Bcg450-sp, General information, Technical data bcg450-sp – INFICON BCG450-SP ATM to Ultra-High Vacuum Triple Gauge (Profibus) User Manual

Page 3: Power connection, Operation

BCG450-SP

General Information

The BCG450-SP gauge has a fieldbus interface

that conforms to the Profibus DPV1 standard

(

→ [9]).

Via this interface, the following and further data

are exchanged in the standardized Profibus proto-

col (

→ [1], [2]):

• Pressure reading

• Pressure unit (mbar, Torr, Pa)

• Degas function

• Status and error messages

Two adjustable switching functions are integrated in the

gauge. With the built-in atmosphere switching function an

atmospheric pressure thresold can be programmed

(

→ [2]). The corresponding relay contacts are available at

the sensor cable connector.

The basic sensor and sensor electronics of the BCG450-SP

type are the same as in the standard BCG450 (

→ [1], [2]).

Technical Data BCG450-SP

General technical data of the sensor and sensor

electronics

→ [1], [2].

Fieldbus Interface

Fieldbus name

Profibus

Standard applied

→ [9]

Communication protocol,

data format

→ [4], [9]

Interface, physical

RS485

Profibus Parameters

Data rate

≤12 Mbaud (

→ [4], [9])

Node address

00 … 7D

hex

(0 … 125

dec

)

(default 5C

hex

)

Profibus connection

D-Sub, 9-pin, female

Cable

Shielded special Profibus

cable (

→ [7], [9])

Cable length, system wiring

According to Profibus

specifications

(

→ [7], [9])

Supply Voltages

Supply voltage at sensor cable

connector, Pin 8

+24 VDC (+20 … +28 V)

Power consumption

<20 W

Sensor Cable Connection

For reasons of compatibility, the expression "sensor

cable" is used in this document, although the pres-

sure reading of the SD-type gauge is normally

transmitted via the DeviceNet interface.

Connector

D-Sub, 15-pin, male

Cable Max.

15

conductors,

shielded

Cable length, (conductor cross

section per conductor)

≤35 m (0.25 mm

2

)

≤50 m (0.34 mm

2

)

≤100 m (1.0 mm

2

)

Switching functions

2

Setpoints adjustable via

potentiometers (Setpoints

A and B), one floating,

normally open contact per

setpoint

Relay contact rating

≤60 VDC, ≤0.5 ADC

Atmosphere switching function

→ [2]

Gauge identification

42 k

Ω between Pin 10

and Pin 5 (sensor cable)

Grounding principle

→ "Power Connection"

Dimensions

Housing and vacuum connection

→ [1], [2]

