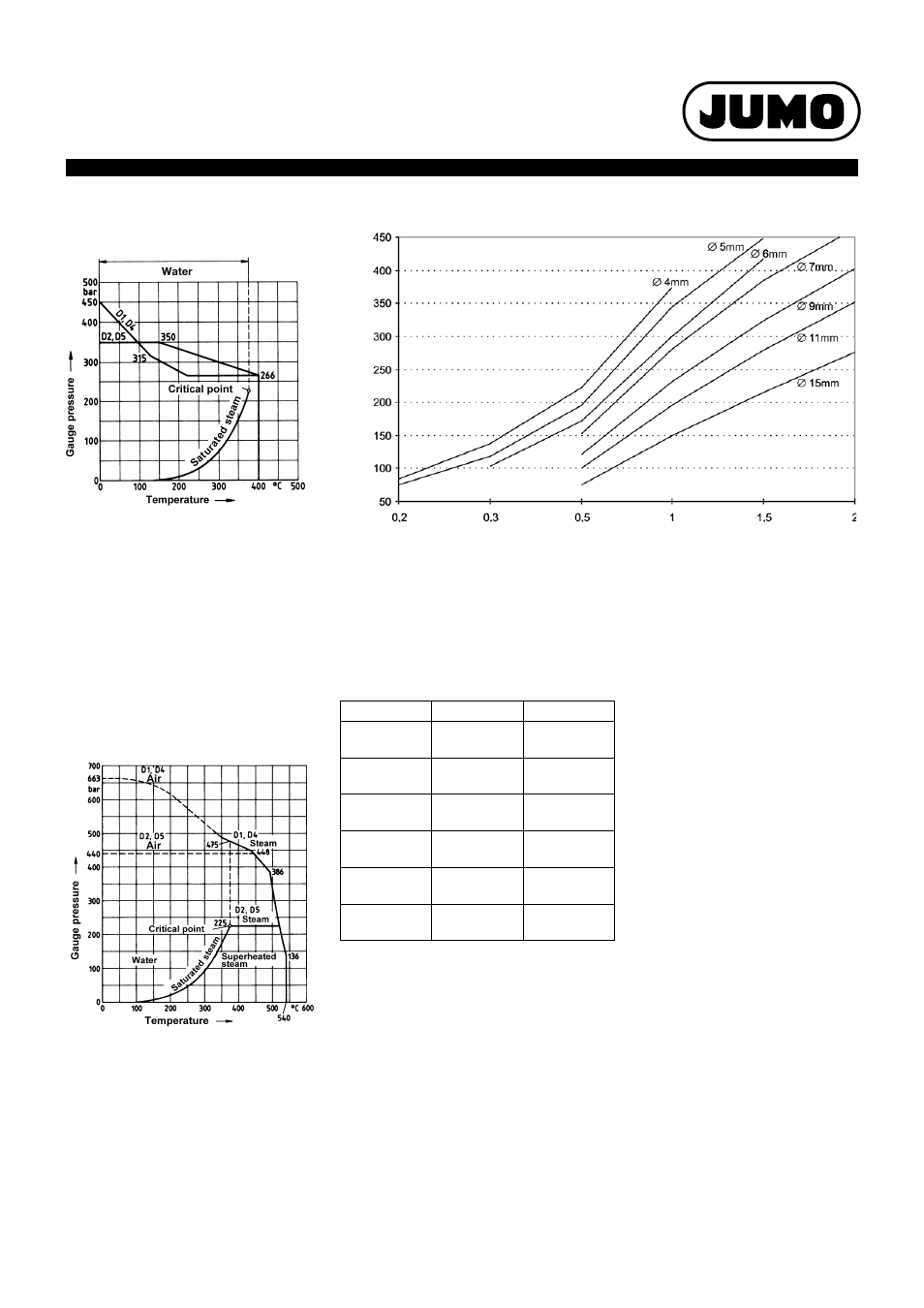

Loading diagrams

Load limits on sheaths, for various sheath dimensions

The diagram shows the load limits (guide values) for different sheath dimensions. The ma-

ximum pressure loading of cylindrical sheaths is shown in relation to the wall thickness with

different sheath diameters. The data refer to sheaths in stainless steel 1.4571, fitting length

100 mm, flow velocity 10 m/sec in air or 4 m/sec in water and a temperature range from -20

to +100 °C. A safety factor of 1.8 has been taken into account. For higher temperatures, or

different materials, the maximum pressure loading has to be reduced by the percentage valu-

es given in the table.

Loading of sheaths

Form D according to 43763

Basic type 909712/50 and /51

Sheath: st. steel X6 CrNiMoTi 17 12 2,

Material Ref. 1.4571

Sheaths D1 and D4:

Permissible flow velocity for

air, water, superhtd. steam: up to 60 m/sec

Sheaths D2 and D5:

Permissible flow velocity

for air: up to 60 m/sec

for water, superheated steam: up to 30 m/sec

Loading on sheaths

Form D according to 43763

Basic type 909712/50 and /51

Sheath: steel 13 CrMo 44,

Material Ref. 1.7335

Permissible flow velocity for

air and superheated steam: up to 60 m/sec

Loading in water: up to 450 bar

and up to 5 m/sec

Wall thickness in mm

Pr

es

sur

e

lo

adi

n

g in ba

r

Material

Temperature

Reduction

CrNi

1.4571

up to +200 °C

-10 %

CrNi

1.4571

up to +300 °C

-20 %

CrNi

1.4571

up to +400 °C

-25 %

CrNi

1.4571

up to +500 °C

-30 %

CuZn

2.0401

up to +100 °C

-15 %

CuZn

2.0401

up to +175 °C

-60 %