INFICON VSA200 absolute switch User Manual

Vacuum switch, Safety, Technical data

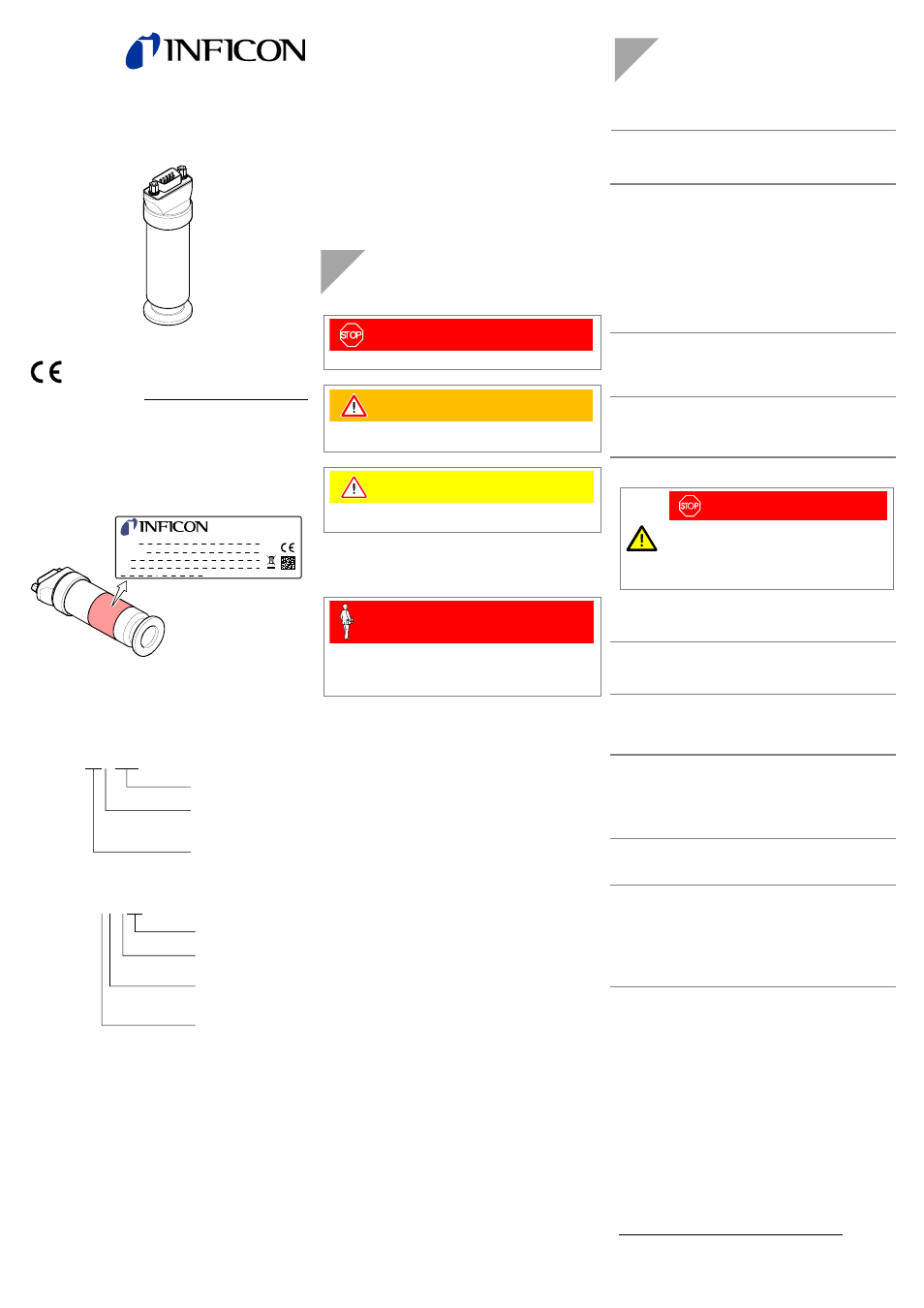

Vacuum Switch

VSA200, VSD200

Operating Manual

Incl. EC Declaration of Conformity

tina65e1 (2011-01)

Product Identification

In all communications with INFICON, please specify the in-

formation on the product nameplate. For convenient refe-

rence copy that information into the space provided below.

