Warning, Concentric termination, Vent termination clearances – Bryant 4-WAY MULTIPOISE 359AAV User Manual

Page 31: Vertical & horizontal termination

31

CONCENTRIC TERMINATION

Vent Termination Clearances

CARBON MONOXIDE POISONING, FIRE AND

EXPLOSION HAZARD

Failure to follow this warning could result in personal injury,

death, or property damage.

Inlet and outlet pipes may NOT be vented directly above each

other (standard vent terminals).

!

WARNING

1. Determine termination locations based on clearances spe-

cified in following steps and as shown in Fig. 7, Fig. 30

through Fig. 35.

2. The vent termination must be located at least 12″ (305

mm) above ground or normally expected snow accumula-

tion levels.

3. Do NOT terminate over public walkways. Avoid areas

where condensate may cause problems such as above

planters, patios, or adjacent to windows where steam may

cause fogging.

4. The vent termination shall be located at least 4′ (1.2 M)

horizontally from any electric meter, gas meter, gas regu-

lator, and any relief equipment. These distances apply

ONLY to U.S. installations.

5. The vent termination is to be located at least 3′ (.91 M)

above any forced air inlet located within 10′ (3.1 M); (3.1

M) and at least 10′ (3.1 M) from a combustion air intake of

another appliance, except another direct vent furnace in-

take.

6. In Canada, the Canadian Fuel Gas Code takes precedence

over the preceding termination instructions.

Concentric Vent Termination - Kit #

KGAVT0701CVT & KGAVT0801CVT

These kits are for vertical or horizontal termination of the

combustion air inlet and the exhaust vent pipes on Category IV

gas--fired condensing furnaces. The KGAVT0801CVT kit can be

used for 3″ (76 mm) diameter pipe systems. The

KGAVT0701CVT kit can be used for 2″ (51 mm) diameter pipe

system. Refer to Table 4 for the correct pipe size for the furnace.

Both the combustion air inlet and the exhaust vent pipes must

attach to the termination kit. The termination kit must terminate

outside the structure and must be installed per the instructions

outlined below for vertical or horizontal termination. Vertical

termination is preferred. Field supplied pipe and fittings are

required to complete the installation.

Vertical & Horizontal Termination

1. Determine the pipe diameters required for the installation

from Table 4 and Fig. 32.

2. Determine the best location for the termination kit. See

Fig. 31 for vertical termination or Fig. 35 for horizontal

termination. Roof termination is preferred since it is less

susceptible to damage, has reduced intake contaminants

and less visible vent vapor. For side wall termination, con-

sideration should be given to: 1) possible damage from the

vapors to plants/shrubs, other equipment and building ma-

terials, 2) possible damage to the terminal from foreign ob-

jects, 3) wind effects that may cause recirculation of flue

products, debris or light snow and 4) visible vent vapor.

3. Cut one 5″ (127 mm) diameter hole through the structure

for the KGAVT0801CVT Kit or one 4″ (102 mm) diamet-

er hole for the KGAVT0701CVT Kit .

