Preparations 5.1. installation – JULABO FK31-SL Calibration Baths User Manual

Page 19

SL

19

5. Preparations

5.1. Installation

Place the unit on an even surface on a pad made of non-flammable

material.

Cooling machine, pump motor and electronics produce intrinsic heat that

is dissipated via the venting openings! Never cover these openings!

Keep at least 20 cm of open space on the front and rear venting grids.

The place of installation should be large enough and provide sufficient

air ventilation to ensure the room does not warm up excessively because

of the heat the instrument rejects to the environment. (Max. permissible

ambient temperature: 40 °C).

For a fault (leakage) in the refrigeration system, the standard EN 378

prescribes a certain room space to be available for each kg of

refrigerant.

The refrigerant quantity is specified on the type plate.

> > For 0.25 kg of refrigerant R134a, a room space of 1 m

3

is required.

Do not set up the unit in the immediate vicinity of heat sources and do

not expose to sun light

Before operating the unit after transport, wait about one hour after setting

it up. This will allow any oil that has accumulated laterally during

transport to flow back down thus ensuring maximum cooling

performance of the compressor.

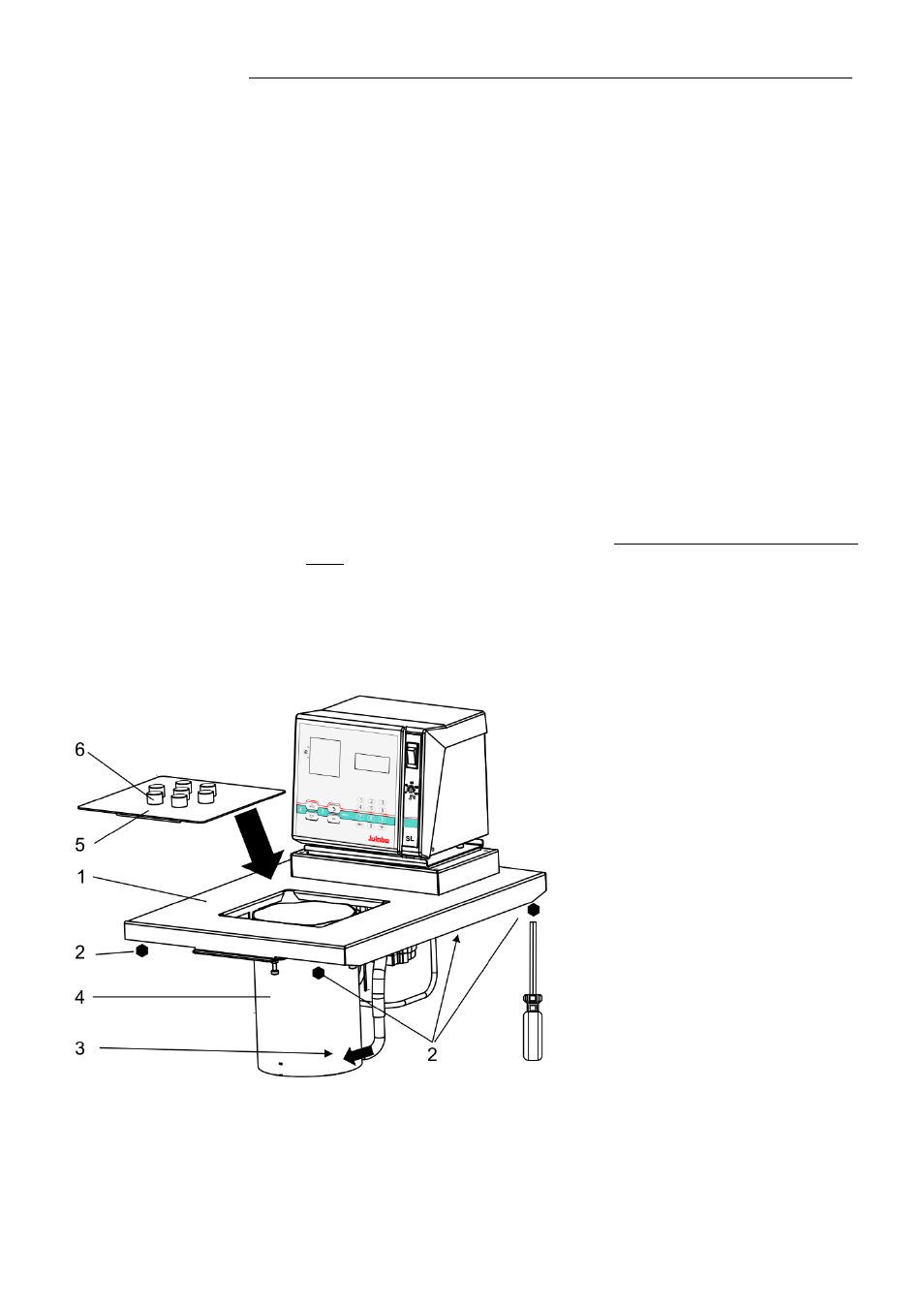

The bath cover (1) is mounted on the bath tank with 4 captive screws (2).

Required tool: SW3 hexagonal socket wrench with ball-shaped head

The circulating pump transports the

bath fluid to the temperature chamber

(4) at the bottom (3). The overflow on

top of the chamber ensures a constant

fluid level during operation.

The bath cover (5) provides 6

measuring places (6) that can be fitted

with different Viton

®

sleeves..

Order-No.: Viton

®

sleeves

8 930 602

2 mm inner dia.

8 930 603

3 mm inner dia.

8 930 604

4 mm inner dia.

8 930 605

5 mm inner dia.

8 930 605

6 mm inner dia.

8 930 608

8 mm inner dia.

Take off the complete insert for cleaning. The gasket below the bath

cover should be replaced in this case.

Part No.: 7.901.1088 Gasket for bath cover FK30, FK31