Model:

Set point:

PN:

SN:

V W

LI-9496 Balzers

Validity

This document applies to products with the following part

numbers:

VSA200

3SA1-xxx-xxx0

Set-point value

F5

⇒ 1000

Torr

G6

⇒ 1100 mbar

Unit

Flange 1 ⇒ DN 16 ISO-KF

C

⇒

4 VCR male

D

⇒

4 VCR female

VSD200

3SD1-Mxx-xxx0

Setpoint value

Flange 1 ⇒ DN 16 ISO-KF

C

⇒

4 VCR male

D

⇒

4 VCR female

A

⇒ +

B

⇒ –

Sign

5

⇒

Torr

6

⇒ mbar

Unit

The part number (PN) can be taken from the product name-

plate.

If not indicated otherwise in the legends, the illustrations in

this document correspond to the vacuum switch with vacuum

connection DN 16 ISO-KF. They apply to vacuum switches

with other vacuum connection by analogy.

We reserve the right to make technical changes without prior

notice.

All dimensions in mm.

Intended Use

The vacuum switches have been designed for the use in

vacuum systems as absolute pressure switch (VSA200) or as

differential pressure switch (VSD200) in different measure-

ment ranges.

Trademark

VCR

®

Swagelok Marketing Co.

Safety

Symbols Used

DANGER

Information on preventing any kind of physical injury.

WARNING

Information on preventing extensive equipment and envi-

ronmental damage.

Caution

Information on correct handling or use. Disregard can lead

to malfunctions or minor equipment damage.

Personnel Qualifications

Skilled personnel

All work described in this document may only be carried out

by persons who have suitable technical training and the

necessary experience or who have been instructed by the

end-user of the product.

General Safety Instructions

• Adhere to the applicable regulations and take the nec-

essary precautions for the process media used.

Consider possible reactions between the materials and the

process media.

• Adhere to the applicable regulations and take the neces-

sary precautions for all work you are going to do and con-

sider the safety instructions in this document.

• Before beginning to work, find out whether any vacuum

components are contaminated. Adhere to the relevant re-

gulations and take the necessary precautions when hand-

ling contaminated parts.

Communicate the safety instructions to all other users.

Liability and Warranty

INFICON assumes no liability and the warranty becomes null

and void if the end-user or third parties

• disregard the information in this document

• use the product in a non-conforming manner

• make any kind of interventions (modifications, alterations

etc.) on the product

• use the product with accessories not listed in the product

documentation.

The end-user assumes the responsibility in conjunction with

the process media used.

Gauge failures due to contamination or wear and tear, are not

covered by the warranty.

Technical Data

Measurement range

VSA200 (absolute)

1100 mbar (F.S.)

1000 Torr (F.S.)

VSD200 (relative to atm)

-100 … +50 mbar, Torr

Setpoint (setting range)

VSA200

30 … 1060 mbar

20 … 970 Torr

VSD200

-99 … +46 mbar, Torr

Switching contact

changeover contact, floating

Hysteresis

2 % above setpoint

Contact rating

Switching

characteristics

1)

30 V, 1 A DC

125 V, 0.3 A AC

Low Trip Point

Accuracy

≤0.5 % F.S.

Resolution 10

bit

Switching frequency

0.5 Hz

Response time

≤45 ms

Temperature effect on zero

and span

≤±0.02 % F.S. / 1K

Long-term stability

≤±0.5 % F.S. / a

Effect supply voltage

≤±0.005 % F.S. / V

Starting time

1 s

Service live

Electronic

Relay

>1×10

8

cycles

25'000 h

>3×10

6

cycles

Supply

DANGER

The vacuum switch may only be connected to

power supplies, instruments or control devices

that conform to the requirements of a grounded

extra-low voltage (SELV). The connection to the

vacuum switch has to be fused.

Supply voltage

+14 … +30 VDC

Current consumption

≤15 mA

Power consumption

≤0.5 W

Electrical connection

D-Sub, 9 pin, male

Cable

6 pin plus shielding

Cable length

≤100 m (8×0.14 mm

2

)

Materials exposed to

vacuum

Housing

Diaphragm

1.4571, 1.4404

1.4435

Internal volume

DN 16 ISO-KF

4 VCR

®

2.81 cm

3

0.93 cm

3

Admissible pressure (abs.)

VSA200

VSD200

5 bar

2 bar

Admissible temperatures

Operation

Storage

0 … +70 °C

–40 … +80

Relative humidity

≤80 at temperatures up to

≤+31 °C, decreasing to 50

at +40 °C

Use

indoors only, altitude up to

4000 m NN

Mounting orientation

any

Degree of protection

IP40

1)

The switching characteristics and the setpoint can be

programmed via the serial interface (pin 6, 7, 8).