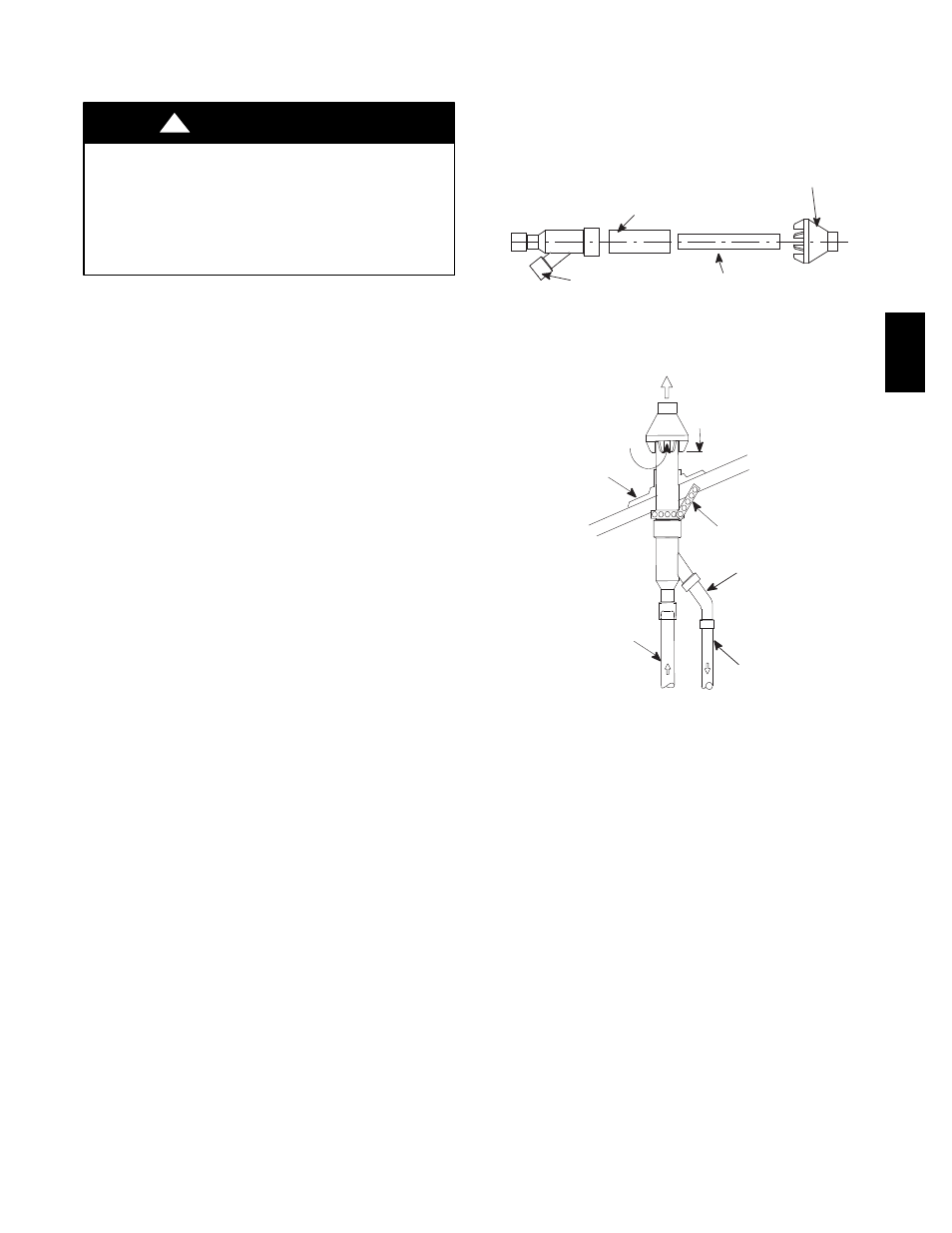

Dia. SDR--26 Pipe

2 in. (51) or 3 in. (76) Dia.

Rain Cap

Y Concentric Fitting

Kit Contents:

3 in. (76) Rain Cap or 2 in. (51) Rain Cap

3 in. (76) Diameter SDR-26 Pipe, 19-1/2 in. (495) Long or

4 in. (102) Diameter SDR-26 Pipe, 24 in. (610) Long,

2 in. (51) Diameter SDR-26 Pipe, 31-5/8 in. (803) Long or

2-1/2 in. (64) Diameter SDR-26 Pipe, 37-1/8 in. (943) Long,

3 in. (76) Y Concentric Fitting or 2 in. (51) Y Concentric Fitting

Nominal 3 in. (76) or 4 in. (102)

Dia. SDR-26 Pipe

2 in. (51) or 2-1/2 in. (64)

2 in. (51) or 3 in. (76) Dia.

A07719

Fig. 30 -- Kit Components

Vent

Maintain 12 in. (304.8mm) min. clear-

ance above highest anticipated

snow level. Max. of 24 in. (609.6mm)

above roof.

Combustion

Air

Roof Boot/

Flashing

(Field Supplied)

Combustion

Air

Vent

Support

(Field Supplied)

45

° Elbow

(Field Supplied)

25--22--02

Note:

Support must be field installed to secure termination kit to structure.

A07720

Fig. 31 -- Concentric Vent Roof Installation

4. Dimension D may be lengthened to 60″ (1524 mm) max.

or shortened by cutting the pipes to 12″ (305 mm) min.

Dimension A will change according to D dimension. (See

Fig. 32).

5. Partially assemble the concentric vent termination kit.

Clean and cement the parts using the procedures for Join-

ing Pipe and Fittings section of the manual. A) Cement the

Y Concentric fitting to the longest of the two straight kit

pipes. (See Fig. 30) B) Cement the rain cap to the shortest

of the straight kit parts. (See Fig. 30).

NOTE: A field supplied stainless steel screw may be used to

secure the rain cap to the pipe instead of cementing when field

disassembly is desired for cleaning (See Fig. 33).

359AA

V