Weight

353-554

353-556

≈445 g

≈710 g

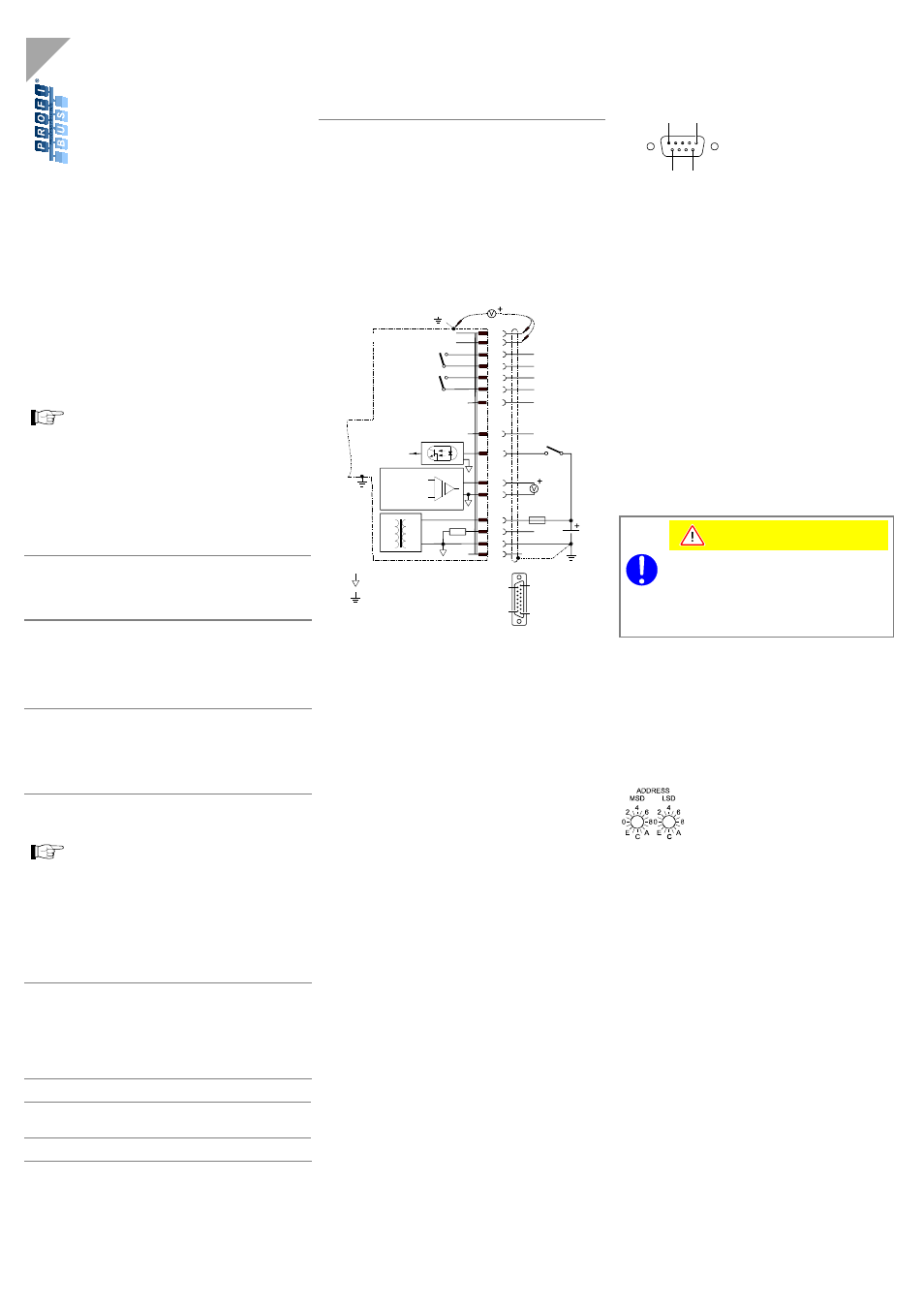

Power Connection

Sensor Cable Connection

Make sure the vacuum connection is properly made

(

→ [1], [2], "Vacuum Connection").

n

If no sensor cable is available, make one according to

the diagram.

Common (power GND 24V supply)

Ground (housing, vacuum connection)

SP A

SP B

SP A

2)

SP B

2)

Degas

42 k

Ω

3

6

1

4

9

11

13

14

7

8

2

12

5

15

1.25 AT

24V

Degas

Ident.

10

-

Threshold values

-

-

1)

( )

+

-

Measuring

signal

-

D-Sub,15-pin,

female,

soldering side

8

9

1

15

Electrical Connection

Pin 1

Relay switching function A, n.o. contact

2)

Pin 2

Measuring signal output

0 … +10.13 V

Pin 3

Threshold (setpoint) A

1)

0 … +10 V

Pin 4

Relay switching function A, com contact

2)

Pin 5

Supply common

0 V

Pin 6

Threshold (setpoint) B

1)

0 … +10 V

Pin 7

Degas on, active high

0 V/+24 V

Pin 8

Supply +24

V

Pin 9

Relay switching function B, n.o. contact

2)

Pin 10

Gauge identification

Pin 11

Relay switching function B, com contact

2)

Pin 12

Measuring signal common

Pin 13

Do not connect

Pin 14

Do not connect

Pin 15

Do not connect

1)

Do not connect pin 3 and pin 6 for normal operation

of the gauge. These pins are reserved for adjust-

ment of the setpoint potentiometers (

→ "Setting the

Switching Functions").

2)

Reprogrammable for atmosphere switching function

via fieldbus interface (

→ [2]).

o

Connect the sensor cable to the gauge and secure the

sensor cable connector using the lock screws.

Profibus Cable Connection

n

If no Profibus cable is available, make one according to

the following indications:

1

5

6

9

D-Sub, 9-pin, male

soldering side

Pin 1

do not connect

Pin 2

do not connect

Pin 3

RxD/TxD-P

Pin 4

CNTR-P

1)

Pin 5

DGND

2)

Pin 6

VP

2)

Pin 7

not connected internally

Pin 8

RxD/TxD-N

Pin 9

not connected internally

1)

Only to be connected if an optical link module is

used.

2)

Only required as line termination for devices at both

ends of bus cable (

→ [9]).

o

Connect the Profibus cable to the gauge and secure

the Profibus cable connector using the lock screws.

Operation

Caution

Caution: data transmission errors

The attempt to operate the BPG450-SP with the

RS232C interface causes data transmission

errors.

The BPG450-SD must not be operated with the

RS232C interface.

Operating Software

For operating the gauge via the Profibus network, prior in-

stallation of the gauge specific GSD file is required. This

software can be downloaded via internet (

→ [5]).

Note Address Setting

The node address (0 … 125

dec

) is set in

hexadecimal form (00 … 7D

hex

) via the

"ADDRESS", "MSD", and "LSD" switches

(default 5C

hex

). The node address is polled

by the firmware when the gauge is

switched on. If the setting deviates from the

stored value, the new value is taken over

into the NVRAM. If a value >125

dec

(>7D

hex

)

is entered, the node address setting

currently stored in the device remains valid

but it can now be defined via Profibus ("Set

slave Address",

→ [4]).

Adjusting the Gauge

Gauge adjustment is carried out automatically, no manual

adjustment is required required (adjustment of the

atmosphere sensor

→ [2]).

Adjusting the Switching Functions

→ "Adjustment and settings".